Friday, 3:15 PM. Your datacenter’s running smooth. By 4:45 PM, the HVAC compressor has tripped for the third time this month, the server room is climbing toward 85°F, and the single-phase motor is making a sound no motor should make. Your boss wants to know why you didn’t specify three-phase when you had the chance.

That $600 you saved on the single-phase panel? It just cost you a $4,200 emergency service call, plus whatever the compressor replacement will run—if it even survives until Monday.

The choice between single-phase and three-phase panelboards isn’t about preferences or “what you’re used to.” It’s about physics, economics, and whether your equipment will last five years or fifteen. This guide breaks down exactly when each system makes sense, what each actually costs over time, and how to avoid the expensive mistakes that happen when engineers guess instead of calculate.

How Single-Phase and Three-Phase Actually Deliver Power

All modern electrical systems use alternating current (AC)—electricity that reverses direction in a continuous sine wave pattern. The fundamental difference between single-phase and three-phase lies in how many of these waves are working at once.

Single-phase power uses two wires: one “hot” phase conductor and one neutral. The voltage follows a single sine wave that peaks, drops through zero, reverses, peaks again, then drops through zero once more—120 times per second on a 60 Hz system. This creates what engineers call “The Pulsating Problem”: your power delivery literally stops twice every cycle, even if only for milliseconds.

For a light bulb, those gaps don’t matter. For a 10 HP compressor motor trying to maintain constant speed? Those power gaps translate to vibration, heat, and mechanical stress. Single-phase motors need starter windings or capacitors just to overcome these gaps and get spinning. Once running, they’re fighting that pulsating delivery every second they operate.

Three-phase power uses three wires (plus typically a neutral): three separate “hot” conductors, each carrying its own sine wave offset by 120 degrees. Here’s the key: when one phase drops to zero, the other two are at 87% of peak voltage. When one phase hits peak, the others are at 50%. The power delivery never drops to zero—it’s constant, smooth, and continuous.

This isn’t a minor technical detail. It’s the difference between a motor that runs cool and lasts 20 years versus one that runs hot and needs replacement in 7.

Pro-Tip #1: If your motor nameplate shows “Design B” or higher, it expects relatively constant power delivery. Running it on single-phase creates internal stresses the motor wasn’t designed to handle—you’re shortening its lifespan from day one.

Technical Specifications at a Glance

The specifications below aren’t just numbers on a datasheet—they determine conductor sizing, breaker selection, and whether your equipment operates within its design parameters.

| Specifikation | Single-Phase System | Three-Phase System |

|---|---|---|

| Typical Voltages | 120/240V, 120/208V | 208/120V (Wye), 480/277V (Wye), 240V (Delta) |

| Konfiguration av kablage | 2 hot wires, 1 neutral, 1 ground | 3 hot wires, 1 neutral, 1 ground |

| Power Delivery Pattern | Pulsating (drops to zero 120x/sec) | Constant (never reaches zero) |

| Strömförande kapacitet | Lower for equivalent wire gauge | Higher (1.732x advantage) |

| Busbar Arrangement | Two vertical buses (L1, L2) | Three vertical buses (A, B, C) |

| Common Breaker Types | 1-pole (120V), 2-pole (240V) | 1-pole (120/277V), 2-pole (208/480V), 3-pole (3-phase loads) |

