8:47 AM. The solar installer pops the latches on the combiner box lid. Inside, six PV strings terminate at බස් බාර්, each waiting for its fuse. He grabs his insulated screwdriver, reaches for the first positive wire, and makes contact. In 0.3 seconds, a 400Vdc arc flash erupts—brighter than a welding torch, hot enough to vaporize copper. His safety glasses melt to his face. The arc sustains itself, feeding on the DC current, until the breaker 50 feet away finally trips. The medical bills: $2,500 for the ER visit. The lost work: three weeks. The lesson: DC doesn’t play by AC rules.

You’ve wired AC panels before. You’ve worked with 240V residential service. You know to turn off the කඩනය. But solar combiner boxes are different. The voltage is higher. The current is relentless. And the arc flash? It doesn’t self-extinguish like AC.

So what’s actually creating this danger? And how do you wire multiple solar panels into a combiner box without turning a routine connection into a career-ending mistake?

The Arc Flash Surprise: Why DC Solar Wiring Is More Dangerous Than You Think

Most electricians learn arc flash danger on AC systems. AC arcs extinguish 120 times per second as the voltage crosses zero. DC arcs? They’ll burn until something melts. This is the Arc Flash Surprise—DC’s silent, self-sustaining violence that makes it far more dangerous than AC at the same voltage.

Here’s the physics that kills: When you separate two conductors carrying DC current, the arc ionizes the air gap. That ionized plasma becomes a low-resistance path. The DC voltage never drops to zero, so the plasma never cools. The arc column grows, feeding on the continuous current, until it reaches temperatures of 35,000°F—hotter than the surface of the sun.

In a solar combiner box, you’re dealing with string voltages of 300-600Vdc. A typical 10-panel string at 40Voc each isn’t 400V. On a cold January morning, that Voc climbs 25% higher—to 500V. Your standard insulated screwdriver rated for 1000V? That’s AC rating. The DC withstand voltage is typically 30-40% lower.

The first rule of DC solar work: If you’re not wearing arc-rated PPE, you’re gambling with your eyesight. Category 2 PPE (8 cal/cm²) is the minimum for most combiner box work. But here’s the trap: That rating assumes you’re working on de-energized equipment. The moment you decide to “just tighten one connection live,” you’re in Category 4 territory (40 cal/cm²)—and a face shield won’t save you from the pressure wave.

The NEC 2023 edition finally woke up to this. Article 690.12 requires rapid shutdown of PV systems, but it doesn’t protect you during installation. That’s on you. And your combiner box wiring method.

The Voltage Stacking Trap: When Your Math Becomes a Safety Hazard

You checked the panel label: 40Voc. You have 8 panels in series. Simple math: 8 × 40V = 320V. Your fuse holder is rated for 600V. Your breaker is rated for 250Vdc. You’re safe, right?

Welcome to the Voltage Stacking Trap.

Here’s what the label doesn’t tell you: Voc (open-circuit voltage) is measured at Standard Test Conditions—25°C (77°F). Your panels on a cold morning? They’re operating at -10°C (14°F). For every degree Celsius below 25°C, Voc rises by 0.3%.

Do the real math: 8 panels × 40Voc × (1 + (35°C × 0.003)) = 8 × 40 × 1.105 = 353.6V. That’s a 10% increase. Still under your 600V fuse holder, but what about your 250Vdc breaker?

Wait—it gets worse. That “250Vdc” breaker? It’s probably AC-rated. Most molded-case breakers in solar combiner boxes are repurposed AC breakers. The DC voltage withstand is often 50% of the AC rating. Your “250Vdc” breaker might only be safe to 125Vdc under sustained DC load.

Your 353V string just became a bomb waiting for the first arc fault.

NEC 690.7 requires you to apply a 1.25 correction factor to Voc for cold temperature calculations. For an 8-panel, 320V nominal string, that’s 400V minimum design voltage. Your 250Vdc breaker is now illegal under 2023 code.

The Voltage Stacking Trap kills more solar installations than any other design error. It doesn’t show up on day one. It shows up on the first cold morning, when the inverter faults out and the installer gets called back to “fix” a problem that isn’t wiring—it’s math.

