Introduction: When IP Rating Matters

A solar contractor in Arizona learned an expensive lesson last summer. Three months after commissioning a 500kW commercial rooftop array, the owner called with a problem: half the DC isolator switches had corroded contacts and wouldn’t open. The contractor had specified IP40-rated indoor switches enclosed in NEMA 3R boxes, assuming the external enclosure would provide adequate protection. But desert dust infiltrated through cable entries, and monsoon moisture condensed inside. The result: $12,000 in switch replacements, two weeks of downtime, and a damaged reputation.

The isolator’s IP (Ingress Protection) rating isn’t just a catalog specification—it’s the primary determinant of how long your switch survives in its installation environment. Choose too low, and you’ll face premature failures, safety hazards, and costly field replacements. Specify too high, and you’re paying for protection you don’t need.

This guide clarifies the technical differences between indoor and outdoor isolator switch requirements, explains how to interpret IP ratings under IEC 60529, and provides a practical framework for matching protection level to installation environment. Whether you’re specifying DC isolators for a solar farm, AC switches for industrial motor control, or designing a distribution panel, understanding IP rating requirements will save you from the Arizona contractor’s mistake.

Understanding IP Rating Standards: IEC 60529 Decoded

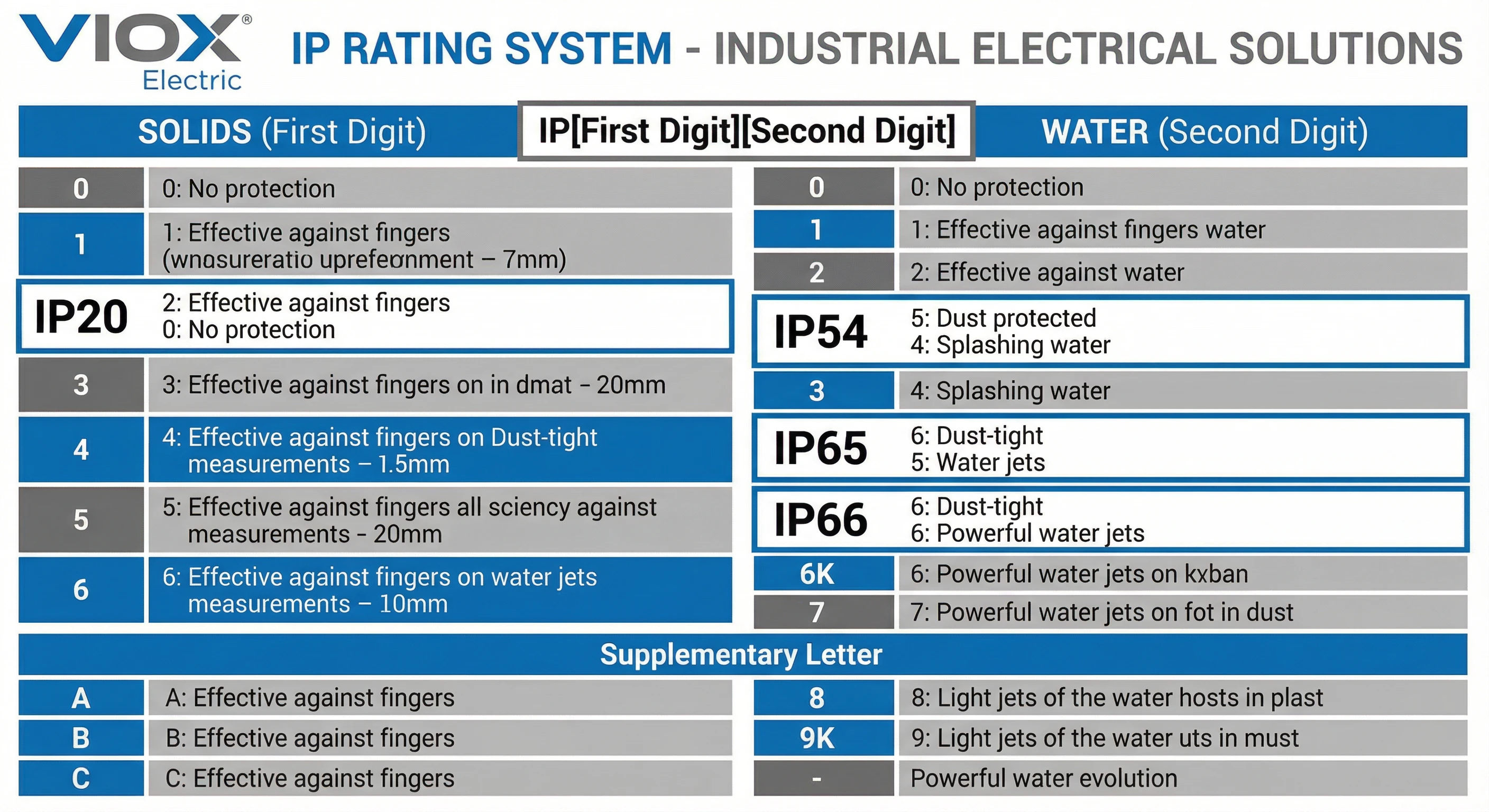

The IP code uses two digits to communicate protection performance. It’s simpler than it looks once you understand the structure.

IP Rating Format: IP [First Digit] [Second Digit]

The first digit (0-6) indicates protection against solid object ingress:

| First Digit | Solid Protection Level | Practical Meaning |

| 0 | Fără protecție | Open contacts, internal mounting only |

| 1 | >50mm (hand-sized objects) | Prevents accidental hand contact |

| 2 | >12.5mm (finger-sized) | Finger-safe, standard for accessible indoor switches |

| 3 | >2.5mm (tool entry) | Prevents tool or wire probe entry |

| 4 | >1mm (wire and small debris) | Protects against most solid foreign objects |

| 5 | Dust-protected (limited ingress) | No harmful dust accumulation |

| 6 | Dust-tight (zero ingress) | Hermetically sealed against dust |

The second digit (0-8) indicates protection against water ingress:

| Second Digit | Water Protection Level | Test Condition |

| 0 | Fără protecție | Dry locations only |

| 1 | Dripping water (vertical) | Light condensation |

| 2 | Dripping water (15° tilt) | Slight angle exposure |

| 3 | Spraying water (60° from vertical) | Rain at an angle |

| 4 | Splashing water (any direction) | Rain, splashing from any angle |

| 5 | Water jets (6.3mm nozzle, 12.5 l/m) | Low-pressure cleaning, heavy rain |

| 6 | Powerful water jets (12.5mm, 100+) | High-pressure washdown, rough sea conditions |

| 7 | Temporary immersion (1m, 30 min) | Accidental flooding |

| 8 | Continuous immersion (depth agreed) | Submersible applications (rare for isolator switches) |

