Friday. 4:45 PM. Your dryer stops mid-cycle.

By the time you trace the problem to a blown 30-amp fuse in the disconnect box outside, you’re already mentally shopping for a replacement—and here’s the thought that crosses your mind: “Why not just replace this whole fused disconnect with a modern breaker disconnect? Same 30 amps, right?”

Wrong. And the reason why could save your house.

The question seems straightforward—Reddit user Fatal_Error87 asked it recently, and thousands of homeowners ask it every year. They have a 100-amp fuse panel feeding a 30-amp fused disconnect for their dryer. The fuses are old-school, inconvenient, and they want to modernize with a breaker. What could possibly go wrong?

Everything. And the danger is invisible until it’s not.

Why This Swap Seems Obvious (And Why You’re About to Make a $12,000 Mistake)

The logic sounds bulletproof. You’re replacing a 30A protection device with another 30A protection device. The wire stays the same. The load (your dryer) stays the same. The main panel stays the same. It’s like swapping a manual transmission for an automatic—different mechanism, same output.

Except it’s nothing like that.

Here’s what’s actually happening: You’re about to create what electricians call a “protection gap”—a section of wire that can carry more current than it’s rated for, protected by nothing except the hope that physics takes the day off.

Welcome to The Protection Pyramid.

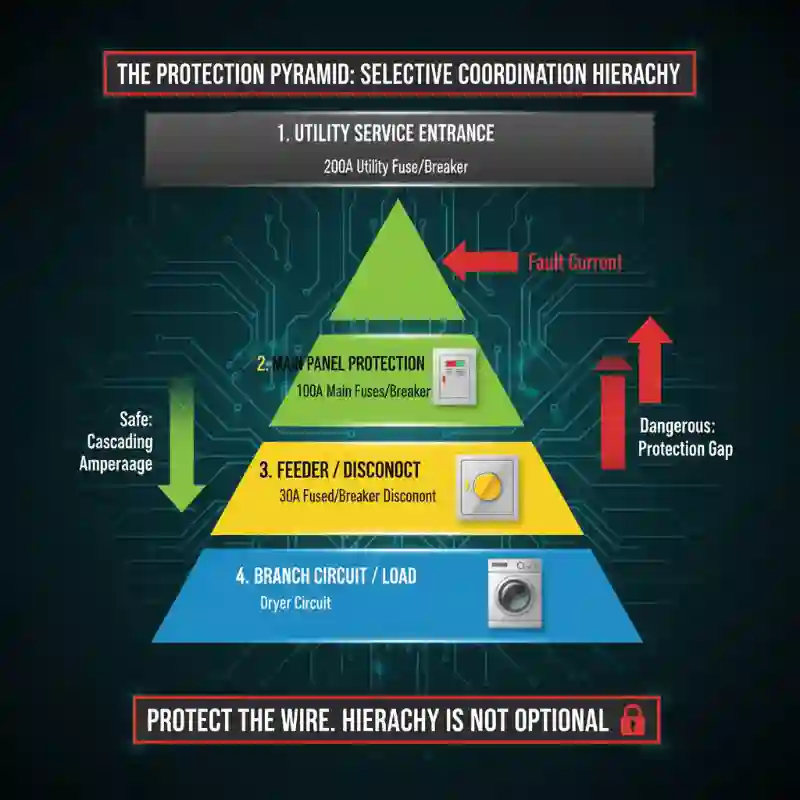

In every properly designed electrical system, protection devices form a hierarchy. The main breaker or fuse is largest. Below it, feeder breakers are smaller. Below those, branch circuit breakers are smaller still. This isn’t arbitrary aesthetics—it’s the fundamental principle that keeps your house from burning down.

When you have a 100A fuse panel feeding a 30A disconnect, the system works because the 100A fuses “see” everything. They’re protecting the conductors running from the main panel to the disconnect. Those conductors need to be sized for the full 100A upstream protection—not the 30A load.