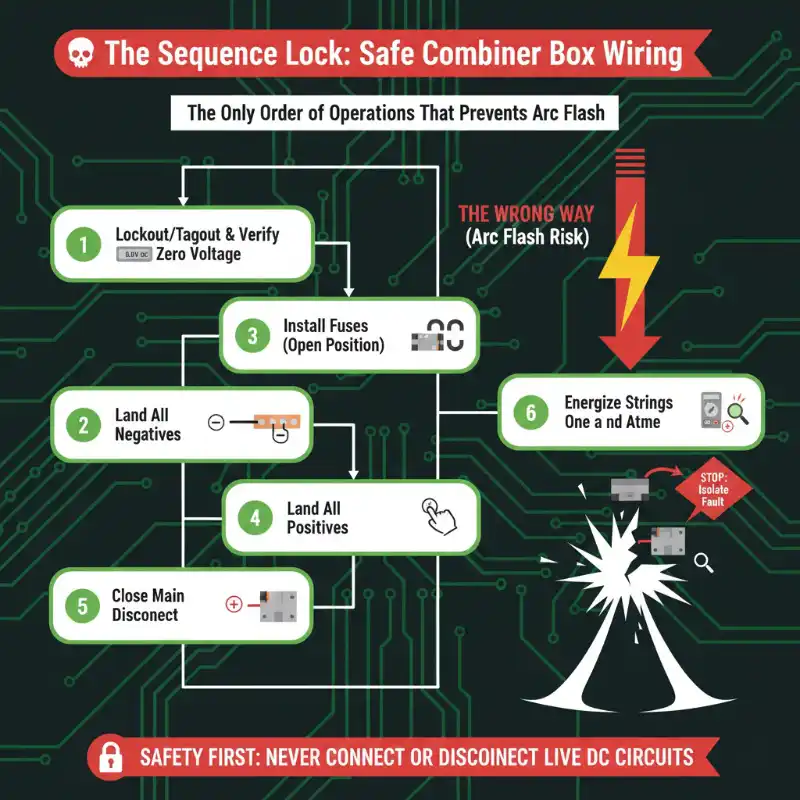

The Sequence Lock: The Order of Operations That Prevents 90% of Accidents

You can have the right PPE. You can calculate voltages perfectly. You can spec the best components. But if you wire the combiner box in the wrong sequence, you’re still going to create a live arc hazard.

This is the Sequence Lock. It’s the order of operations that keeps you safe. And 90% of installers get it wrong.

Here’s the wrong sequence (the one that creates the Arc Flash Surprise):

- Land all the PV string wires on the busbars

- Install the fuses while the strings are live

- Close the disconnect last

Why is this wrong? Because the moment you touch that fuse to a live busbar, you’re creating a hot connection under load. The fuse holder isn’t designed to make connections hot. The arc can jump from the fuse tip to the busbar before the threads engage. You’ve just created a series arc fault at 400Vdc.

Here’s the Sequence Lock—the right way:

- Lockout/Tagout: Verify all strings are disconnected at the panel-level disconnects or module-level rapid shutdown devices. Use a calibrated meter to confirm zero voltage at the combiner box.

- Land the negatives: Connect all PV string negative leads to the negative busbar. This is your reference ground. Do this first, while everything is dead.

- Install the fuses: Insert all DC fuses into their holders, but leave them in the “open” position. Don’t close them yet.

- Land the positives: Connect all PV string positive leads to the line side of the fuse holders. Again, everything is dead.

- Close the disconnect: Close the main combiner box disconnect (if equipped) to energize the busbars.

- Energize strings one at a time: Close each fuse holder individually, verifying voltage and current on your meter before moving to the next. This isolates any fault to a single string.

The Sequence Lock is simple: Never make a connection that could be live. Never break a connection that is live. Always verify zero energy before you touch anything.

NEC 690.16 requires a disconnect means for each string, but it doesn’t tell you how to sequence your work. That’s what separates professional installers from the ones who show up on incident reports.

The 4-Step Method to Wire Solar Panels into a Combiner Box Safely

You’ve got the theory. Now here’s the field-tested method that keeps you safe and keeps the inspector happy.

Step 1: Calculate and Verify String Voltages (Don’t Trust the Label)

Mini-thesis: Label Voc is a starting point, not a design value. Cold-temperature correction and measurement verification are mandatory for NEC 2023 compliance.

Grab the panel datasheet. Find Voc at STC (Standard Test Conditions). Now do the real calculation:

Voc(design) = Voc(STC) × Number of panels × 1.25 (NEC 690.7 cold temp factor)

For your 40Voc panels in strings of 8: 40 × 8 × 1.25 = 400V design voltage.

Now verify it. On a cold morning (<40°F), disconnect the string and measure Voc with a Fluke 393 FC clamp meter (rated for 1500Vdc). You should see 380-420V. If you’re seeing 450V, your string is too long for your equipment. Redesign now, not after the arc flash.

Pro-Tip: The NEC 2023 1.25 factor is a minimum. In Canada or northern states, use 1.35. The inspector will check. Your insurance will too, after a claim.