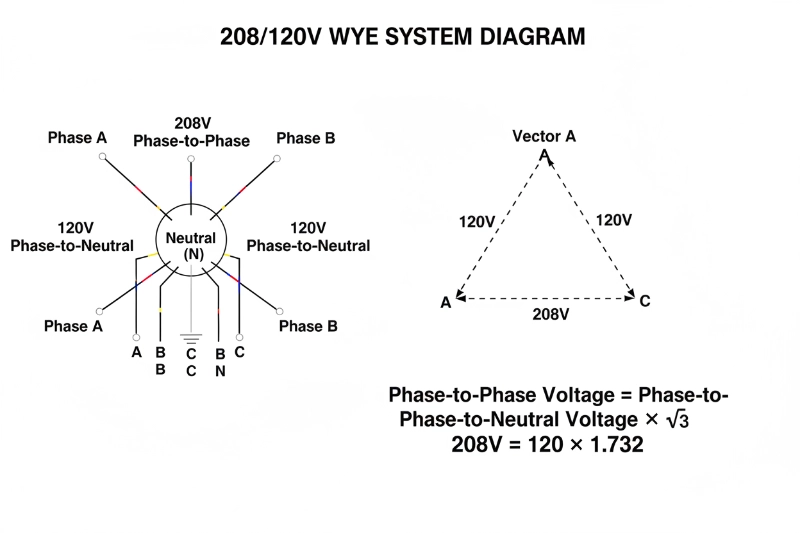

That 208V three-phase voltage confuses engineers every time. Here’s why: each phase-to-neutral reads 120V, same as single-phase. But when you measure phase-to-phase (line-to-line), the 120-degree offset means you don’t get 240V—you get 208V. That’s the √3 (1.732) factor showing up in the real world. A 240V dryer won’t work properly on 208V. A 208V rated load won’t work on 240V delta. Pay attention to nameplate voltages.

Pro-Tip #2: When specifying panelboards for commercial buildings, verify the utility’s actual service voltage. “Three-phase service” could mean 208/120V Wye, 480/277V Wye, or 240V Delta depending on the utility and local infrastructure—each requires different panelboard ratings and breaker types.

Inside the Panel: Why Three-Phase is More Complex

Open a single-phase panelboard and you’ll see two vertical busbars running down the center—Line 1 (L1) and Line 2 (L2)—plus a neutral bus. Simple. Single-pole breakers connect to either L1 or L2 to provide 120V circuits. Double-pole breakers span both L1 and L2 simultaneously for 240V loads like dryers or water heaters. Installation is straightforward: alternate your single-pole breakers between L1 and L2 to balance the load, and you’re done.

Three-phase panelboards are a different animal entirely. You’ve got three busbars (A, B, and C), and now you’re playing what electricians call “The Phase Balance Dance”—the ongoing requirement to distribute loads evenly across all three phases to prevent overloading any single phase and causing system instability.

Here’s what that means in practice:

- Single-pole breakers connect to one phase (A, B, or C) and neutral for 120V or 277V circuits

- Two-pole breakers connect to any two phases (A-B, B-C, or A-C) for 208V or 480V single-phase loads

- Three-pole breakers connect to all three phases (A-B-C) simultaneously for three-phase motors and equipment

The invisible complexity: Let’s say you have 60A of load on Phase A, 58A on Phase B, and 22A on Phase C. Phase C looks fine, but you’re approaching the panel’s rating on A and B. Add one more 20A single-phase load to Phase C? No problem. Add it to Phase A? You might have just overloaded that phase even though the panel’s total capacity shows plenty of room. The panel doesn’t trip on total current—it trips on per-phase current.

Worse, when loads are severely imbalanced, you can get excess neutral current in Wye systems—sometimes even exceeding the phase currents. That neutral conductor you thought was just a safety reference? It’s now carrying significant current and generating heat you didn’t account for in your conduit fill calculations.

The “invisible fourth wire” in three-phase Wye systems: Most engineers think of three-phase as “three hot wires.” But in a 208/120V or 480/277V Wye system, that neutral conductor is the fourth wire that makes single-phase loads possible. It’s not optional, and it’s not just for safety—it’s part of the power distribution path. Size it accordingly.

Pro-Tip #3: When load-balancing a three-phase panel, don’t just look at breaker counts per phase. Look at actual amperage. Three 20A breakers on Phase A pulling 15A each (45A total) is very different from three 20A breakers pulling 2A each (6A total). Use a clamp meter during commissioning to verify actual balance.

