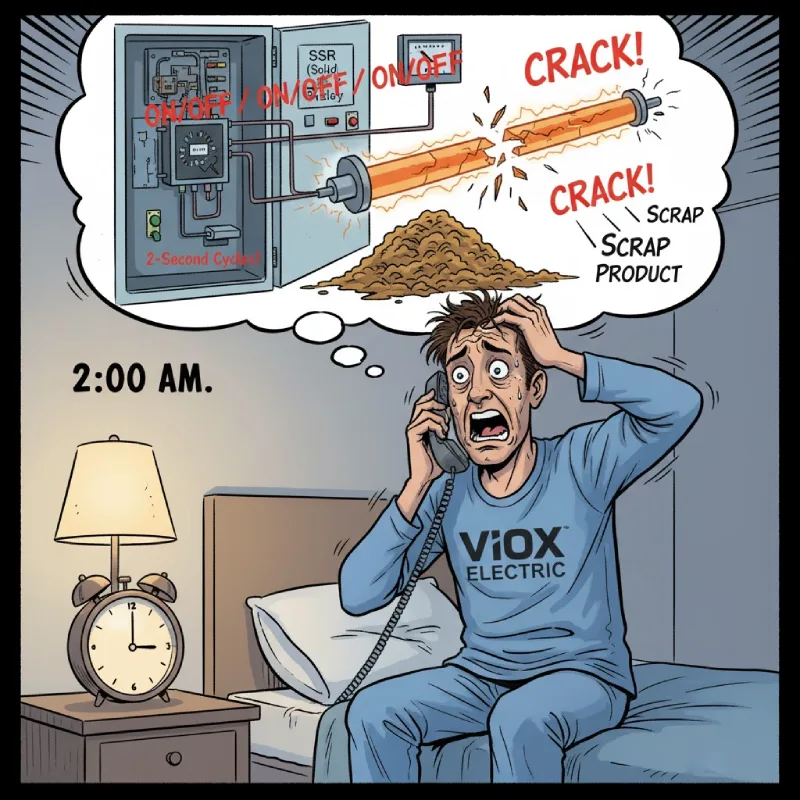

The Call That Every Engineer Dreads

You’re six months into a new installation. The control panel passed commissioning with flying colors. The temperature controller shows stable readings. Then your phone rings at 2 AM.

“Line 3 is down again. Another heater element failed. That’s the third one this quarter.”

You specified a Solid State Relay (SSR) to control the heating elements—a straightforward choice. It was cheaper than an SCR power controller, easier to wire, and “everyone uses them.” The electrical contractor didn’t question it. The budget committee approved it. What could possibly go wrong?

Here’s what went wrong: That SSR has been cycling your heater on and off every 2-5 seconds, 17,280 times per day, subjecting your nichrome resistance wire to brutal thermal shock. Meanwhile, your temperature swings are causing quality defects, your maintenance costs are spiraling, and your production manager is demanding answers.

This scenario plays out in plants worldwide, costing thousands in premature equipment failure and production losses—all because of a misunderstood component selection. The question isn’t just “SSR or SCR?” It’s “How do I permanently eliminate heater failure, achieve precision control, and stop wasting money on the wrong solution?”

Why SSRs Fail: The Thermal Cycling Trap

The culprit behind premature heater failure is a phenomenon called thermal cycling—the repeated heating and cooling of resistance elements. Here’s why it matters:

Electric heaters use nickel-chromium (nichrome) wire that resists electrical current, converting energy into heat. When an SSR switches on, the wire heats up rapidly. When it switches off 2-5 seconds later, the wire cools down. This expansion-contraction cycle repeats continuously—over 17,000 times per day in a typical process.

Each cycle creates microscopic stress fractures in the wire’s crystalline structure. Over months, these fractures propagate, leading to a condition called hydrogen embrittlement. The wire becomes brittle, its resistance increases, hot spots develop, and eventually it fails—usually at the worst possible moment.

The brutal math: An SSR operating in a standard 8-hour shift creates roughly 5,760 thermal cycles per day. Multiply that by 250 working days, and you’re subjecting your heater to 1.44 million thermal shock events per year. Even high-quality heaters aren’t designed for this abuse.

Meanwhile, SCRs switch at 1/60th of a second (matching the 60Hz AC power frequency in North America). Instead of the wire cooling between cycles, it maintains a steady operating temperature. The difference between 2-second intervals and 0.0167-second intervals isn’t just faster switching—it’s the difference between thermal shock and thermal stability.

