You’ve got 10 REC 350W solar panels ready to mount. Five strings of two panels each. Each string pumping out 93.4 volts DC at 9 amps. You’ve researched DIY solar combiner box designs online, and you’ve done the math—everything checks out.

Then you price out a proper solar combiner box. $300. Maybe $400 if you want the one with integrated monitoring. You look at the Square D subpanel sitting in your garage—the one you paid $60 for last year. Same metal box. Same bus bars. Same circuit breakers. Why exactly are you supposed to pay 5× more for what looks like the same thing?

Here’s why: Because that $240 price gap is the difference between a system that works for 20 years and one that catches fire in 6 months.

The Arc That Won’t Die: Why DC Destroys AC Equipment

The moment you flip an AC breaker open under load, an electrical arc forms between the separating contacts. It’s plasma—ionized gas carrying thousands of amps through what used to be air, generating temperatures that hit 35,000°F, which for reference is four times hotter than the surface of the sun.

But here’s the thing about AC arcs: they die on their own.

Sixty times per second, standard AC power crosses through zero volts as the current alternates direction. At that exact moment—lasting just milliseconds—the arc loses its energy source and extinguishes. Contacts keep moving apart. Circuit opens. Done.

DC doesn’t do this.

When you interrupt 93.4 volts DC, that arc lights up and stays lit for as long as the contacts are close enough to sustain it. There’s no zero crossing. No natural interruption. Just continuous, unrelenting current trying to bridge that gap with a river of plasma that melts metal, ignites insulation, and keeps burning until the contacts have physically separated far enough—typically 3-4 times farther than AC equipment is designed for.

This is “The Arc That Won’t Die,” and it’s why every component inside a real DC-rated combiner box looks different from AC equipment. The contact spacing is wider. The arc chutes (those zigzag metal plates that stretch and cool the arc) are longer. Some DC breakers even use magnetic coils to physically blow the arc out, like extinguishing a candle.

Your $60 AC subpanel has none of this.

Its breakers are designed assuming the arc will naturally extinguish within 8 milliseconds. Put 93 volts DC through them, and that assumption becomes a liability. The contacts try to open, the arc forms, and instead of dying at the zero-crossing, it just… continues. The breaker’s arc chutes aren’t long enough. The contact separation isn’t wide enough. The materials aren’t rated for sustained DC arcing.

Eventually, one of two things happens: the contacts weld together (permanently closing the circuit even when you think it’s “off”), or the breaker’s internal components melt and fail catastrophically. Neither outcome involves your solar system shutting down safely when you need it to.

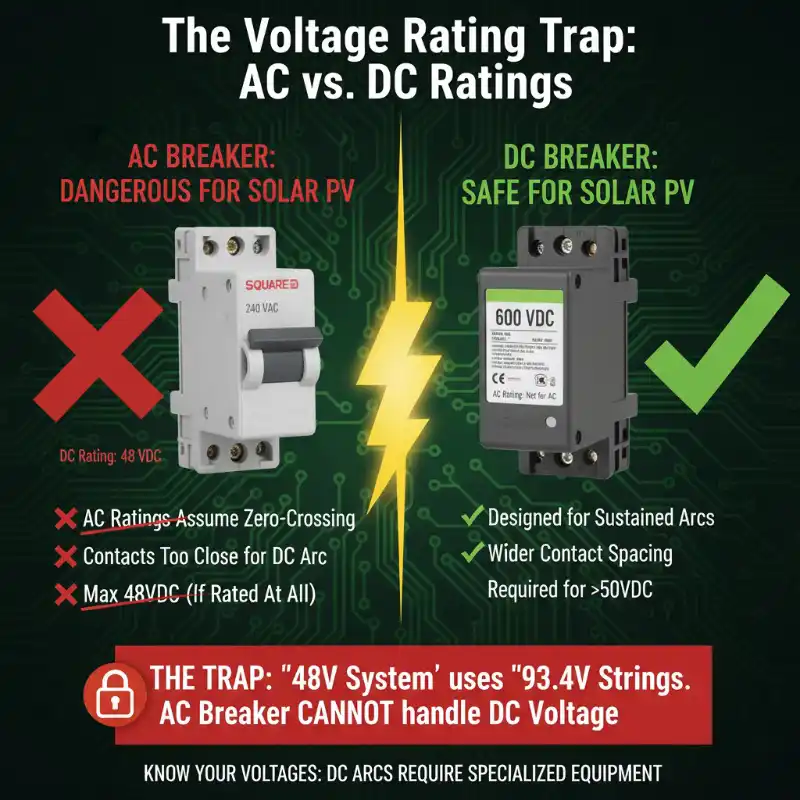

The 48V Confusion: Your Battery Voltage ≠ Your String Voltage

This is where most DIY solar combiner box plans go sideways.

