The 60-Second Decision That Affects Every Maintenance Call

You’re standing in the electrical aisle, comparing two junction boxes with identical specs—same IP rating, same dimensions, same price point. The only difference? One has a screw-on cover, the other a snap-on lid. You grab the screw version, figuring “more secure is better.”

Six months later, your maintenance team is on-site troubleshooting a sensor connection. The technician pulls out a screwdriver, removes four cover screws (two minutes), diagnoses the issue (thirty seconds), retrieves the screws from his pocket where he stashed them (another twenty seconds), and reinstalls the cover (two more minutes). Total time: nearly five minutes. Multiply that by twenty inspection visits per year, and you’ve burned nearly two hours of labor on a box that should have had a hinged cover from day one.

Junction box cover type directly impacts installation speed, maintenance accessibility, and long-term serviceability. Choose wrong, and you’re either wasting labor time or dealing with covers that pop open in high-vibration environments.

This guide breaks down how each cover type works, what trade-offs you’re accepting, and how to match cover design to your actual installation requirements.

Quick Answer: Junction Box Cover Types at a Glance

Three cover attachment methods dominate the junction box market, each optimized for different installation priorities:

Screw-On Covers: 4-6 threaded fasteners compress a gasket seal around the perimeter. Maximum environmental sealing (IP65-IP68), best vibration resistance, highest security. Trade-off: slowest access time (2-3 minutes per opening). Best for: outdoor installations, corrosive environments, low-inspection-frequency applications, and anywhere vibration or tampering is a concern.

Snap-On Covers: Spring clips or molded tabs lock the lid without tools. Fast installation and maintenance access (30-60 seconds). Trade-off: lower IP ratings (typically IP54-IP65) and reduced vibration resistance. Best for: indoor boxes, residential applications, and installations requiring frequent troubleshooting access in protected environments.

Hinged Covers: Stainless steel or polymer hinges keep the lid captive, with latches securing closure. Combines strong sealing (IP66+ available) with fast repeat access (10 seconds after initial setup). Trade-off: slight cost premium and larger footprint due to hinge mechanism. Best for: high-access-frequency locations like control panels, sensor junction points, and anywhere covers would otherwise get lost.

The decision comes down to three factors: how often you’ll open the box, what environmental protection you need, and whether vibration or security matter.

Screw-On Covers: Maximum Security and Environmental Sealing

Screw-on covers use threaded fasteners—typically four to six screws positioned around the perimeter—to compress the lid against a gasket seal. As you tighten each screw, the cover plate presses down evenly, deforming the gasket material into a continuous seal that blocks dust, water, and contaminants.

This compression-based sealing delivers the tightest environmental protection available in junction box covers. Manufacturers rate screw-on boxes up to IP68 (submersible) and IP66 (high-pressure jet resistance) because the mechanical compression ensures consistent gasket contact even under external water pressure or dust infiltration attempts. The EECOL Hoffman 6×6×4 screw-close enclosure, for example, achieves IP66 with an oil-resistant gasket compressed by perimeter screws.

Key advantages:

- Maximum IP rating capability: Compression sealing supports IP65 (dust-tight, low-pressure jets) through IP68 (continuous immersion). If your application demands the highest ingress protection—coastal installations, washdown environments, underground vaults—screw-on covers deliver.

- Vibrasjonsmotstand: Unlike snap-fit clips that can deform and loosen under shock loads, screw attachments maintain secure closure in high-vibration environments. Industrial motor control boxes, rail-mounted equipment, and machinery enclosures benefit from this retention strength.

- Security and tamper resistance: Screw fasteners require tools to open, deterring casual tampering. Some manufacturers offer tamper-resistant screw options (Torx, security hex) for locations where unauthorized access is a concern. Standard Phillips or hex screws still provide a basic security layer compared to tool-free designs.

- Gasket compatibility: Screw compression works with various gasket materials—silicone, EPDM rubber, closed-cell foam, even formed-in-place foam gaskets (FIPFG). You can match gasket composition to chemical exposure: oil-resistant for machinery environments, UV-stable for outdoor installations, low-temperature silicone for cold climates.

Trade-offs you’re accepting:

- Slow access time: Removing and reinstalling four to six screws takes 2-3 minutes per maintenance visit. Over the life of a high-access installation, this compounds into significant labor time. One facility engineer calculated that switching twenty screw-cover junction boxes to hinged designs saved forty hours of technician time per year.

- Screw management: Field techs often lose cover screws during maintenance. They get dropped into cable trays, left on equipment, or stored in pockets and forgotten. Missing screws compromise the seal and require trips to retrieve replacements.

- Tool dependency: Every access requires a screwdriver (Phillips, hex, or Torx depending on fastener type). In emergency troubleshooting or quick visual inspections, this adds friction to the workflow.

- Material and cost: Screw-on junction boxes span a wide price range. Basic polycarbonate units with screw covers start around $8-15 for small sizes, while high-spec stainless steel IP68 enclosures run $60-250 depending on dimensions and features. The Polycase ZQ-080804 screw-close outdoor box lists at $58.60, reflecting mid-range pricing for a quality polycarbonate enclosure with gasket and hardware.