Step 2: Select Properly Rated Components (The 250Vdc Lie)

Mini-thesis: Component voltage ratings must exceed your design Voc by at least 20%, and DC ratings are not interchangeable with AC ratings.

Your design voltage is 400Vdc. Your component minimum ratings:

- Fuse holder: 600Vdc minimum. Bussmann and Littlefuse make solar-rated holders that can interrupt 10kA at 600Vdc.

- Fuse: 600Vdc, time-delay type. Standard 250V fuses will explode.

- Disconnect: 600Vdc, 20A minimum. Check the DC rating, not the AC rating. A “30A 240V” AC disconnect is probably only 15A 120Vdc.

- Wire: PV wire (USE-2 or RHW-2) rated for 600Vdc. THHN wire is not sunlight-resistant and will crack in 3 years.

The 250Vdc Lie: That breaker labeled “250Vdc”? Read the fine print. It says “250Vdc maximum, 80% duty cycle.” For continuous solar operation (100% duty cycle), you must derate to 200Vdc. Your 400V string just made that breaker illegal.

Use only components listed to UL 1741 for PV applications. The inspector will look for the listing mark. Your alternative is ripping it all out.

Step 3: Execute the Sequence Lock (Never Work Hot)

Mini-thesis: The Sequence Lock is a written procedure, not a mental checklist. Deviation is how arcs happen.

Before you touch the combiner box, write this on the job ticket:

- Verify lockout at panel disconnects. Measure zero voltage.

- Land all negative wires on negative busbar.

- Install fuses in open position.

- Land all positive wires on fuse line terminals.

- Close main disconnect.

- Energize fuses one at a time, verifying each.

Have a second person sign off on each step. This isn’t bureaucracy—it’s how you avoid explaining to a workers’ comp board why you’re missing three fingers.

Pro-Tip: Use a non-contact voltage tester (NCVT) rated for DC before you touch anything. The Fluke 1AC-A1-II won’t detect DC. You need a Fluke 369 FC or similar. A $200 tool beats a $50,000 hospital bill.

Step 4: Torque, Test, and Document (The Finger-Tight Trap)

Mini-thesis: Proper torque is a code requirement, not a suggestion. Loose connections create high-resistance joints that melt under load.

Every busbar connection in your combiner box has a torque spec, typically 50-120 in-lbs. “Finger-tight plus a quarter-turn” is the Finger-Tight Trap—it’ll feel secure today and be a fire hazard in six months.

Use a torque screwdriver or wrench. Set it to the spec. Torque every connection. Then do it again. Thermal cycling loosens connections over time. The NEC 2023 edition added 690.31(C) requiring documented torque verification for all PV connections over 100A. For residential, it’s still a best practice that keeps you off the fire investigator’s report.

Testing: After energizing each string, measure voltage at the combiner box and at the inverter input. They should match within 2V. A bigger drop indicates a bad connection. Fix it now.

Documentation: Take a photo of the completed wiring. Label each string on the photo. Save it in the customer’s file. When they call in three years about “low production,” you’ll know exactly which string is which without opening the box.

Your Combiner Box Should Be Boring

You now understand the Arc Flash Surprise—DC’s silent, relentless danger that makes AC look tame. You’ve escaped the Voltage Stacking Trap—the math error that turns protective devices into bombs. And you’ve mastered the Sequence Lock—the order of operations that keeps you safe when everything else goes wrong.

A properly wired combiner box is boring. It doesn’t spark. It doesn’t hum. It doesn’t get hot. It just sits there, combining strings, protecting circuits, and keeping your solar system running for 25 years.

Your job is to make it boring. Follow the 4-step method. Use rated components. Execute the Sequence Lock. Torque every connection. Document everything.

Ready to spec a code-compliant combiner box for your next project? Download our free NEC 2023 Combiner Box Checklist with torque specs, voltage calculation worksheet, and component selection guide. Or contact a VIOX application engineer for project-specific design support.

Your combiner box should be the most reliable part of the system. Make it so.

Standards & Sources Referenced

- NEC 690.7 (2023): Voltage correction factors for low temperature

- NEC 690.12 (2023): Rapid shutdown of PV systems on buildings

- NEC 690.16 (2023): Fuses and disconnects for PV circuits

- NEC 690.31(C) (2023): Torque documentation requirements

- UL 1741: Standard for safety of inverters, converters, and charge controllers

- UL 4248-18: Fuseholders for photovoltaic systems

- එන්එෆ්පීඒ 70ඊ: Standard for electrical safety in the workplace