You see “48V system” in your planning documents. You find an AC subpanel rated for “48 volts.” Perfect match, right?

Wrong on three counts.

First: That 48V battery rating is the nominal voltage—the average operating point. Your 48V battery actually operates between 40V (discharged) and 58V (charging). Not relevant for combiner box sizing, but important to know the numbers move around.

Second: Your solar strings don’t care what voltage your batteries run at. Each REC 350W panel has an open-circuit voltage (Voc) of 46.7V. Two panels in series? That’s 93.4 volts—nearly double your battery voltage—and that’s the number your DIY combiner box has to handle. You’re not combining 48V; you’re combining five separate 93.4V strings into one DC output circuit.

Third—and this is The Voltage Rating Trap: When an AC-rated panel says “48 volts,” it means 48 volts ඒසී. If it has any DC rating at all (most don’t), it’s buried in the fine print and dramatically lower. A breaker rated for 240VAC might only be safe to 48VDC. A panel rated for 480VAC? Maybe 60-80VDC if you’re lucky.

Why the massive difference? Back to The Arc That Won’t Die. AC voltage ratings assume the arc extinguishes naturally. DC voltage ratings assume the arc fights back and tries to sustain itself across wider gaps. The higher the DC voltage, the wider the gap it can jump, and the more robust the interrupting mechanism needs to be.

So that Square D panel “rated for 48V”? Even if that’s a DC rating (check the datasheet—I’ll wait), you’re trying to push 93.4V through it. You’re operating at 195% of its design voltage. That’s not a safety margin; that’s a countdown timer.

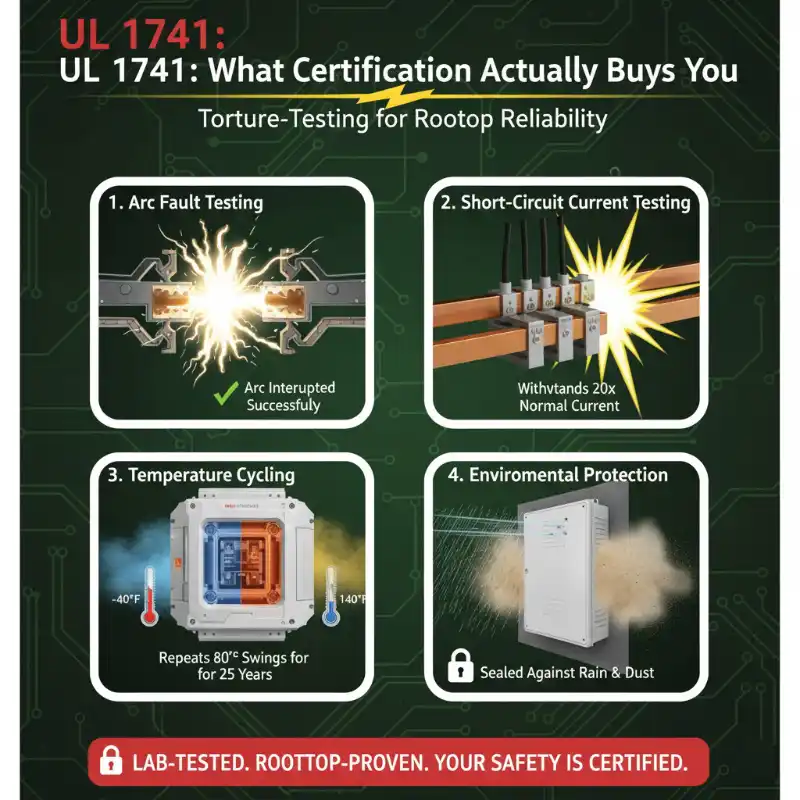

What $240 Actually Buys You: Inside UL 1741 Certification

“It’s just a UL sticker,” you might think. “I can skip that for a DIY setup.”

But UL 1741—the standard for solar combiner boxes and interconnection equipment—isn’t checking whether your box has rounded corners and a nice paint job. It’s testing whether your equipment survives the exact failure modes that happen in real-world PV systems.

Here’s what a combiner box goes through to earn that UL 1741 listing:

DC arc fault testing: Can the breakers interrupt an arc at full string voltage under maximum current? They test this hundreds of times. Your AC panel’s breakers? Never tested for DC arcing. Zero times.