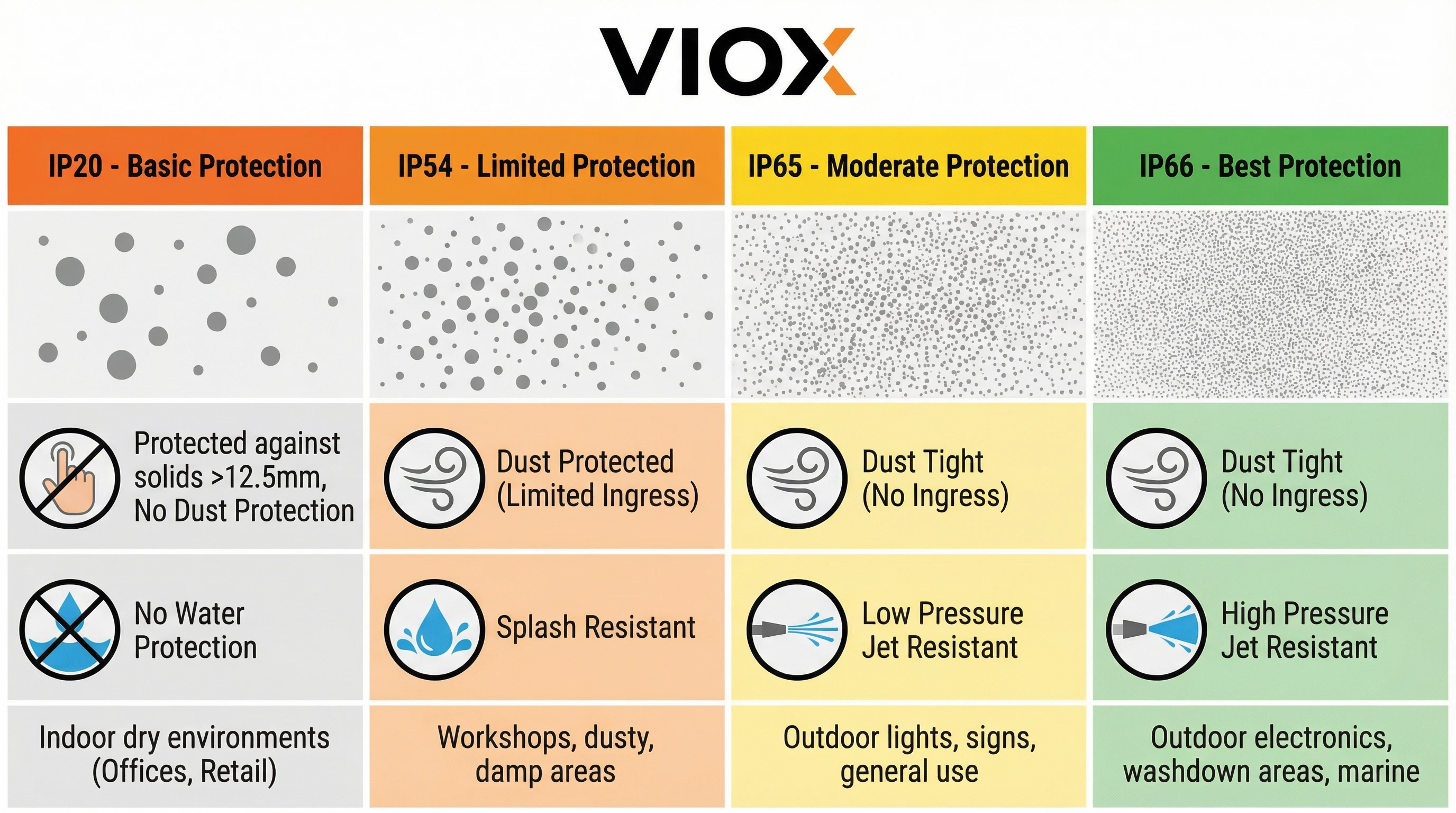

For isolator switches, the most common ratings you’ll encounter are IP20, IP40, IP54, IP65, and IP66. Let’s decode a practical example:

IP66 = Dust-tight (6) + Protected against powerful water jets (6)

This rating means the switch is hermetically sealed against dust and can withstand direct high-pressure water spray from any angle—ideal for outdoor solar arrays, industrial washdown zones, and coastal installations.

IP20 = Finger-safe (2) + No water protection (0)

Basic protection against accidental contact, suitable only for dry indoor locations like residential distribution panels or climate-controlled electrical rooms.

One critical point: IP ratings test ingress protection under laboratory conditions. They don’t address corrosion resistance, UV degradation, thermal cycling, or condensation—all of which matter in real installations. A coastal site needs IP66 plus corrosion-resistant materials and coatings. A desert rooftop needs IP65/66 plus UV-stabilized plastics. The IP rating is your baseline; environmental factors determine what else you need.

Indoor Isolator Switches: Protection Requirements

Indoor installations benefit from controlled environmental conditions. No direct rain exposure, limited dust, and relatively stable temperatures mean you can specify lower IP ratings without compromising reliability.

Minimum Indoor Requirements: IP20

IP20 is the baseline for accessible isolator switches in dry indoor locations. The “2” provides finger-safe protection—you can’t accidentally touch live parts—while the “0” indicates no water protection is provided. This rating works for:

- Residential distribution panels in dry utility rooms