Where Each System Belongs (And Where It Doesn’t)

The application table below shows the standard guidelines, but here’s what it really means: if you have motors over 5 HP, large HVAC, or anything that cycles on and off under heavy load, you need three-phase. Period.

| Application Area | Single-Phase | Three-Phase |

|---|---|---|

| Bostäder | Standard for homes, apartments, condos | Rare; only for very large custom homes with workshops or heavy equipment |

| Liten kommersiell | Small offices, retail shops, cafés under 2,000 sq ft | Required if building has large HVAC (>5 tons), walk-in coolers, elevators, or any motor >5 HP |

| Stor kommersiell | Used for lighting and receptacles (120V branch circuits) | Standard for main distribution. Powers HVAC, elevators, pumps, commercial kitchen equipment |

| Industriell | Convenience outlets and office area lighting only | Essential. Powers motors, welders, CNC machines, production lines, material handling |

| Datacenter | Not used for primary distribution | Standard for servers, cooling systems, UPS equipment. Critical for redundancy |

The “overkill” myth dies hard. Engineers routinely hear from contractors that three-phase is “overkill” for a 3,000 sq ft commercial space. Then the HVAC bid comes back specifying a 10-ton rooftop unit with a three-phase compressor, and suddenly you’re Value Engineering the building because you specced a single-phase service and a single-phase panelboard. Three-phase isn’t overkill when your equipment literally won’t run without it.

Small commercial is the danger zone. Restaurants, dental offices, small manufacturing shops—these spaces are large enough to need commercial-grade HVAC and equipment but small enough that developers try to save money on single-phase service. That’s how you end up with a $40,000 phase converter in the mechanical room because the pizza oven requires three-phase and the utility service is single-phase.

If your project includes några of the following, spec three-phase from the start:

- Motors ≥ 5 HP (approximately 18A at 240V, 9A at 480V)

- HVAC systems ≥ 5 tons cooling capacity

- Commercial kitchen equipment (ovens, fryers, hood systems)

- Elevators or material lifts

- Walk-in coolers or freezers

- Welding equipment rated >50A

- Any process equipment with “three-phase” on the nameplate (seems obvious, but you’d be surprised)

The Real Advantages (Beyond the Spec Sheet)

Power Density: The 1.732 Advantage

Here’s the math that makes three-phase worth it: for the same conductor size and amperage, three-phase delivers 1.732 times (√3) more power than single-phase—and you only added one extra conductor.

Example: Two #6 AWG conductors in a single-phase 240V circuit at 50A deliver approximately 12 kW. Four conductors (#6 AWG for three phases plus neutral) in a three-phase 208V Wye circuit at 50A deliver approximately 18 kW. Same wire gauge, one extra conductor, 50% more power.

Alternatively, to deliver 18 kW on single-phase at 240V requires 75A—meaning you’d need #4 AWG conductors (significantly more expensive copper) plus appropriately larger conduit. The 1.732 Advantage means smaller, cheaper conductors for the same power delivery.

Motor Performance: The Compressor Killer

Single-phase motors are brutal on equipment, especially in start-stop applications like HVAC compressors. Here’s what actually happens:

A single-phase motor requires special starter windings or capacitors to create the rotating magnetic field needed to get spinning. Once running, it operates with higher slip (the difference between magnetic field speed and rotor speed), which translates directly to heat. Industry data shows single-phase motors typically run 15-20% hotter than equivalent three-phase motors under the same load.

Three-phase motors? Self-starting. The three offset phases naturally create a rotating magnetic field—no starter windings, no capacitors needed. Lower slip, less heat, simpler construction, longer life.

Concrete numbers: A 10 HP three-phase motor in typical commercial HVAC service averages 15-20 year lifespan. The equivalent single-phase motor averages 7-10 years. That’s not “better durability”—that’s half the replacement cycles and half the service calls. Your $800 three-phase panel just prevented two $6,000 compressor replacements over the building’s first 20 years.

That’s “The Compressor Killer” in action—single-phase power systematically destroys motors that three-phase would have protected.

Pro-Tip #4: For variable-speed drives (VFDs) or any motor that cycles frequently, three-phase isn’t just “better”—it’s essential for reasonable equipment life. VFDs already generate heat and harmonic distortion. Adding the thermal stress of single-phase operation pushes motors beyond their thermal design limits.