Short-circuit current testing: What happens when two strings accidentally short together, dumping 90 amps through a bus bar rated for 20? The test exposes every connection point to fault currents 10-20× normal operating current. Everything that’s going to melt, melts in the lab instead of on your roof.

Temperature cycling: Rooftop combiner boxes swing from -40°F winter nights to 140°F summer days under direct sun. UL cycles the equipment through these extremes while fully loaded. Connections that would loosen after three years of thermal expansion? They fail in the test chamber.

පාරිසරික ආරක්ෂාව: That NEMA 3R rating isn’t decorative. It means the box survives horizontal rain, doesn’t accumulate ice that blocks ventilation, and keeps dust off the bus bars even when mounted in a dusty industrial environment. Your garage subpanel is NEMA 1—designed for nice, clean indoor use at room temperature.

The real cost of that $240 upgrade isn’t the materials. A DC-rated breaker costs maybe $30 instead of $12 for an AC breaker. The metal enclosure costs another $50. The rest? It’s the engineering hours spent making sure those components work together reliably under worst-case conditions, and the testing to prove it.

When you skip UL 1741, you’re not just missing a sticker. You’re missing 10,000 hours of destructive testing that identified every single failure mode your roof-mounted box is going to face over the next 20 years. You’re beta-testing those failure modes yourself.

In real-time.

On your roof.

4 Non-Negotiable Requirements for a Safe DIY Solar Combiner Box

Let’s be clear: building your own solar combiner box is technically possible. But it’s only worth doing if you meet every single one of these requirements. Skip even one, and you’d be better off buying the pre-made box.

Requirement #1: DC-Rated Components with Proper Voltage Ratings

Your shopping list for a DIY solar combiner box starts here: every breaker, ෆියුස්, bus bar, පර්යන්ත කොටස, and disconnect inside that box must be explicitly rated for DC voltage සහ for at least 600 volts DC.

Not 600VAC. Not “suitable for solar.” Not “probably fine.” The datasheet must state: “600VDC” in plain text.

Why 600V when your strings are only 93.4V? Two reasons. First, NEC Article 690.7 requires voltage calculations based on the coldest expected temperature in your location. Solar panels produce higher voltage when cold—up to 10-15% higher than nameplate Voc depending on your climate zone. Your 46.7V panels might hit 53V each on a January morning. Two in series? 106 volts per string.

Second, you need safety margin for transient voltage spikes during cloud-edge effects (when sunlight intensity changes rapidly) and for equipment degradation over time. Industry standard: if your maximum system voltage is under 150VDC, use 600VDC-rated components. It’s not overkill; it’s the minimum for 25-year service life.

Where to source DC-rated components:

- DC breakers: Manufacturers like ABB, Eaton, Mersen, and Littelfuse make DC-rated molded case circuit breakers (MCCBs). Expect to pay $35-60 per breaker vs $12-18 for equivalent AC breakers. Check for “UL 489 supplement” DC rating or “IEC 60947-2 DC” marking.

- ෆියුස්: Ferraz Shawmut, Mersen, and Littelfuse offer PV-rated fuses with 600VDC to 1000VDC ratings. Use 15A fuses for standard 350W panels (calculated as Isc × 1.56 per NEC 690.8). Cost: $8-15 per fuse plus $25-40 per fuse holder.

- Bus bars: Copper or aluminum rated for 90°C minimum. Many AC-rated bus bars work fine, but verify the material spec handles DC current density (1.5-2.0 A/mm² for copper).

Pro-Tip #1: That “48V” marking on AC equipment? It refers to your battery voltage, not your panel string voltage. Your 48V battery system has 93.4V strings that need proper 600VDC-rated DC equipment.

Requirement #2: UL 1741-Listed Enclosure or Equivalent Protection

The metal box itself matters more than you think when building a DIY solar combiner box.

For rooftop installation, you need at minimum a NEMA 3R (rain-tight) or IP54 යනු IP54 හි ඇති බහුමාධ්ය අනුවාදයයි. (dust and splash protected) rated enclosure. NEMA 1 indoor panels are not suitable. The enclosure must:

Handle thermal cycling: Rooftop temperatures swing 80-100°F daily. The enclosure needs gaskets that maintain their seal, knockouts that don’t crack from expansion/contraction, and paint that doesn’t flake off and contaminate electrical connections.

Provide adequate ventilation: DC breakers generate heat when carrying current. Without proper ventilation, internal temperatures can exceed component ratings even when the ambient temperature is acceptable. Look for enclosures with ventilation calculated for at least 30% more thermal load than your maximum string current.