- Commercial electrical closets with climate control

- Industrial control rooms with HVAC and filtered air

- Behind locked panel doors away from cleaning activities

IP20 switches cost less and offer easier cable entry, but they’re vulnerable to any moisture or dust exposure. If your panel is in a basement prone to seasonal dampness, or near a mechanical room that gets condensation, step up to IP30 or IP40.

Upgraded Indoor: IP30-IP40

IP30 and IP40 add meaningful protection against small debris and dust while maintaining zero water resistance:

- IP30: Prevents entry of objects >2.5mm (small tools, wire clippings). Common in commercial distribution boards where maintenance staff use tools nearby.

- IP40: Protects against >1mm objects (wire strands, small debris). Preferred for light industrial panels, warehouses, and areas with moderate dust but no water exposure.

These ratings add minimal cost—5-10% over IP20—but significantly reduce the risk of foreign object entry during maintenance work. Many panel builders standardize on IP40 for all commercial indoor applications simply to eliminate variability.

When Indoor Isn’t Really “Indoor”

Watch for edge cases where nominally indoor spaces have outdoor-like conditions:

- Parking garages: Road salt spray and vehicle exhaust require IP54 minimum

- Kitchens and laundries: Steam and cleaning spray demand IP54-IP65

- Pool equipment rooms: High humidity and splashing need IP65

- Unconditioned warehouses: Temperature swings cause condensation; use IP40 minimum, consider IP54

- Agricultural buildings: Dust and wash-down conditions require outdoor ratings

If there’s any possibility of direct water exposure—even from a hose during cleaning—specify an outdoor-rated switch.