Now you want to put a 30A breaker in the disconnect. The breaker will trip at 30A. Perfect, right?

Not even close. Because under a fault condition—say, when your dryer’s heating element shorts to ground—here’s what happens: Thousands of amps want to flow through that circuit. The 30A breaker “sees” this and tries to trip. But breakers aren’t instant. They take time to open—anywhere from a few cycles to several seconds depending on the fault current.

During that time, the 100A fuses upstream are also “seeing” this fault current. And here’s the problem: They don’t know your 30A breaker exists. They don’t wait for it. They don’t coordinate with it. If they trip first (and they often will), your entire 100A panel goes dark.

Worse? If the conductor between the main panel and the disconnect is sized only for 30A (common in these setups), you’ve just created The Invisible Wire—a conductor that can be overloaded by its own upstream protection.

That wire becomes the fuse. And unlike a fuse in a box, it “opens” by melting inside your wall.

The Protection Pyramid: Why Your 100A Fuses Don’t Know Your 30A Breaker Exists

The concept electrical engineers call “selective coordination” sounds academic. It’s not. It’s the difference between a tripped breaker and a house fire.

Selective coordination means this: When a fault occurs on a circuit, only the overcurrent device immediately upstream of the fault opens. Everything else upstream stays closed. If your dryer shorts out, the disconnect opens. The main panel stays energized. You fix the dryer, reset the disconnect, life continues.

Without selective coordination? The fault cascades upstream. The disconnect trips. The main panel trips. Maybe even the utility disconnect trips. Now you’re in the dark, and you have no idea where the actual problem is. More critically, during the time both devices are competing to trip, the conductor between them might be carrying more current than it’s rated for.

Here’s the specific problem with the Reddit scenario:

The Setup:

- Main panel: 100A fuses

- Conductor from main to disconnect: Unknown size (this is critical)

- Original disconnect: 30A fuses

- Proposed replacement: 30A breaker disconnect

The Fault Scenario:

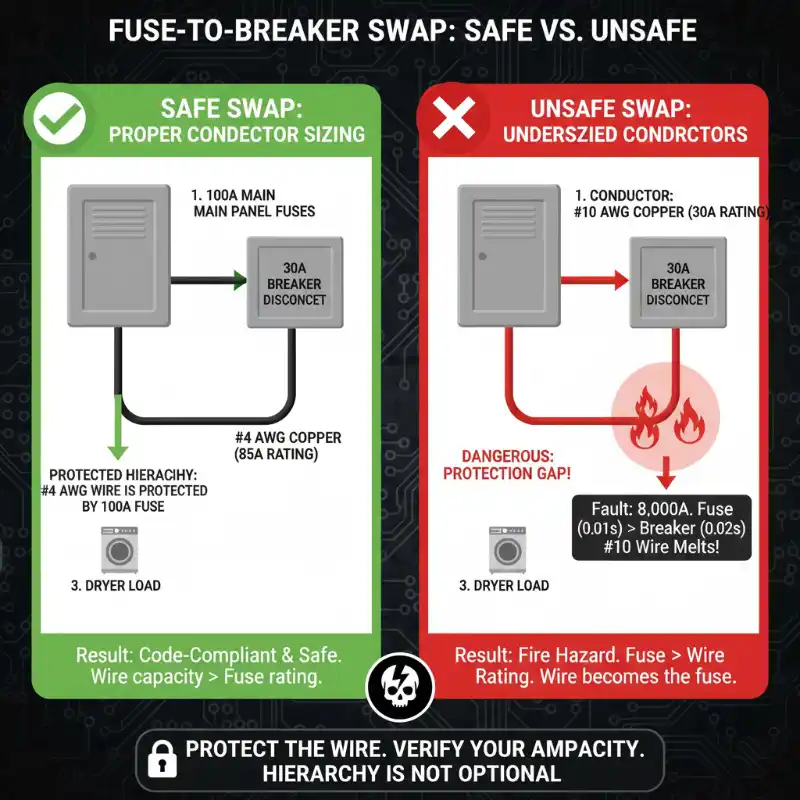

Let’s say your dryer develops a line-to-ground fault. The available fault current at the disconnect might be 8,000 amps (typical for residential, depending on transformer size and conductor length).