Efficiency and Operating Cost

Three-phase systems run more efficiently for high-power loads because:

- Constant power delivery means motors don’t fight pulsating torque, reducing mechanical stress and energy waste

- Smaller conductors for equivalent power mean less resistive losses (I²R heating in wires)

- Balanced loads distribute current evenly, preventing hot spots in distribution systems

- Higher power factors in three-phase systems reduce reactive power penalties from utilities

For a commercial facility running 100 HP worth of motors, the energy savings from three-phase vs. single-phase can approach 8-12% annually. On a $50,000/year electric bill, that’s $4,000-$6,000 in savings—year after year.

Equipment Footprint

Three-phase motors are physically smaller and lighter than single-phase motors of equivalent horsepower. The constant torque delivery means simpler internal construction—no starter windings, smaller frame size, less copper and steel. A 10 HP three-phase motor might weigh 160 lbs in a 256T frame. The single-phase equivalent? 210 lbs in a 284T frame. That’s not just about moving equipment—it affects mounting, structural loading, and installation labor.

What Three-Phase Actually Costs (And Saves)

Initial Cost Reality

Yes, three-phase panelboards cost more upfront. A quality single-phase 200A panelboard might run $350-600. The three-phase equivalent runs $800-1,200. Three-pole breakers cost more than two-pole breakers. Installation labor is higher because load balancing requires more planning.

But here’s the counterintuitive part about conductor costs: while you’re adding a third phase conductor, you’re often sizing down in wire gauge for equivalent power delivery due to The 1.732 Advantage. That means:

- Example 1: Delivering 30 kW to equipment

- Single-phase 240V: Requires 125A, needs #1 AWG conductors

- Three-phase 208V: Requires 83A, needs #3 AWG conductors

- Copper savings per 100 ft run: Approximately $120-150

- Example 2: 50 kW motor load

- Single-phase would require 208A at 240V, #4/0 AWG conductors

- Three-phase requires 139A at 208V, #1/0 AWG conductors

- Copper savings per 100 ft run: Approximately $300-400

For large buildings with 200+ feet of feeder runs, conductor cost savings can partially or completely offset the higher panel and breaker costs.

Lifecycle Economics: The Real Story

Here’s where three-phase pays back hard:

Motor replacement cost avoidance: Using the HVAC compressor example from earlier, avoiding even two premature motor replacements over 20 years saves $12,000-15,000 in parts and labor. That $800 panel premium? Paid back 15-18x over.

Energy savings: A 75 HP motor load (typical for mid-size commercial facility) running 4,000 hours/year:

- Single-phase equivalent: ~$8,200/year in energy costs (assuming $0.12/kWh)

- Three-phase: ~$7,500/year in energy costs

- Annual savings: $700/year

- 20-year savings: $14,000

Reduced maintenance: Three-phase motors require less frequent service. Single-phase motors with starter capacitors need capacitor replacements every 5-7 years ($200-400 each). Three-phase motors? No capacitors to replace.

Total 20-year savings for typical 3,000 sq ft commercial building:

- Motor replacement avoidance: $12,000

- Energy savings: $14,000

- Maintenance reduction: $2,000

- Total: $28,000 savings

- Initial three-phase premium: $1,500

- Net benefit: $26,500

Your $800 panelboard decision just created a 17:1 return on investment.

Pro-Tip #5: When presenting three-phase costs to clients or management, always show the lifecycle analysis—not just upfront costs. Use the client’s actual energy rates and motor inventory for the calculation. A 20-year analysis makes the decision obvious.

The Math: Why 1.732 Changes Everything

The square root of 3 (√3 ≈ 1.732) isn’t arbitrary engineering convention—it’s geometry. Three sine waves offset by 120 degrees form an equilateral triangle relationship in the complex plane. The ratio between the height of that triangle (line-to-line voltage) and the length from center to corner (line-to-neutral voltage) is √3. That’s why 120V phase-to-neutral becomes 208V phase-to-phase in a Wye system (120V × 1.732 = 207.8V, rounded to 208V).

The formulas you’ll actually use:

Single-Phase Power:

P (kW) = (Voltage × Current × Power Factor) / 1,000

Three-Phase Power:

P (kW) = (Voltage × Current × Power Factor × 1.732) / 1,000

That 1.732 multiplier is why three-phase is so much more efficient for power transmission. You’re delivering 73% more power for the same voltage and current—just by using three phases instead of one.