Outdoor Isolator Switches: Environmental Challenges

Outdoor installations face continuous environmental assault: rain, snow, dust, UV radiation, temperature extremes, and salt spray in coastal areas. IP ratings must match the worst-case conditions your switch will encounter over its 20-25 year design life.

Minimum Outdoor Baseline: IP54

IP54 is the entry point for outdoor isolator switches in relatively benign climates:

- IP5X (dust-protected): Allows limited dust ingress that won’t interfere with operation or compromise safety. Suitable for areas with moderate airborne dust but not heavy industrial or desert environments.

- IPX4 (splash-proof): Protects against rain splashing from any direction. Adequate for locations with normal rainfall but not high-wind-driven rain or direct water spray.

IP54 works for:

- Covered outdoor installations (under eaves, canopies)

- Mild climates with gentle rainfall patterns

- Locations with minimal windborne dust

- Temporary outdoor installations with planned short service life

But IP54 has clear limits. It won’t survive high-pressure cleaning, heavy dust environments, or sustained exposure to wind-driven rain. Most solar PV and industrial applications need higher protection.

Recommended Outdoor: IP65

IP65 provides robust protection for most outdoor applications:

- IP6X (dust-tight): Hermetically sealed; zero dust ingress

- IPX5 (jet-proof): Withstands low-pressure water jets (12.5 liters/min from 6.3mm nozzle)

This rating handles:

- Rooftop solar PV installations (the most common DC isolator application)

- Ground-mount solar arrays

- Outdoor industrial equipment disconnects

- Building exterior installations

- Sites with dusty conditions but not extreme washdown

IP65 offers the sweet spot for solar contractors: comprehensive dust and water protection at reasonable cost. For standard PV projects in most climates, IP65 is the specification to beat.

Maximum Outdoor: IP66

IP66 raises water protection to the highest practical level for non-submersible applications:

- IP6X (dust-tight): Same hermetic sealing as IP65

- IPX6 (powerful jet-proof): Survives powerful water jets (100+ liters/min from 12.5mm nozzle)

Specify IP66 when your installation faces:

- High-pressure washdown zones in food processing, pharmaceuticals, or chemical plants

- Coastal installations with salt spray and storm exposure

- Desert environments with extreme dust and monsoon rain

- Sites subject to regular high-pressure cleaning

- Locations where water ingress could create safety hazards (high-voltage DC combiner boxes)

The cost premium over IP65 is typically 10-15%, but the added durability justifies it for harsh service. VIOX’s VOPV series DC isolators carry IP66 as standard because solar installations increasingly face extreme weather events and need maximum protection.

Environmental Factors Beyond IP Rating

Remember that IP ratings don’t cover several critical outdoor degradation mechanisms:

- UV exposure: Plastics degrade and embrittle. Specify UV-stabilized materials and check for outdoor ratings beyond IP.

- Ciclul de temperatură: Daily and seasonal swings cause expansion/contraction and condensation. Mount vertically, use drainage/ventilation features, and ensure gaskets remain compliant across temperature range.

- Salt spray: Coastal sites need corrosion-resistant hardware (stainless steel fasteners, coated terminals) beyond the IP rating.

- Ice formation: Freezing water can compromise seals. In sub-zero climates, verify the isolator’s rated temperature range and consider heated enclosures for critical applications.

IP Rating Comparison: Indoor vs Outdoor Applications

This table summarizes typical IP rating selections by environment and application:

| Clasificare IP | Protecție împotriva prafului | Water Protection | Aplicații Tipice | Mediul înconjurător | Approx. Cost Index |

| IP20 | Finger-safe (>12.5mm) | Nici unul | Residential panels, commercial electrical rooms, control panels | Dry indoor, climate-controlled | 1.0x (baseline) |

| IP30 | Tool-proof (>2.5mm) | Nici unul | Commercial distribution boards, industrial control rooms | Dry indoor, moderate access | 1.05x |

| IP40 | Wire-proof (>1mm) | Nici unul | Light industrial panels, warehouses, unconditioned indoor | Indoor, moderate dust | 1.10x |

| IP54 | Dust-protected | Splash-proof (any dir.) | Covered outdoor, mild climates, semi-exposed installations | Outdoor, minimal harsh exposure | 1.30x |

| IP65 | Dust-tight | Jet-proof (low press.) | Rooftop solar PV, ground-mount arrays, outdoor equipment disconnects | Outdoor, standard exposure | 1.50x |

| IP66 | Dust-tight | Jet-proof (high press.) | Washdown zones, coastal/marine, extreme climates, high-voltage DC boxes | Outdoor, harsh/critical exposure | 1.65x |