What Happens:

8,000 amps tries to flow through the fault.

The 30A breaker “sees” this massive overcurrent and begins to trip.

The 100A fuses upstream also “see” this 8,000 amps.

Both devices have time-current curves that determine how fast they react.

The Critical Timing Issue:

Class RK5 fuses (common in older panels) will clear an 8,000A fault in approximately 0.01 seconds—one-hundredth of a second. A thermal-magnetic 30A breaker might take 0.02 to 0.05 seconds to clear the same fault, depending on the breaker type.

Do you see it? The fuses trip faster than the breaker.

Your 100A main panel goes dark. The 30A breaker never had a chance to do its job. And during those extra 0.01 to 0.04 seconds? The conductor between the panels—The Invisible Wire—is carrying 8,000 amps.

If that conductor is #10 AWG (rated for 30A under NEC Table 310.16), it should be protected by a 30A device maximum. But it’s actually being “protected” by 100A fuses. Those extra 70 amps of “protection gap” don’t matter during normal operation. They matter enormously during a fault.

The wire heats at a rate proportional to I²R. At 8,000 amps, even for 0.02 seconds, a #10 AWG conductor can reach temperatures exceeding 200°C—well above the 90°C rating of typical THHN insulation.

Pro-Tip #1: The Protection Pyramid Rule:

Upstream protection must ALWAYS be larger than downstream, but only if the CONDUCTORS between them are sized for the upstream protection. Break this, and you’re creating a fire hazard the inspector will never see—until it’s too late.

This is why you can’t just swap fuses for breakers without understanding what’s protecting what.

The One Scenario Where This Actually Works (And How to Know If You’re In It)

There IS a scenario where replacing a fuse disconnect with a breaker disconnect is code-compliant and safe. But it’s probably not the scenario you’re in.

Scenario 1: You Have Properly Sized Feeder Conductors

If the conductors running from your 100A fuse panel to the 30A disconnect are sized for 100A (or the next size down that’s protected by those 100A fuses), you’re golden.

Here’s what this looks like:

- Main panel: 100A fuses

- Feeder conductors: #4 AWG copper (rated 85A at 75°C) or larger

- Original disconnect: 30A fuses

- Replacement: 30A breaker disconnect

Why this works: The feeder conductors are protected by the 100A fuses. Under a fault condition, even if the fuses clear before the breaker, the conductors can handle it—they’re rated for it. The 30A breaker exists purely to provide overload protection for the dryer circuit and a local disconnect point.

How to verify you’re in this scenario:

- Turn off power at the main panel (obvious, but I’m saying it anyway)

- Remove the cover at both the main panel and disconnect

- Check the conductor size printed on the insulation (should say something like “10 AWG” or “8 AWG”)

- Cross-reference with NEC Table 310.16 for ampacity

- Verify the conductor ampacity meets or exceeds the upstream fuse rating

If your feeder is #4 AWG or larger? You’re in Scenario 1. Swap away (with proper workmanship, of course).

If your feeder is #10 AWG (30A rating)? Keep reading, because you’re in dangerous territory.

Scenario 2: The Tap Rule Exception (The 10-Foot Lifeline)

NEC 240.21(B)(1) provides an exception called the “10-foot tap rule.” It allows you to run conductors that are smaller than the upstream protection device, but only under very specific conditions.

The 10-Foot Tap Rule Requirements:

- The tap conductor length must not exceed 10 feet

- The tap conductor ampacity must be at least 1/10th the rating of the upstream OCPD

- The tap conductors must terminate in a single overcurrent device

- The tap conductors must be installed in raceway if they leave the enclosure

Applying this to the Reddit scenario:

Upstream protection: 100A fuses

Minimum tap conductor ampacity: 100A ÷ 10 = 10A

Wait. A #10 AWG conductor is rated for 30A. That’s well above the 10A minimum. So the tap rule works, right?

