PNP and NPN proximity sensors, essential components in automation and control systems, differ primarily in their output configuration and wiring, with PNP sensors sourcing current and NPN sensors sinking current when activated.

PNP vs NPN Sensors

PNP and NPN sensors, also known as sourcing and sinking sensors respectively, are two distinct types of proximity sensors used in industrial applications. The key difference lies in their internal circuit design and transistor types. PNP sensors output a high-level signal when activated, connecting the signal terminal to the positive supply, while NPN sensors provide a low-level or ground signal upon activation. This fundamental distinction affects how these sensors interact with control systems and determines their compatibility with various input devices.

Output and Wiring Differences

The output and wiring configurations of PNP and NPN proximity sensors play a crucial role in their functionality and integration within control systems. PNP sensors, often referred to as “sourcing sensors,” provide a positive voltage output when activated. This means they source current from the positive supply to the load, making them ideal for applications where a positive signal is required to trigger an input device.

In contrast, NPN sensors, known as “sinking sensors,” operate by providing a ground signal when activated. These sensors sink current from the load to the negative supply, effectively completing the circuit by connecting the output to ground.

The wiring configurations for these sensor types differ accordingly:

- PNP sensors typically have three wires:

- Brown: Connected to the positive supply

- Blue: Connected to the negative supply

- Black: Output signal wire (switches to positive when activated)

- NPN sensors also use a three-wire configuration:

- Brown: Connected to the positive supply

- Blue: Connected to the negative supply

- Black: Output signal wire (switches to negative when activated)

This fundamental difference in output and wiring affects how these sensors interface with control devices. For instance, when connecting to a Programmable Logic Controller (PLC), the input card must be set to accommodate the specific sensor type. PNP sensors require the PLC input to be configured as a sinking input, while NPN sensors necessitate a sourcing input configuration.

Understanding these output and wiring differences is essential for engineers and technicians when designing and implementing automation systems, ensuring proper sensor selection and seamless integration with control devices.

Regional Usage Preferences

Regional preferences for PNP and NPN sensors vary significantly:

- North America predominantly uses PNP sensors due to their compatibility with many PLC inputs that expect a sourcing configuration.

- Asia and Europe, particularly in automotive applications, widely utilize NPN sensors where sinking connections are prevalent.

These regional preferences are driven by historical industrial practices and the compatibility of existing control systems, influencing the choice between sourcing (PNP) and sinking (NPN) sensor types in different parts of the world.

Control Systems Compatibility

The choice between PNP and NPN sensors is often dictated by the specific requirements of the control system in use. Systems designed for sinking inputs, common in many European PLCs, are better suited for NPN sensors. Conversely, control systems requiring sourcing inputs benefit from PNP sensors. This compatibility consideration is crucial for ensuring optimal performance and seamless integration within automation applications. When selecting a sensor type, engineers must carefully evaluate the input specifications of their control devices to maintain system integrity and functionality.

Impact of Sensor Choice on System Design

The choice between PNP and NPN proximity sensors significantly impacts overall system design in automation and control applications. PNP sensors, which source current, typically require less complex wiring and offer better noise immunity, making them preferable in electrically noisy environments. Conversely, NPN sensors, which sink current, are often more cost-effective and can be advantageous in systems with multiple sensors sharing a common positive supply.

When designing a system, engineers must consider:

- Power consumption: PNP sensors generally consume more power than NPN sensors.

- Wiring complexity: NPN sensors may require additional pull-up resistors in some applications.

- Compatibility with existing equipment: Ensure the chosen sensor type matches the input requirements of PLCs or other control devices.

- Safety considerations: In some cases, PNP sensors are preferred for their fail-safe characteristics in the event of a wiring fault.

Ultimately, the impact of sensor choice extends beyond mere signal output, influencing system reliability, maintenance requirements, and overall performance in industrial automation settings.