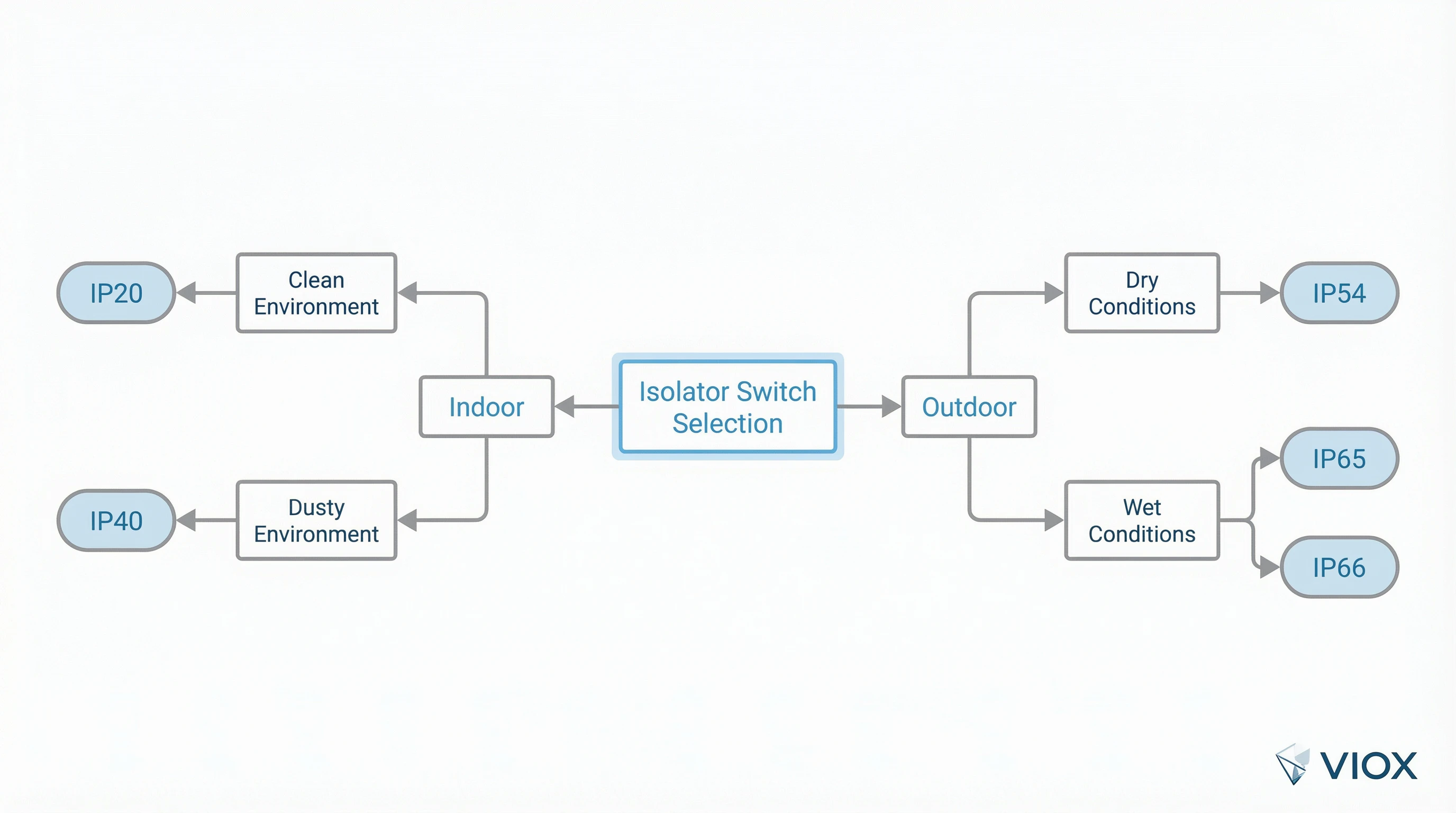

Key Selection Rules:

- Start with environment: Indoors = IP20-IP40; Outdoors = IP54-IP66

- Consider worst-case exposure: Specify for the harshest condition over the equipment’s life

- Account for maintenance: Will the area be hosed down or pressure washed? Step up accordingly

- Factor in criticality: High-voltage DC (>600V) or safety-critical isolation? Use IP65/66 even if environment might permit IP54

- Check external enclosures: An IP20 switch in an IP65 enclosure achieves IP65 system protection—but only if cable entries maintain the seal

Environmental Factors Affecting IP Rating Selection

Beyond the basic indoor/outdoor distinction, specific environmental factors drive IP rating decisions.