Not so fast. Read requirement #1 again: “not exceed 10 feet.”

How far is your disconnect from your main panel? For most residential dryer disconnects, the answer is: “more than 10 feet.” They’re often 20, 30, or 50 feet away—wherever the utility placed the meter and wherever the builder put the laundry room.

If your disconnect is more than 10 feet from the main panel, the 10-foot tap rule doesn’t apply. There’s a 25-foot tap rule [NEC 240.21(B)(2)], but it requires the tap conductor to have an ampacity of at least 1/3 the upstream OCPD rating. For 100A fuses, that’s 33.3A minimum—which #10 AWG (30A) doesn’t meet.

Pro-Tip #2: The Tap Rule Trap:

That wire between your main panel and disconnect? It needs protection too. If it’s sized for 30A but fed by 100A fuses, you’ve got exactly 10 feet of code-compliant leeway. Beyond that? You’re in violation, and it’s your house on the line.

The brutal reality: Most residential fuse-to-breaker swaps DON’T meet the requirements for safe replacement.

4-Step Method to Determine If Your Fuse-to-Breaker Swap Is Safe (or Deadly)

Before evaluating whether to replace a fuse disconnect with a breaker, run through these four steps. They’ll tell you whether you’re upgrading your electrical system or creating a liability.

Step 1: Identify ALL Upstream Protection Devices

Start at the disconnect and work backwards to the utility.

What to document:

- Disconnect fuse rating: [Example: 30A]

- Main panel fuse ratings: [Example: 100A]

- Meter base fuse/breaker (if present): [Example: 200A]

Why this matters: You need to map the entire protection hierarchy. Every conductor must be protected by the upstream device. No exceptions.

If you find multiple levels of protection (meter base fuses → main panel fuses → disconnect fuses), you need to analyze each level of conductor sizing.

Common mistake: Forgetting about protection at the meter base. If your utility installed a 200A meter main with fuses, those matter too.

Step 2: Verify Your Conductor Sizing

This is where most DIYers discover they’re not in a safe scenario.

Wat u moet controleren:

- Turn off all power (use a non-contact voltage tester to verify)

- Open the main panel and disconnect enclosures

- Find the conductor size marking on the insulation jacket

Should read “10 AWG,” “8 AWG,” etc.

If you see “12-2” or “10-3,” the first number is the gauge

Measure the length of conductor run (use a tape measure if accessible, estimate if in conduit)

Compare to NEC ampacity tables:

- #14 AWG copper: 15A max (75°C column)

- #12 AWG copper: 20A max

- #10 AWG copper: 30A max

- #8 AWG copper: 40-50A (depending on insulation)

- #6 AWG copper: 55-65A

- #4 AWG copper: 70-85A

The critical question: Is the conductor ampacity equal to or greater than the upstream fuse rating?

If YES: Proceed to Step 3.

If NO: Your conductor is undersized for the upstream protection. You’re relying on a tap rule exception. Proceed to Step 3.

Pro-Tip #3: The “conductor must be protected” rule:

Every conductor’s ampacity must be matched to its overcurrent protection. In the real world, this means your #10 AWG feeder (30A rating) cannot be protected by a 100A fuse unless it meets a specific tap rule exception. Miss this, and you’ve just made your wire the weakest link.

Step 3: Check for Tap Rule Compliance

If your conductors are undersized for the upstream protection (like #10 AWG fed by 100A fuses), you MUST comply with tap rules.