Real-world example:

- Circuit: 480V three-phase, 100A breaker, 0.85 power factor

- Power delivered: 480 × 100 × 0.85 × 1.732 = 70,646W = 70.6 kW

Try delivering 70.6 kW on single-phase 240V:

- Required current: 70,600W / (240V × 0.85) = 346A

- You’d need #600 kcmil conductors and a 400A breaker

Three-phase delivers the same power with #3 AWG and a 100A breaker. That’s The 1.732 Advantage in real copper and real money.

Installation Reality Check

Complexity and Skill

Single-phase panel installation is straightforward: mount the panel, land the feeder, alternate branch Strömbrytare between L1 and L2, balance the loads reasonably, label everything, done. A competent apprentice can handle it with supervision.

Three-phase installations require journeyman-level skills minimum. You’re balancing loads across A, B, and C phases while ensuring that high-current loads don’t all land on the same phase. You’re verifying phase sequence (A-B-C rotation) for three-phase motors—if you land them A-C-B, the motor runs backward. You’re tracking neutral currents in Wye systems to ensure the neutral conductor isn’t overloaded.

Get the phase rotation wrong on a 50 HP pump motor? The pump tries to spin backward against its check valve, the motor draws locked-rotor current, and the breaker trips—if you’re lucky. If you’re unlucky, you damage the pump impeller before anyone realizes the problem.

Phase Identification Matters

NEC 2023 Article 408 requires specific phase identification:

- Common 208/120V Wye: Black (Phase A), Red (Phase B), Blue (Phase C), White (Neutral)

- 480/277V Wye: Brown (Phase A), Orange (Phase B), Yellow (Phase C), Gray (Neutral)

- High-leg delta: The B phase (high-leg at 208V to ground in a 240V delta) must be prominently marked

Color-coding isn’t optional decoration—it prevents someone from accidentally feeding 208V to a 120V load or creating a dangerous phase imbalance.

Safety: The 480V Warning

Single-phase residential 120/240V is dangerous—absolutely. But 480V three-phase is in another category entirely. The arc flash potential and the severity of contact with 480V justifies extreme caution. NEC 2023 requires:

- Available fault current calculations (and labeling) on all panelboards

- Proper PPE during live work (or better: lockout/tagout—LOTO—and work de-energized)

- Proper clearances per NEC Table 110.26(A)(1)

Three-phase 480V systems should only be worked on by qualified electricians with arc flash training and appropriate PPE. This isn’t the place to cut corners.

Can You Run Single-Phase on Three-Phase? (Yes, But…)

Single-Phase Loads on Three-Phase Panels: No Problem

You absolutely can run single-phase loads from a three-phase panel. In fact, that’s standard practice. A single-pole breaker connected to any phase (A, B, or C) and neutral provides 120V or 277V for lights, receptacles, computers, small appliances—anything that runs on single-phase power.

Nearly all commercial buildings have three-phase main distribution but single-phase branch circuits for general lighting and receptacles. This is normal, expected, and perfectly code-compliant.

Three-Phase Loads on Single-Phase Service: Not Happening

The reverse doesn’t work. You cannot run a three-phase motor on single-phase power without conversion equipment. Period.

Your options if you have three-phase equipment but only single-phase service:

- Rotary Phase Converter: A motor-generator set that creates synthetic three-phase power from single-phase input. Works, but adds cost ($1,500-5,000 depending on HP rating), complexity, efficiency losses (10-15%), and another piece of equipment to maintain.

- Variable Frequency Drive (VFD): Some VFDs accept single-phase input and produce three-phase output. Works for motors, adds harmonic distortion, costs $800-3,000, and limits you to variable-speed applications.

- Replace the Equipment with Single-Phase Equivalent: Usually the most expensive option because single-phase motors cost more and perform worse.

If your project has even a 20% chance of needing three-phase equipment, install three-phase service from day one. Phase converters are workarounds for existing buildings where utility three-phase isn’t available—not solutions for new construction where you have a choice.