Three-Wire Sensor Connections

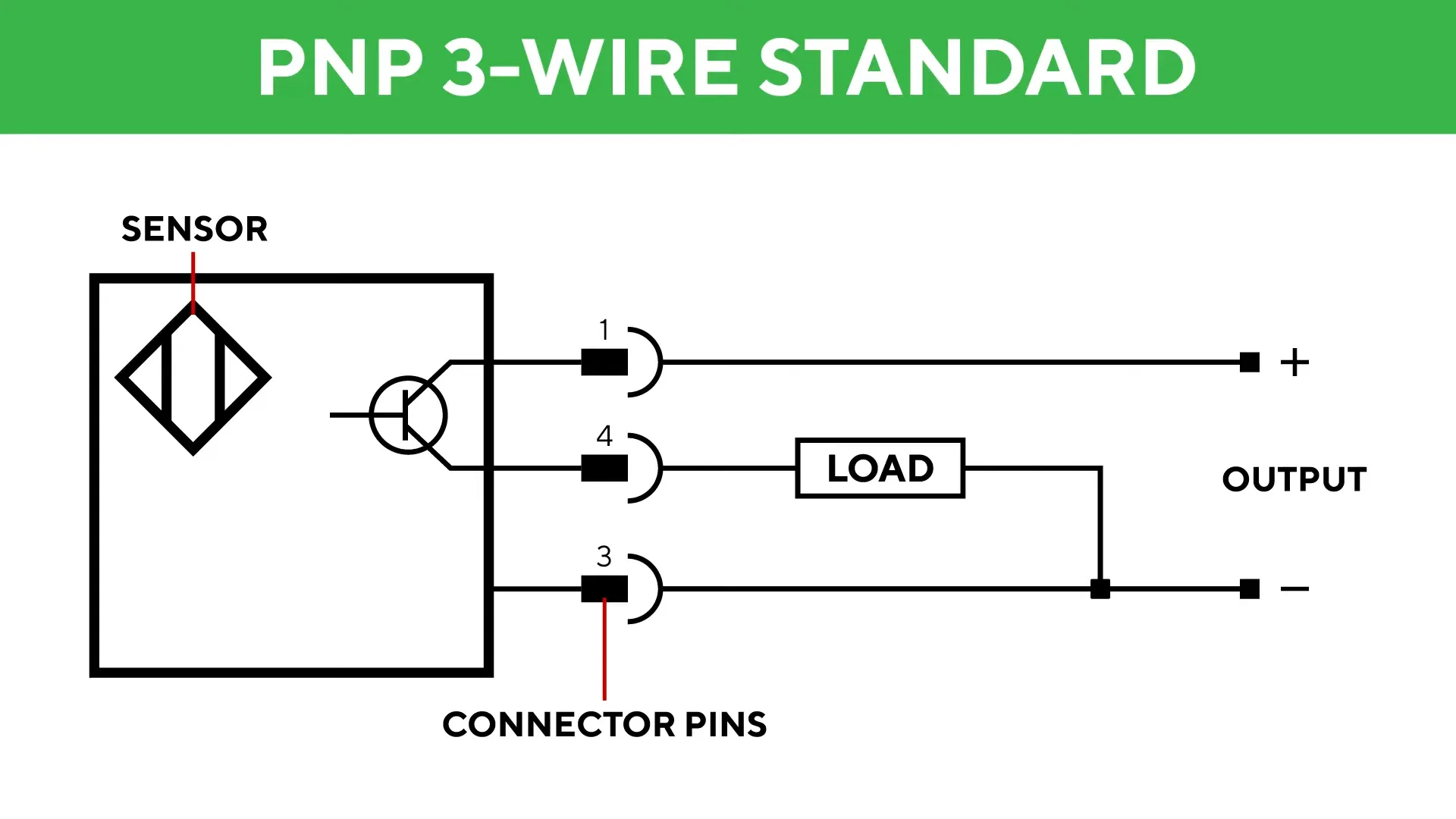

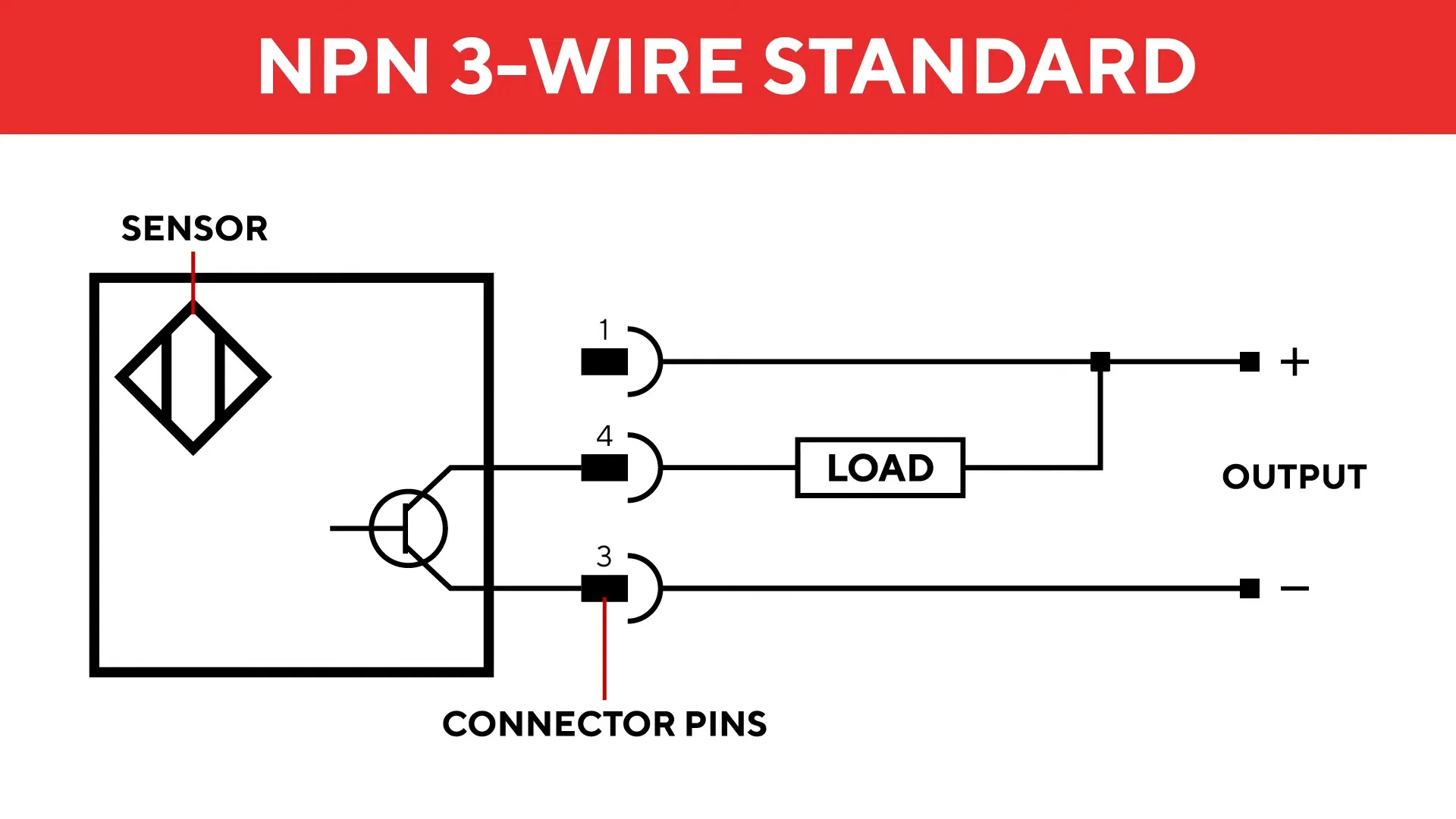

PNP and NPN configurations for 3-wire sensors differ primarily in their output switching and wiring connections. In PNP sensors, the output switches to the positive supply voltage when activated, while NPN sensors switch to ground. This distinction affects how the load is connected:

- PNP (sourcing): The load is connected between the sensor output and the negative supply (L-).

- NPN (sinking): The load is connected between the sensor output and the positive supply (L+).

Wiring colors typically follow a standard convention:

- Brown: Positive supply voltage

- Blue: Negative supply/ground

- Black: Output signal

When selecting between PNP and NPN for a 3-wire sensor connection, consider the compatibility with the control system inputs and the specific requirements of the application. PNP sensors are more commonly used in Europe, while NPN sensors have been traditionally preferred in Asia, though this trend is changing.

NPN Sensor PLC Wiring

When wiring an NPN type 3-wire proximity sensor to a PLC, it’s important to understand the correct connections to ensure proper functionality:

- Brown wire: Connect to the positive (+) terminal of the power supply

- Blue wire: Connect to the negative (-) terminal of the power supply

- Black wire (output): Connect to the PLC input terminal

The PLC input must be configured as a sourcing input to work with the NPN sensor. In this configuration, current flows from the PLC input through the sensor to ground when the sensor is activated. It’s crucial to verify that the PLC input card is compatible with NPN (sinking) sensors before making connections. Some PLCs offer configurable inputs that can accommodate both NPN and PNP sensors, providing flexibility in sensor selection.