For the 10-foot tap rule [NEC 240.21(B)(1)]:

Calculate minimum conductor ampacity required:

Formula: Upstream OCPD ÷ 10 = Minimum ampacity

Example: 100A ÷ 10 = 10A minimum

Check your conductor length:

Measure from the upstream OCPD (100A fuses) to the downstream OCPD (where the 30A breaker will go)

Include all conductor run—inside panels, in conduit, everywhere

Decision point:

If length ≤ 10 feet AND conductor ampacity ≥ 10% of upstream OCPD → Tap rule complies, proceed to Step 4

If length > 10 feet → Check 25-foot tap rule

For the 25-foot tap rule [NEC 240.21(B)(2)]:

Calculate minimum conductor ampacity required:

Formula: Upstream OCPD ÷ 3 = Minimum ampacity

Example: 100A ÷ 3 = 33.3A minimum

Your #10 AWG conductor (30A rating) does NOT meet this requirement. You’d need at least #8 AWG (40-50A rating).

Decision point:

If length ≤ 25 feet AND conductor ampacity ≥ 33% of upstream OCPD → Tap rule complies, proceed to Step 4

If neither tap rule applies → STOP. Your swap is not code-compliant. Jump to alternative solutions below.

Pro-Tip #4: The 10-Foot Lifeline:

NEC 240.21(B)(1) gives you exactly 10 feet to run undersized conductors—but only if they’re at least 1/10th the upstream protection rating. Beyond that? You need full protection, which means either upsizing the conductors or downsizing the upstream fuses.

Step 4: Evaluate Selective Coordination

Even if your conductors are properly sized and your tap rules check out, there’s one more consideration: Will the system coordinate properly?

The question: Under a fault condition, will the 30A breaker trip before the 100A fuses?

Why this matters: If the fuses trip first, you lose power to the entire panel. Not a code violation, but a nuisance and a troubleshooting nightmare.

How to check:

This requires time-current curves (TCC) for both the upstream fuses and downstream breaker. For DIYers, this is beyond practical analysis. The short version:

Fuses generally react faster than breakers at high fault currents.

Current-limiting fuses (Class RK1, RK5, J, T) are especially fast.

For residential applications with standard thermal-magnetic breakers, assume the fuses will trip first at high fault currents.

Practical implications:

System will be safe (if conductors are properly sized).

System will be annoying (main panel trips instead of just the disconnect).

For true coordination, you’d need electronic trip breakers or specific fuse/breaker combinations that manufacturers have tested.

For most homeowners: If Steps 1-3 check out, accept that coordination won’t be perfect but the system will be safe.

The Safe Solution: Three Options That Won’t Burn Your House Down

So you’ve run through the 4-step method and discovered your fuse-to-breaker swap isn’t code-compliant. What now?

You have three legitimate options:

Option 1: Keep the Fused Disconnect (Boring But Safe)

Cost: $0-$15 (for replacement fuses)

What to do: Replace the blown fuses, stock a few spares, move on with life.

Why this works: The system is already code-compliant. Fuses are reliable, they provide excellent short-circuit protection, and they’re cheap to replace. Yes, you have to keep fuses on hand. No, this isn’t the end of the world.

Best for: Homeowners who realize the current setup isn’t broken, just old-school.

Option 2: Upgrade the Feeder Conductors (The Right Way)

Cost: $200-$800 (depending on length and labor)

What to do:

- Replace the #10 AWG feeder with #4 AWG or larger

This brings the conductor ampacity in line with the 100A upstream protection. Only then replace the fuse disconnect with a breaker disconnect.

Why this works: You’re eliminating the tap rule dependency. The feeder conductors can handle the full 100A upstream protection. The 30A breaker becomes purely overload protection for the dryer circuit.

Code compliance: NEC 240.4 requires conductors to be protected at their ampacity. By upsizing to #4 AWG (85A at 75°C), you’re within the 100A fuse protection.

Best for: Homeowners planning other electrical work who can bundle the labor costs.

Pro-Tip:This is the “do it once, do it right” option. Yes, it’s more expensive up front. But you’ll never worry about this circuit again, and the next homeowner gets a properly-upgraded system.