Include proper grounding provisions: Your enclosure needs dedicated grounding bus bars with mechanical lugs (not spring clips) rated for #6 AWG copper minimum. Every metal surface inside the box must be bonded to ground. This isn’t optional—NEC 690.43 requires it.

Cost reality check: A proper NEMA 3R enclosure sized for 5-6 strings (approximately 12″ × 16″ × 6″) runs $80-150. A weatherproof outdoor-rated enclosure with the right knockouts, bus bars, and mounting hardware? $120-200. That’s 50-60% of your total DIY combiner box cost right there.

If you’re thinking “I’ll just use the AC panel and add a weatherproof cover,” stop. Those covers are designed to keep rain off the switches during momentary use—not provide continuous NEMA 3R protection for equipment that lives outdoors 24/7 for 25 years.

Requirement #3: Arc Fault Protection (NEC 690.11 Compliance)

Here’s where most DIY solar combiner box builds fail code inspection.

NEC 690.11 mandates arc fault circuit interrupters (AFCI) for any PV system with DC circuits operating at 80 volts or higher. Your 93.4V strings? You’re 17% over the threshold. AFCI is non-negotiable.

What AFCI actually does: It monitors the electrical signature of current flowing through the DC circuits and detects the specific noise pattern of an arc fault—the chaotic, high-frequency signal that appears when current jumps across a gap. When detected, it immediately interrupts the circuit before the arc can ignite nearby materials.

Remember The Arc That Won’t Die? AFCI is specifically designed to kill it.

Your two options:

Option 1 – Inverter with integrated AFCI: Most modern string inverters (SMA, SolarEdge, Fronius, etc.) have built-in arc fault detection per UL 1741. If your inverter has this, you don’t need separate AFCI in your DIY combiner box. Verify this by checking your inverter’s spec sheet for “UL 1741 AFCI compliant” or “NEC 690.11 arc fault protection.”

Option 2 – Standalone AFCI device: If your inverter doesn’t include AFCI, you need a listed arc fault detector installed in your combiner box or within 6 feet of it. These cost $200-400 and require additional wiring. Brands include Sensata, Eaton, and Mersen. This alone might make your DIY combiner box more expensive than buying a pre-made one.

Exception: If your DC wiring runs in metal conduit or metal-clad cable, and never exits that metal raceway between the panels and the inverter, you can skip AFCI. But realistically? Rooftop installations use exposed PV wire with MC4 connectors, which means AFCI is required.

Pro-Tip #2: DC arcs don’t die when you flip the switch—they keep burning at 35,000°F until physically suppressed. AFCI is how you suppress them before they start fires.

Requirement #4: Proper Labeling and Documentation (NEC 690.7, 690.15)

Code inspectors will red-tag your DIY solar combiner box installation for missing labels faster than for questionable component choices.

Required labels on your DIY combiner box:

1. Maximum DC voltage label (NEC 690.7):

MAXIMUM DC VOLTAGE: 106V (Based on 2× 46.7V panels at -10°C ambient) COMPLIES WITH NEC 690.7(D)

This label must be placed on the combiner box exterior and visible without opening the enclosure.

2. DC combiner identification (NEC 690.15):

WARNING: DC COMBINER BOX MULTIPLE DC VOLTAGE SOURCES DO NOT DISCONNECT UNDER LOAD

3. Conductor identification (NEC 690.31):

Every incoming string must be labeled with its source location:

- “STRING 1 – ARRAY NORTH”

- “STRING 2 – ARRAY NORTH”

- “STRING 3 – ARRAY SOUTH”

- etc.

4. Grounding electrode conductor label (if applicable):

If your grounding conductor terminates in the combiner box, label it per NEC 690.47.

Use outdoor-rated label stock (3M or Brady polyester labels with UV-resistant ink). Printed paper labels in weatherproof sleeves won’t pass inspection—they degrade too quickly.

Documentation you need:

- One-line diagram showing string configuration and voltages

- Component datasheets proving DC ratings

- Calculation showing NEC 690.7 max voltage

- NEC 690.8 current calculations

Keep copies inside the combiner box in a weatherproof document pouch. Inspectors may request them.

The Real Math: $300 Combiner Box vs. The Alternative

Let’s talk money. Real money.

Your compliant DIY solar combiner box parts list:

- NEMA 3R enclosure with breaker mounts: $120

- Five DC-rated 15A breakers at $45 each: $225

- DC-rated bus bars and terminals: $60

- Hardware, labels, wire, connectors: $40

- Total: $445

Wait. The pre-made UL 1741-listed combiner box costs $320. Your “DIY savings”? You’re losing $125 plus 6-8 hours of assembly and wiring time.