Dust and Particulate Exposure

Dust isn’t just a nuisance—it’s a reliability killer. Conductive dust (metal shavings, carbon) can bridge air gaps and cause tracking. Non-conductive dust absorbs moisture and becomes conductive over time. High-volume dust clogs cooling vents and accelerates wear on mechanical parts.

Environment-specific dust considerations:

- Woodworking shops: Fine sawdust infiltrates everything; IP54 minimum, IP65 preferred

- Metal fabrication: Conductive metal dust requires IP54+ to prevent shorts

- Mining and quarrying: Heavy dust loads demand IP66 dust-tight protection

- Agricultură: Grain dust, fertilizer, and soil particles need IP54-IP65

- Desert climates: Fine sand penetrates even small gaps; specify IP65/66

If you can see airborne dust accumulating on surfaces within a week, you need IP5X or IP6X protection.

Water and Moisture Exposure

Water kills electrical equipment through multiple mechanisms: direct shorts, corrosion, insulation degradation, and moisture-accelerated tracking. Match the second IP digit to your water exposure scenario:

- IPX0 (no protection): Absolutely dry indoor only

- IPX4 (splash-proof): Normal rain, incidental splashing

- IPX5 (low-pressure jets): Heavy rain, hose-down at distance, light cleaning spray

- IPX6 (powerful jets): Direct high-pressure washdown, storm-driven rain, rough sea spray

Consider these moisture sources beyond direct rain:

- Condensation: Temperature cycling in high-humidity areas creates internal condensation even in sealed enclosures. Mount vertically, use drain holes or breathers, and consider internal heating

- Fog and mist: Coastal fog or industrial mist can exceed splash-proof ratings over time; use IP65+

- Snow and ice: Accumulated snow melting during temperature swings creates sustained water exposure; IP65 minimum

- Groundwater and flooding: Sites with flood risk need IP67 (temporary immersion) or elevated mounting

UV Radiation and Temperature Extremes

IP ratings don’t test these factors, but they’re critical for outdoor longevity:

- UV degradation: Most plastics become brittle after 5-10 years of direct sun exposure unless UV-stabilized. Check for outdoor ratings beyond IP (UL Type ratings, IK impact codes after UV exposure)

- Intervalul de temperatură: Standard isolators typically rate -25°C to +70°C. Desert rooftops exceed this in summer; arctic sites drop below it in winter. Verify your switch’s temperature range matches site extremes

- Thermal cycling stress: Daily swings of 40-50°C cause expansion/contraction that fatigues seals and loosens connections. Coastal and desert sites face the worst cycling

Atmosfere corozive

Salt spray, industrial chemicals, and agricultural environments attack metal components and terminals:

- Coastal sites (<5km from ocean): Require stainless steel or coated fasteners, corrosion-resistant terminals, and conformal coating on PCBs beyond IP66

- Chemical plants: May need IP66 plus materials rated for specific chemical exposure (acids, solvents, caustics)

- Agricultural: Fertilizers, pesticides, and manure gases accelerate corrosion; use IP65+ with corrosion-resistant materials

IP ratings test water ingress but don’t address salt content or chemical corrosivity. Specify corrosion-resistant hardware separately.

Common Applications and Recommended IP Ratings

Here’s practical guidance for the most common isolator switch applications:

Sisteme solare fotovoltaice

- Rooftop residential (string inverters): IP65 minimum for DC isolators on roof or exterior wall. VIOX VOPV series with IP66 provides added margin for severe weather

- Rooftop commercial (central inverters): IP66 for DC combiner boxes and array disconnects due to higher voltage (up to 1500V) and extended 25+ year service life

- Ground-mount utility-scale: IP66 standard; sites with extreme dust (desert) or salt spray (coastal) need additional corrosion-resistant coatings

- AC disconnect (inverter-side): IP54 minimum if inverter is in weather-protected enclosure; IP65 if fully exposed

Controlul motoarelor industriale

- Indoor motor control centers: IP20-IP30 for switches within enclosed panels; IP40 if panel is in dusty factory floor

- Outdoor motors and pumps: IP66 for direct weather exposure; IP54 if under roof with open sides

- Washdown areas (food/pharma): IP66 mandatory; verify gaskets and seals are food-grade rated