When using multiple NPN sensors, they can share a common positive supply connection, which can simplify wiring in some applications. However, care must be taken to ensure the total current draw doesn’t exceed the power supply’s capacity.

Sensor Selection Criteria

When choosing between PNP and NPN sensors, consider the following factors:

- Compatibility: Ensure the sensor matches your control system’s input requirements. PNP sensors are typically used with sinking inputs, while NPN sensors work with sourcing inputs.

- Regional preferences: PNP sensors are more common in Europe and North America, while NPN sensors are often used in Asia.

- Electrical environment: PNP sensors generally offer better noise immunity, making them preferable in electrically noisy settings.

- System design: Consider power consumption, wiring complexity, and safety requirements. PNP sensors may consume more power but often require simpler wiring.

- Existing infrastructure: If upgrading or expanding a system, choose sensors compatible with your current setup to avoid costly rewiring or component replacements.

Always consult the specifications of your control devices and consider the specific needs of your application when making a final decision.

Identifying Sensor Type with multimeter

To determine if your proximity sensor is NPN or PNP, you can use a multimeter and follow these steps:

- Set the multimeter to DC voltage mode.

- Connect the sensor to a power supply (typically 24V DC).

- Connect the black probe of the multimeter to the sensor’s output wire (usually black).

- Connect the red probe to the positive power supply wire (usually brown).

If the multimeter reads a voltage close to the supply voltage when the sensor is activated, it’s a PNP sensor. If there’s no voltage reading when activated, it’s likely an NPN sensor.

Alternatively, check the sensor’s datasheet or look for markings on the sensor body. PNP sensors are often labeled with a “+” symbol, while NPN sensors may have a “-” symbol.

Remember that PNP sensors source current (connect to positive when activated), while NPN sensors sink current (connect to ground when activated). This fundamental difference in operation is key to identifying and correctly wiring these sensor types in your control system.

Cost Implications of Sensor Types

The choice between PNP and NPN proximity sensors can have significant cost implications for industrial automation systems:

- Component costs: NPN sensors are generally less expensive to manufacture, making them more cost-effective for large-scale implementations.

- Power consumption: PNP sensors typically draw more current, potentially increasing long-term energy costs in systems with numerous sensors.

- Wiring complexity: NPN sensors may require additional components like pull-up resistors in some applications, potentially increasing installation costs.

- Inventory management: Standardizing on one sensor type (either PNP or NPN) can reduce inventory costs and simplify maintenance.

- Regional availability: In regions where one type is more prevalent, the more common sensor may be less expensive due to higher supply and competition.

When considering cost implications, it’s crucial to evaluate not just the initial sensor price, but also long-term operational expenses and system integration costs to determine the most economical solution for a specific application.

Integration with IoT Systems

PNP and NPN proximity sensors play a crucial role in integrating industrial automation systems with the Internet of Things (IoT). Their distinct output characteristics influence how sensor data is collected and transmitted to IoT platforms:

PNP sensors, with their positive voltage output when activated, are often preferred in IoT applications due to their compatibility with many microcontrollers and single-board computers used as IoT gateways. The high-level signal they provide can be directly read by digital input pins on devices like Raspberry Pi or Arduino boards.

NPN sensors, while requiring a pull-up resistor for proper signal interpretation, can be advantageous in low-power IoT deployments. Their current-sinking nature allows for simpler power management in battery-operated IoT devices.

When integrating these sensors into IoT systems, considerations include:

- Signal conditioning: IoT gateways may require additional circuitry to adapt sensor outputs to appropriate voltage levels for digital processing.

- Communication protocols: Sensors are often connected to IoT gateways using industrial protocols like Modbus or IO-Link before data is transmitted to cloud platforms via protocols such as MQTT or CoAP.

- Edge computing: Local processing of sensor data can be implemented to reduce latency and bandwidth requirements, with PNP sensors often providing more straightforward integration with edge devices.

The choice between PNP and NPN sensors in IoT applications ultimately depends on the specific requirements of the IoT architecture, power constraints, and the capabilities of the chosen IoT gateway devices.