NEC Requirements You Can’t Skip

All panelboard installations in the United States must comply with the National Electrical Code (NEC), particularly Article 408: Switchboards, Switchgear, and Panelboards. The 2023 edition includes several important requirements:

Circuit Directory and Labeling [408.4]

Every circuit must be clearly and legibly identified in the panelboard directory with sufficient detail to allow identification of its purpose. “Kitchen” isn’t sufficient. “Kitchen Receptacles East Wall” is better. Use a label maker, not a ballpoint pen.

Why it matters: When something trips at 2 AM, the person responding needs to know exactly which circuit controls what—without guessing.

Overcurrent Protection [408.36]

An overcurrent protective device (OCPD) with a rating not exceeding the panelboard rating must protect the panelboard. This can be located within the panelboard (main breaker panel) or on the supply side (main lug only panel fed from upstream protection).

Phase Identification [408.3(E)]

Three-phase bus arrangement must be A-B-C from front to back, top to bottom, or left to right when viewed from the front. On delta systems with a high-leg (B phase at 208V to ground on a 240V delta), the B phase must be prominently field-marked: “Caution: B Phase has 208V to Ground.”

Working Space and Clearances [110.26]

Minimum working space in front of panelboards:

- 0-150V to ground: 3 feet clear

- 151-600V to ground: 3 feet clear (some conditions require 3.5 feet)

- No storage, no obstructions, no “temporary” equipment staged in the clearance zone

This isn’t a suggestion—it’s required for electrical safety and code compliance.

Unused Openings [408.7]

All unused breaker spaces must be closed with listed filler plates. Leaving holes in the deadfront allows accidental contact with energized busbars—an arc flash hazard and code violation.

New in NEC 2023: Maintenance Planning [NFPA 70B Reference]

NEC 2023 now references NFPA 70B (Standard for Electrical Equipment Maintenance), which requires property owners to develop and implement maintenance plans for all electrical equipment, including panelboards. Key requirements include:

- Infrared thermography scans (12-month intervals for critical facilities)

- Regular visual inspections for loose connections, corrosion, damaged components

- Documentation of maintenance activities

- Qualified personnel performing all maintenance

This elevates electrical maintenance from “recommended practice” to mandatory requirement.

Short-Circuit Current Rating (SCCR) [408.6]

Every panelboard must have a marked short-circuit current rating (SCCR) that equals or exceeds the available fault current at its location. For non-dwelling units, the available fault current and calculation date must be field-marked on the panelboard.

This prevents installing a 10kA-rated panel where the fault current might hit 22kA—a recipe for catastrophic failure during a fault condition.

4 Questions That Determine Your Choice

Skip the guesswork. Answer these four questions:

1. What power service is available from the utility?

Check with the local utility before designing anything. Commercial and industrial areas typically offer three-phase service. Residential areas may not, or may charge $5,000-15,000 for a transformer upgrade to provide three-phase.

If three-phase isn’t available or costs prohibitive, your decision is made. If it’s available, continue to question 2.

2. What’s the total facility electrical load?

Calculate the total kVA or amperage per NEC Article 220. The 100A Rule: If your facility’s total load exceeds 100A at 240V (approximately 24 kW), three-phase becomes economically justified for operational efficiency alone—even if you don’t have three-phase equipment yet.

3. What equipment will you be powering?

Go through the equipment list:

- Any motors ≥ 5 HP? → Three-phase required

- Large HVAC systems (>5 tons)? → Three-phase required

- Commercial kitchen equipment? → Check nameplates (often three-phase)

- Elevators, lifts, hoists? → Three-phase required

- Welders, CNC equipment, industrial machinery? → Usually three-phase

If you answered “yes” to any of these, you need three-phase. Not “might benefit from”—need.

4. What are the long-term expansion plans?

Installing three-phase later costs 2-3x more than including it during initial construction. The utility service upgrade, transformer, main distribution panel, and feeder conductors all become change-order expenses plus demolition and patching costs.

If there’s even a reasonable probability of future need (adding production equipment, expanding kitchen, upgrading HVAC), install three-phase now.