- Locații periculoase: IP rating alone insufficient—must meet Division/Zone requirements with appropriate T-rating

Residential and Commercial Buildings

- Residential main disconnect (meter-adjacent): IP54 minimum for exterior mounting; IP65 for full weather exposure

- HVAC equipment disconnect: IP54-IP65 depending on exposure (rooftop = IP65)

- Piscină/spa echipamente: IP65 minimum due to splashing and high humidity; IP66 preferred

- Parking garage distribution: IP54 due to vehicle spray, exhaust, and seasonal road salt

Sisteme de stocare a energiei în baterii

- Indoor battery rooms: IP20 adequate if room is climate-controlled and ventilated

- Outdoor battery enclosures: IP65 minimum; IP66 for coastal or extreme climates

- Integrated outdoor battery systems: Match enclosure rating; typically IP65-IP66

Telecomunicații și centre de date

- Indoor telecom/data center: IP20 standard; clean, climate-controlled environment

- Outdoor cell sites: IP65 minimum; IP66 for mountaintop or coastal sites with harsh weather

Installation Best Practices for Different Environments

Achieving the rated IP protection requires proper installation. Even an IP66-rated switch will fail if cable entries compromise the seal.

Cable Entry: The Weak Link

Most IP rating failures trace to improper cable entry. Glands, grommets, and conduit fittings must match or exceed the enclosure’s IP rating:

- Use rated cable glands: Specify IP-rated cable glands with sealing inserts matched to cable diameter. Undersized or oversized inserts leak

- Follow torque specs: Over-tightening crushes seals; under-tightening allows gaps. Use a torque wrench for critical installations

- Seal unused entries: Every unused knockout, gland hole, or conduit entry needs a rated blanking plug with gasket

- Orient downward where possible: Top-entry invites water pooling around glands; side or bottom entry with drip loops is better

- Maintain conduit seals: Rigid conduit connections need sealing locknuts or compression fittings; flexible conduit needs IP-rated strain-relief glands

Mounting and Orientation

How you mount the isolator affects water drainage and exposure:

- Vertical mounting preferred: Prevents water pooling on top surfaces

- Slight forward tilt: If wall-mounting, tilt top forward 5-10° so rain runs off face

- Avoid upward-facing entries: Cable glands should enter from sides or bottom

- Clear mounting surface: Rough or uneven walls prevent gasket seal; use backing plate or shim to flat surface

- Drip loops: Run cables down from gland entry then back up to prevent water following cable into enclosure

Gasket and Seal Maintenance

IP protection degrades over time as gaskets age:

- Inspect annually: Check gaskets for compression set, cracks, or hardening

- Replace during service: If you open the enclosure for maintenance, install new gaskets

- Clean sealing surfaces: Dust, oil, or paint on gasket surfaces breaks the seal

- Don’t over-service: Each open/close cycle stresses the gasket; minimize unnecessary access

Environmental-Specific Practices

- Coastal sites: Rinse enclosures quarterly with fresh water to remove salt buildup before it corrodes seals

- Desert sites: Check for sand infiltration around glands; may need additional external shrouding

- Sub-zero locations: Verify gasket material remains pliable at minimum temperature; silicone performs better than EPDM below -40°C

- High-vibration sites: Use thread-locking compound on fasteners; vibration loosens screws and creates gaps

Cost vs Protection: Making the Right Investment

IP ratings directly impact product cost and installation labor. Understanding the trade-offs helps you specify appropriately without over-engineering.

Material Cost Premiums

Relative to IP20 baseline:

- IP30-IP40: +5-10% (better gaskets, tighter tolerances)

- IP54: +30% (sealed enclosure, gasketed cover, rated cable entries)

- IP65: +50% (comprehensive sealing system, multi-point gaskets, precision machining)

- IP66: +65% (heavy-duty gaskets, reinforced seals, high-pressure test certification)

For a typical 4-pole 63A DC isolator, this translates to:

- IP20: $45-60

- IP40: $50-65

- IP54: $70-85

- IP65: $90-110

- IP66: $100-120 (VIOX VOPV series pricing)

For a single switch, the premium seems modest. For a 1MW solar project with 40 string disconnects, it’s the difference between $2,400 (IP54) and $4,000 (IP66)—but that $1,600 investment prevents $50,000+ in replacement costs and downtime.

Installation Cost Impact

Higher IP ratings require more careful installation:

- IP20-IP40: Standard installation, simple cable entry, 15-20 min per switch

- IP54-IP66: Rated cable glands required, torque specs critical, gasket inspection, 25-35 min per switch

For 40 switches, the extra labor adds $800-1,200 to project cost. But improper IP20 installation leading to field failures costs 10x more in service calls and replacements.