The Answer: Understanding the 4 Enormous Differences Between SSR and SCR

The solution to heater failure, control precision, and total cost of ownership lies in understanding four critical differences between these components—differences that determine whether your system thrives or struggles.

Difference #1: Naming and Core Identity

SSR (Solid State Relay) refers to an electronic switching device that uses semiconductor components—typically thyristors or TRIACs—for contactless switching. It’s designed as a direct replacement for mechanical contactors and relays.

SCR (Silicon Controlled Rectifier) is a type of thyristor used in power control applications. In industrial contexts, “SCR” often refers to an SCR-based power controller or SCR relay module that regulates voltage or current through phase-angle control or zero-cross switching.

Belangrijkste afhaalmaaltijd: The name difference reveals their DNA. SSRs are schakelaars. SCRs are power regulators. This distinction drives everything else.

Difference #2: Control Function—Digital vs. Analog

This is where most specification errors occur.

SSRs provide binary control: They’re either fully ON (conducting 100% of available voltage) or fully OFF (blocking all current). There’s no middle ground. When your temperature controller calls for heat, the SSR closes; when it calls for cooling, the SSR opens. It’s a digital, bang-bang control strategy.

SCRs provide analog control: They adjust output power from 0-100% by controlling the conduction angle within each AC cycle. Using phase-angle firing or burst firing, an SCR can deliver precisely 47% power, 82% power, or any value needed—smoothly and continuously.

Think of it this way: Controlling temperature with an SSR is like driving a car with only two pedal positions—floor it or slam the brakes. Controlling with an SCR is like having full throttle modulation. Which one gets you to your destination smoothly?

Pro-Tip for Engineers: If your process requires temperature stability better than ±5°C, or if you’re controlling inductive loads (transformers, motors), phase-modulated power from an SCR is essential. SSRs will create temperature oscillations that show up as quality defects in your product.

Difference #3: Control Signal Architecture

SSRs accept simple digital signals:

- DC control: 3-32VDC (typical from PLCs, microcontrollers, or digital outputs)

- AC control: 70-280VAC (directly from line voltage switches)

When the control signal is present, the SSR conducts. When removed, it opens. It’s plug-and-play simplicity.

SCRs accept analog modulation signals:

- 4-20mA current loop (industry standard for analog control)

- 0-5VDC or 0-10VDC (common from temperature controllers)

- Potentiometer inputs (for manual trim control)

- PID controller outputs (for closed-loop temperature regulation)

The SCR’s control circuitry interprets these analog signals and adjusts the firing angle accordingly, providing proportional power output.

Installation Reality Check: Yes, SCRs require more sophisticated control infrastructure. But if your process is worth controlling precisely, you’re already using a PID temperature controller that outputs these signals. The integration isn’t complex—it’s appropriate for the application.

Difference #4: Application Domain—When to Use Which

This is where your specification lives or dies.

SSRs excel in:

- Low-to-medium power switching (<25-30A, single-phase)

- Non-critical ON/OFF control (lighting, simple heating, solenoid activation)

- High-frequency switching where speed matters more than thermal stability

- Kostengevoelige toepassingen where upfront cost drives the decision

- Simple control architectures (relay replacement, PLC digital outputs)

SCRs dominate in:

- Toepassingen met hoog vermogen (>30A, especially three-phase loads)

- Precision temperature control (furnaces, ovens, semiconductor processing, pharmaceutical applications)

- Inductive or heavy resistive loads (transformers, industrial heaters, large motors)

- Applications requiring long heater life (where thermal cycling would cause premature failure)

- Kritische processen where temperature stability directly impacts product quality or safety

Pro-Tip from the Field: Here’s the rule most engineers miss: If your heater costs more than $500 to replace, or if replacing it requires shutting down production, use an SCR. The 2-3x upfront cost premium pays for itself the first time you don’t have an emergency maintenance call.

The 4-Step Selection Framework: Choosing the Right Controller

Now that you understand the differences, here’s how to make the correct choice systematically.

Step 1: Calculate Your Real Power Requirements and Load Type

Don’t just look at the heater nameplate. Calculate actual current draw and determine load type.