Myths That Cost Engineers Money

Myth #1: “You can’t get single-phase power from a three-phase panel”

Reality: Completely false. Single-pole breakers connected to any phase and neutral provide standard 120V or 277V single-phase power. This is exactly how commercial buildings handle lighting and receptacles—three-phase main distribution, single-phase branch circuits.

Myth #2: “Three-phase is always 480V”

Reality: While 480/277V Wye is common in large industrial facilities, 208/120V Wye is the most common three-phase configuration for commercial buildings. Also available: 240V Delta, 120/240V high-leg Delta, and various others. Always verify the actual available voltage before specifying equipment.

Myth #3: “Converting single-phase to three-phase is easy”

Reality: It requires either a rotary phase converter (motor-generator set, $1,500-5,000) or a VFD with single-phase input capability ($800-3,000+), both of which add cost, complexity, efficiency losses, and maintenance requirements. It’s not “easy”—it’s a workaround for situations where three-phase service isn’t available.

Myth #4: “Three-phase is overkill for small commercial”

Reality: If your “small commercial” space has HVAC over 5 tons or any motor over 5 HP, three-phase isn’t overkill—it’s the specification. That 10-ton rooftop unit serving your 3,000 sq ft restaurant? Its compressor is three-phase. The walk-in cooler? Three-phase compressor. “Small commercial” doesn’t mean “residential-grade electrical.”

Myth #5: “Single-phase motors are cheaper”

Upfront? Sometimes, by $200-400. Lifecycle? Not even close. Higher operating costs, shorter lifespan, more frequent service—single-phase motors cost significantly more over their operating life despite lower purchase price.

What’s Changing in Power Distribution

The traditional boundary between residential single-phase and commercial three-phase is blurring, driven by two major trends:

Infrastruktur för laddning av elfordon

Multi-family residential buildings are increasingly installing three-phase service to support high-density Level 2 EV chargers in parking structures. Twenty 7.2 kW Level 2 chargers (144 kW total) would require massive single-phase infrastructure. On three-phase? Manageable.

Smart Panelboards with Energy Monitoring

Modern panelboards increasingly include built-in energy monitoring, remote switching capability, and cloud connectivity for both single-phase and three-phase systems. These systems provide:

- Real-time per-circuit energy monitoring

- Predictive maintenance alerts (thermal trending, connection degradation)

- Demand response capability for utility incentive programs

- Integration with building management systems (BMS)

These smart panelboards cost 15-25% more than standard panels but provide operational visibility that helps identify problems before they become failures—and provide data for energy optimization.

As these trends continue, expect to see three-phase service becoming standard in larger multi-family residential construction and smart monitoring becoming standard in all commercial installations.

Conclusion: Choose Based on Physics, Not Preferences

The choice between single-phase and three-phase panelboards comes down to three factors: the power available, the equipment you’re powering, and the long-term operational costs you’re willing to bear.

Single-phase panelboards serve residential and light commercial applications efficiently and cost-effectively—when loads stay below 100A and no equipment requires three-phase power. They’re simpler to install, less expensive upfront, and completely adequate for their intended use.

Three-phase panelboards are essential for commercial and industrial facilities with motors over 5 HP, large HVAC systems, or any significant mechanical equipment. The higher upfront cost ($800-1,200 vs. $350-600 for panels) is offset by operational savings that compound over 15-20 years: longer motor life, lower energy costs, reduced maintenance, and the ability to use smaller conductors for equivalent power delivery thanks to The 1.732 Advantage.

That $800 panel premium? It prevents premature motor failures (The Compressor Killer), eliminates The Pulsating Problem for rotating equipment, and delivers 73% more power with the same wire gauge. Over 20 years, it creates returns of 15:1 to 20:1 on investment.

The decision framework is straightforward: If your equipment nameplates say “three-phase,” or if your motors exceed 5 HP, or if your total load exceeds 100A, three-phase isn’t optional—it’s the specification. Everything else is just arguing with physics.

As of November 2025, all technical specifications and code references reflect NEC 2023 and current industry standards for power distribution equipment.