Failure Cost Analysis

Consider total cost of ownership over 20 years:

Scenario: Rooftop Solar DC Isolator (under-specified IP40 vs. proper IP66)

- Initial cost difference: $50 (IP66 costs $50 more than IP40)

- Probability of premature failure: 60% over 20 years for IP40 in outdoor exposure vs. 5% for IP66

- Average replacement cost: $800 (truck roll, labor, parts, system downtime)

- Expected 20-year cost:

- IP40: $60 initial + ($800 × 0.60) = $540

- IP66: $110 initial + ($800 × 0.05) = $150

The “cheaper” IP40 switch costs 3.6x more over its life.

When to Upgrade vs. When to Save

Upgrade to higher IP when:

- Equipment operates outdoors or in harsh indoor environments

- Replacement access is difficult (rooftops, remote sites)

- Failure creates safety hazards (high-voltage DC)

- Long service life expected (>15 years)

- Warranty or liability concerns exist

Save with lower IP when:

- Truly benign indoor environment (climate-controlled electrical rooms)

- Easy access for maintenance and replacement

- Short service life planned (<5 years)

- Secondary protection exists (isolator inside IP65 enclosure)

For most outdoor isolator applications—especially solar PV—IP65 is the economic optimum. IP66 adds margin for critical or extreme installations at modest incremental cost.

VIOX IP-Rated Isolator Solutions

VIOX Electric designs isolator switches with environmental protection matched to real-world applications. Our VOPV series DC isolators set the industry standard for solar PV and battery storage installations.

VOPV Series: IP66 Protection Standard

- IP66 rating across full range: 2-pole through 4-pole configurations, 32A to 125A ratings

- 1500V DC capability: Meets IEC 60947-3:2025 for next-generation high-voltage PV systems

- UV-stabilized housing: UL-rated for outdoor exposure, tested to 2000+ hours UV-A/UV-B

- Stainless steel hardware: Corrosion-resistant fasteners standard for coastal and marine applications

- IP66-rated cable glands included: Eliminates weak-link cable entry issues

- -40°C to +85°C operating range: Handles extreme climates from arctic to desert installations

VOS Series: Indoor AC Isolators

- IP20 and IP40 options: Match protection level to installation environment

- DIN rail or panel mount: Flexible integration for distribution boards and control panels

- IEC 60947-3 Type A (no-load switching): AC-21A utilization category

- Cost-optimized for indoor use: No over-specification for controlled environments

Custom IP Solutions

VIOX works with panel builders and OEMs to customize IP protection levels for specific applications. Our engineering team can specify:

- Upgraded gasket materials for chemical resistance

- Extended temperature range variants

- IP66 with additional NEMA 4X corrosion testing

- Integrated auxiliary contacts and status indication

Contact VIOX technical support to discuss your application requirements and select the optimal IP rating for your installation environment.

Conclusion: Matching Protection to Environment

IP ratings are your primary tool for matching isolator switch protection to installation environment. The two-digit code under IEC 60529 tells you exactly what dust and water exposure the device can withstand—but only if you specify correctly and install properly.

The decision framework is straightforward:

- Indoor, climate-controlled: IP20 baseline, IP40 for added debris protection

- Indoor, unconditioned or dusty: IP40 minimum

- Outdoor, benign climate: IP54 minimum

- Outdoor, standard exposure: IP65 recommended

- Outdoor, harsh or critical: IP66 standard

Don’t under-specify. The Arizona contractor’s $12,000 lesson demonstrates what happens when you assume an external enclosure compensates for an inadequate switch IP rating. Cable entries compromise seals, condensation forms inside enclosures, and dust infiltrates through the smallest gaps. Specify the switch itself to withstand the environment it will actually experience.

And don’t over-specify needlessly. IP66 costs 65% more than IP20. For a true indoor application in a clean electrical room, IP20 is technically and economically appropriate. Save the budget for where it matters—the outdoor, exposed, or harsh-environment installations where protection directly determines reliability.

Ultimately, proper IP rating selection prevents the failures, safety incidents, and costly replacements that under-specification inevitably causes. Match your isolator’s IP rating to your installation’s environment, follow manufacturer installation guidelines for cable entries and mounting, and you’ll achieve the 20-25 year service life the equipment was designed to deliver.

For technical support on IP rating selection for your specific application, contact VIOX Electric‘s application engineering team. We provide detailed environmental assessment and product recommendations to ensure your isolator switch specification meets both technical and economic requirements.