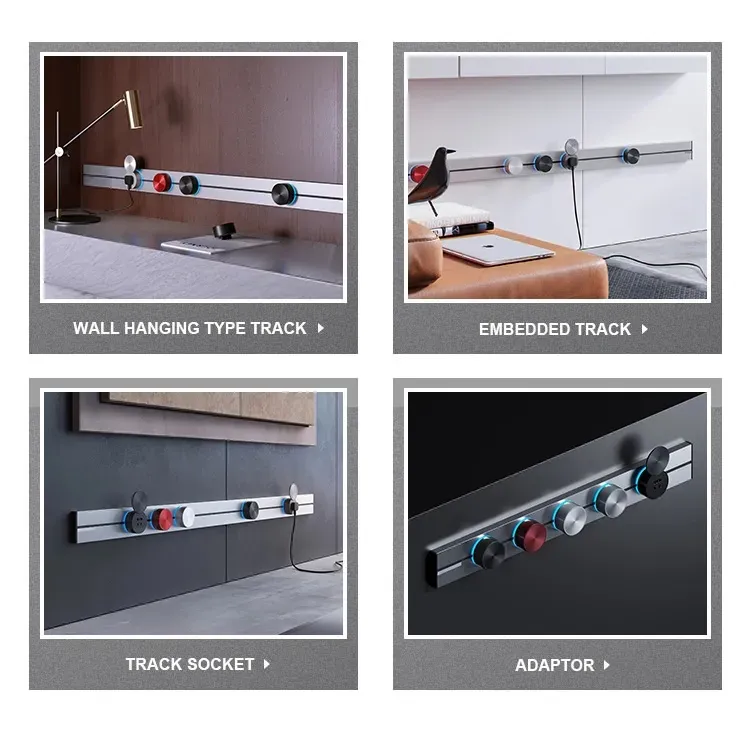

Contactdozen voor stroomrails, gemaakt van een gezandstraalde aluminiumlegering met anodisatiebehandeling, zijn innovatieve elektrische componenten die flexibele en aanpasbare oplossingen voor stroomlevering in verschillende omgevingen mogelijk maken.

Technieken voor materiaalverwerking

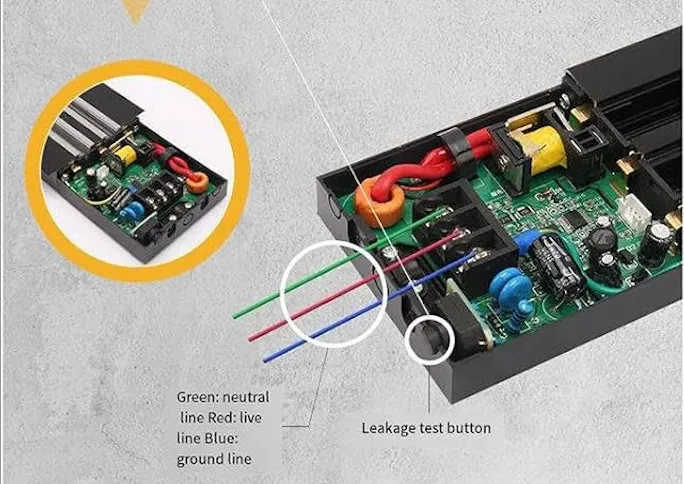

De basis van de productie van power track socket ligt in de nauwgezette verwerking van een aluminiumlegering, die wordt gezandstraald voor verbeterde oppervlakte-eigenschappen. Dit basismateriaal wordt vervolgens onderworpen aan een kleine anodisatiebehandeling, waardoor een beschermende coating ontstaat die de duurzaamheid en slijtvastheid verbetert. Voor de cruciale geleidende elementen maken fabrikanten gebruik van een koperlegering, zodat het eindproduct optimale elektrische prestaties en betrouwbaarheid biedt.

Overzicht technische specificaties

Contactdozen voor stroomrails zijn ontworpen voor een breed scala aan elektrische vereisten, met standaard nominale waarden die geschikt zijn voor verschillende toepassingen. Deze innovatieve apparaten werken binnen een spanningsbereik van 110V tot 250V en kunnen stromen van 25A tot 32A ondersteunen. Deze veelzijdigheid vertaalt zich in een indrukwekkend vermogen van 6200W tot 8000W, waardoor ze geschikt zijn voor zowel residentieel als commercieel gebruik. De afmetingen van het railsysteem zijn gestandaardiseerd voor consistentie, met een breedte van 86 mm en een dikte van 18 mm, terwijl ze aanpasbare lengtes bieden van 0,3 m tot 3,0 m om te voldoen aan diverse installatiebehoeften.

Details montage onderdelen

De assemblage van stroomrailcontactdozen omvat de integratie van verschillende belangrijke onderdelen om een functioneel en veilig elektrisch systeem te creëren. Geleidende rails worden in de rails ingebed en vormen de kern van het stroomverdelingsmechanisme. Deze rails zijn zorgvuldig geïsoleerd om de veiligheid van de gebruiker te garanderen en kortsluiting te voorkomen. Het assemblageproces bevat ook LED-indicatoren, verkrijgbaar in blauwe en rode weergaveopties, die visuele feedback geven over de operationele status van het stopcontact. Dankzij dit doordachte ontwerp kunnen gebruikers gemakkelijk actieve stopcontacten identificeren en de stroomtoevoer controleren, wat zowel het gebruiksgemak als de veiligheid in verschillende toepassingen verbetert.

Kwaliteitscontrolecertificeringen

Om de veiligheid en naleving van internationale standaarden te garanderen, ondergaan power track sockets strenge kwaliteitscontroleprocessen. Deze producten zijn gecertificeerd om te voldoen aan de CE-, RoHS- en CCC-normen. Het testen van de certificering is cruciaal voor het verifiëren van de elektrische veiligheid, milieuvriendelijkheid en algehele kwaliteit van de geproduceerde contactdozen. Deze uitgebreide aanpak van kwaliteitscontrole garandeert niet alleen de betrouwbaarheid van de stopcontacten, maar zorgt er ook voor dat ze geschikt zijn voor de wereldwijde markten en voldoen aan de verschillende wettelijke vereisten in verschillende regio's.