But that’s assuming you don’t need separate AFCI. Add that $300 device? Now you’re at $745 vs. $320 for the pre-made box that includes integrated AFCI.

The math doesn’t work for most DIY solar combiner box projects. Unless you’re building for 10+ strings where pre-made boxes get expensive (over $800), or you need a custom configuration that’s not available off-the-shelf, DIY combiner boxes are often more expensive than buying properly certified equipment.

Here’s the math that really matters:

Cost of one electrical fire: $50,000-$250,000 in structural damage, depending on when the fire department arrives.

Cost of homeowner’s insurance premium increase after an electrical fire: 20-40% increase for 3-5 years = $1,200-$3,000 additional cost.

Cost of insurance claim denial because you used non-listed equipment: 100% of the damages = whatever the fire costs.

Cost of permitting issues when you try to sell your house: Delays, re-inspections, potential contractor costs to bring to code = $2,000-$8,000.

That $240 price difference? It’s not buying a fancy label. It’s buying peace of mind that every single component was torture-tested for the exact failure modes that happen on rooftops. It’s buying insurance-compliant equipment that won’t void your policy. It’s buying inspector-approved hardware that won’t delay your permit by three months.

Pro-Tip #3: The real DIY skill isn’t figuring out how to build everything yourself—it’s knowing which corners you can cut and which ones cut back. Combiner boxes cut back.

When DIY Actually Makes Sense

Don’t mistake this article for “never build anything yourself.” Solar installations have plenty of legitimate DIY opportunities:

Smart DIY projects:

- Racking and mounting: You can absolutely design and install your own panel mounting system. It’s mechanical, it’s verifiable, and there’s no Arc That Won’t Die trying to kill you if you get something wrong.

- Conduit runs: Running EMT or PVC conduit from your combiner box to your inverter? Great DIY project. Just follow NEC conduit fill calculations.

- System monitoring: Adding performance monitoring, data logging, even IoT integrations to track your system? Go wild. Worst case is you lose some data.

Reckless DIY projects:

- Combiner boxes (as we’ve discussed)

- DC disconnects between combiner and inverter (same issues: DC arc interruption, voltage ratings)

- Inverter installation (complex electrical connections, AC/DC integration points)

- Service panel interconnections (requires licensed electrician in most jurisdictions)

The pattern? If it’s carrying high-voltage DC or connecting to your main electrical service, hire professionals or buy listed equipment. If it’s structural, mechanical, or low-voltage monitoring, DIY away.

The Bottom Line: Build Smart, Not Just Cheap

If you made it this far, you’re already ahead of 90% of DIY solar installers. You’re asking the right questions.

Here’s what you’ve learned:

The Arc That Won’t Die: DC arcs don’t self-extinguish like AC arcs. They burn at 35,000°F until physically suppressed. AC equipment isn’t designed for this.

The 48V Confusion: Your battery voltage isn’t your string voltage. That 48V system has 93.4V strings that need 600VDC-rated equipment, not repurposed AC panels.

The Voltage Rating Trap: AC voltage ratings don’t translate to DC. A 240VAC breaker might only be safe to 48VDC. Your 93.4V strings exceed most AC equipment’s DC capability.

The Compliance Cost: Building a code-compliant DIY solar combiner box costs $445-$745. Buying a pre-made UL 1741-listed box? $320. The math doesn’t support DIY unless you need custom configurations.

Can you technically build your own combiner box? Yes. With the right components, proper enclosures, AFCI protection, and correct labeling, it’s possible.

Should you? Probably not. The cost savings evaporate once you price out DC-rated components and AFCI. The time investment (8-10 hours for first build, 4-6 for subsequent ones) rarely justifies the marginal savings. And the liability if something goes wrong—that insurance claim denial, that permit rejection, that inspector’s red tag—wipes out any financial benefit.

The real DIY move? Know when to build and when to buy.

Save your DIY energy for the racking, the monitoring systems, the conduit runs, the parts of solar installations where your effort actually multiplies your money instead of just increasing your risk.

And that $60 Square D panel in your garage? Use it where it belongs—on an AC circuit, where the zero-crossing does the heavy lifting and arcs die on their own like they’re supposed to.

Because in solar PV, the most expensive mistake isn’t the one that costs you $300 up front. It’s the one that saves you $240 today and costs you $50,000 six months from now when The Arc That Won’t Die finds something flammable.

Ready to do your solar installation right? Check out our complete line of UL 1741-listed combiner boxes and DC-rated protection equipment designed specifically for residential and commercial PV systems. We’ve already done the engineering and testing—you get reliable equipment at prices that make DIY look expensive.