Option 3: Downsize the Upstream Protection (The Surgical Approach)

Cost: $50-$200 (fuse holder modification + electrician time)

What to do:

- Replace the 100A fuses in the main panel with 30A or 40A fuses (same fuse class)

- Verify the conductors to the disconnect are properly protected by the new fuse size

- Replace the fused disconnect with a breaker disconnect (now safely redundant)

Why this works: You’re bringing the upstream protection in line with the conductor ampacity. A 30A conductor protected by a 30A fuse is code-compliant. The breaker disconnect adds a local disconnect point without creating protection gaps.

Code compliance: NEC 240.4(B) allows conductor protection at the next standard fuse size up (if conductor ampacity falls between standard sizes). For a 30A conductor, 30A or 35A fuses are appropriate.

Caution: This only works if the 100A fuses aren’t protecting OTHER loads in the main panel. If those fuses feed multiple circuits, downsizing them could create nuisance tripping on other circuits. You’d need a dedicated fused disconnect between the main panel and the dryer disconnect—basically, adding another layer of protection.

Best for: Systems where the 100A fuses feed ONLY the dryer circuit (uncommon but possible).

Real talk: This option is rare in residential. Most 100A fuse panels feed the entire house, not just one appliance. But if you’re in the 5% of installations where this applies, it’s the cheapest path to a breaker disconnect.

The Bottom Line: Ask the Right Question Before Making the Wrong Move

You came here with a simple question: “Can I replace a fuse disconnect with a breaker disconnect?”

The answer is: Maybe. But only if you understand what’s protecting what.

The Protection Pyramid isn’t optional. Every conductor in your electrical system needs overcurrent protection matched to its ampacity. When you have 100A fuses feeding a 30A disconnect through #10 AWG conductors (30A rated), you’re violating this principle unless you meet specific tap rule requirements.

Most residential installations don’t meet these requirements. The disconnect is more than 10 feet from the main panel. The conductors are undersized for the upstream protection. The system “works” with fuses because the fuses provide both overcurrent protection AND serve as the disconnect. Swapping to breakers breaks the protection hierarchy.

Here’s what the Reddit poster—and thousands like them—need to understand:

The fact that you asked is what saved you. You didn’t assume. You didn’t just grab a breaker disconnect from the hardware store and wing it. You asked whether it was safe.

That question—that one moment of “wait, is this actually okay?”—is the difference between a code-compliant upgrade and an insurance claim.

The statistics aren’t theoretical: According to the U.S. Fire Administration and National Fire Protection Association research, approximately 30,000-48,000 electrical fires occur annually in U.S. homes, resulting in hundreds of deaths and over $1 billion in property damage. A significant percentage involve improperly modified electrical systems where protection devices don’t coordinate properly with conductors.

Your house might not burn down today. It might not burn down next year. But every time that dryer cycles on, every time a surge hits the circuit, you’re rolling dice with the wrong odds.

If you’ve read this far and realized your fuse-to-breaker swap isn’t safe, congratulations. You’re now ahead of 90% of DIYers who would have made the swap without checking.

If you’ve verified your system meets all the requirements and your swap IS safe, even better. You’ve done the due diligence.

Either way, you’re asking the right questions. And in electrical work, that matters more than you think.

Need help verifying your system’s protection hierarchy? VIOX ELEKTRISCHE offers comprehensive circuit protection solutions including properly coordinated fuse and breaker systems for residential and light commercial applications. Our engineering team can review your electrical system design for code compliance—because getting it right the first time is always cheaper than fixing it after the fire marshal shows up.

Gerelateerd

DC Circuit Breaker vs Fuse: The Ultimate Protection Selection Guide for DC Systems

MCB vs. Fuse: Why Your Motor Circuits Keep Failing (And the 3-Step Selection Guide)

Wat is een miniatuurstroomonderbreker (MCB): complete gids voor veiligheid en selectie