For resistive loads (heaters):

- Single-phase: Current (A) = Power (W) ÷ Voltage (V)

- Three-phase: Current (A) = Power (W) ÷ (√3 × Voltage × Power Factor)

Critical decision point: If your load exceeds 25-30A on a single phase, or if you’re controlling a three-phase heater bank, SSRs become problematic. They generate significant heat (approximately 1.5W per amp per leg), require massive heat sinking, and suffer performance derating.

For inductive loads (transformers, motors): Use an SCR. Period. The inrush current and reactive power demands will destroy SSRs or drastically shorten their life.

Step 2: Define Your Control Precision Requirements

Ask yourself: What temperature tolerance does my process demand?

- ±10-15°C acceptable? An SSR with a good PID controller might suffice.

- ±3-5°C required? You’re in the transition zone—consider an SCR.

- ±1-2°C critical? An SCR with phase-angle control is non-negotiable.

Real-world example: A plastic extrusion line requires ±2°C stability to maintain product dimensional tolerances. An SSR’s bang-bang control creates temperature oscillations that directly translate to dimensional variation in the extruded part. Switching to SCR control reduced scrap rates by 40% in one documented case.

Step 3: Perform the True Total Cost of Ownership (TCO) Analysis

This is where the “SSRs are cheaper” myth collapses.

SSR TCO calculation:

- Initial cost: $150-300 (depending on rating)

- Expected heater replacement: Every 12-18 months due to thermal cycling

- Heater replacement cost: $800-2,000 (parts + labor + downtime)

- 5-year TCO: $4,000-10,000+

SCR TCO calculation:

- Initial cost: $500-900 (2-3x higher)

- Expected heater replacement: Every 5-7 years (minimal thermal cycling)

- Heater replacement cost: $800-2,000

- 5-year TCO: $900-2,900

The TCO advantage of SCRs: 60-70% lower over equipment lifetime.

Additionally, SCRs reduce:

- Emergency maintenance calls (fewer failures)

- Production downtime (higher reliability)

- Voltage sag on the electrical grid (smooth power draw reduces inrush)

- Electromagnetic interference (cleaner switching reduces electrical noise)

Step 4: Consider Installation Environment and Support Infrastructure

Go with SSR if:

- You have limited panel space and cooling capacity

- Your control system only provides digital outputs (though analog I/O cards are inexpensive)

- Your maintenance team is unfamiliar with SCR technology (though training pays dividends)

- The application truly is non-critical and simple ON/OFF control is adequate

Go with SCR if:

- You have adequate panel cooling or can add heat sinks/fans (both generate heat—SCRs just manage it better)

- You need grid-friendly soft-start (SCRs eliminate inrush current spikes)

- You’re controlling critical processes where failure costs exceed the component cost difference

- You want to future-proof the installation (SCRs provide upgrade paths to advanced control strategies)

Pro-Tip on Heat Management: Both SSRs and SCRs generate approximately 1.5W per amp per leg switched. For a 40A load, that’s 120W of heat in your panel. The difference is that SCRs are typically designed with better thermal interfaces and clearer derating curves. When evaluating specs, check the ambient temperature at which the device is rated—some manufacturers rate at 25°C (unrealistic), others at 40-50°C (honest engineering).

Conclusion: Make the Right Choice, Save Your Equipment

The difference between SSR and SCR isn’t just about switching speed or control methods—it’s about matching the right tool to the real-world demands of your application.

By following this 4-step framework, you will:

- Eliminate premature heater failure caused by thermal cycling damage

- Achieve precise temperature control that improves product quality and reduces scrap

- Reduce total cost of ownership by 60-70% through extended equipment life

- Prevent emergency downtime that disrupts production schedules and revenue

The engineer who called at 2 AM could have avoided their crisis with one decision: recognizing that their high-power, precision-critical application demanded an SCR, not an SSR. Don’t let upfront cost drive a decision that will haunt you for years.

Your next step: Review your existing installations. If you’re using SSRs to control loads over 25A, or if you’re experiencing frequent heater failures, run the TCO calculation. The numbers will tell you what needs to change.

For critical applications—semiconductor processing, pharmaceutical manufacturing, food safety systems, or any process where temperature precision directly impacts your bottom line—specify an SCR power controller from the start. Your heaters will last longer, your process will run more stably, and your maintenance team will thank you.

The right component choice isn’t the cheapest one—it’s the one that solves the real problem.