Snap-On Covers: Tool-Free Installation and Quick Access

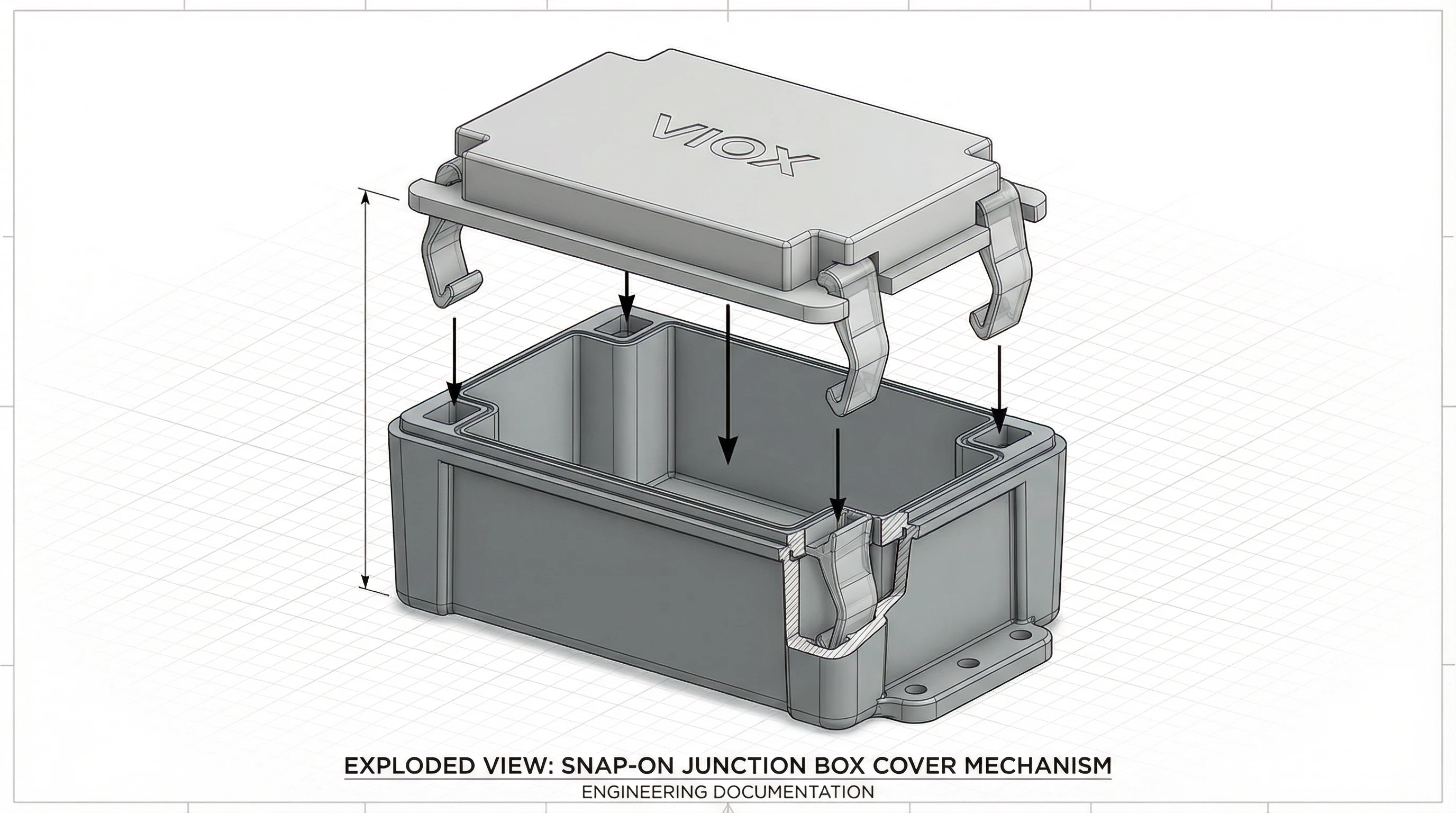

Snap-on covers eliminate threaded fasteners in favor of spring clips or molded locking tabs built into the cover and base. You align the lid, press down firmly, and the clips engage with an audible snap. Opening reverses the process—squeeze the release tabs or pry the cover edge, and the lid pops free. No screwdriver required.

This tool-free design prioritizes installation speed and maintenance efficiency. The Spelsberg HP80/HP100 snap-lid junction box exemplifies the category: integral stepped cable entries, IP55 rating, and 100% tool-free assembly marketed as a time-saving solution for residential and light commercial installations. For installers running dozens of boxes per day, eliminating screw handling compounds into real labor savings.

Key advantages:

- Fast installation: Snap-on covers install in 30-60 seconds compared to 2-3 minutes for screw types. On a hundred-box residential project, this saves over two hours of installer time. Multiply across thousands of units, and the efficiency gain becomes material.

- Tool-free operation: No screwdriver means one less tool to carry and no stripped screw heads from overtightening or cheap hardware. Maintenance techs can pop the cover for a quick visual inspection without digging through their tool bag.

- Cover retention: Unlike screw covers that get set down during maintenance and sometimes forgotten, snap-on lids stay captive during inspection—you hold the cover while checking connections, then snap it back. This reduces lost-cover incidents in low-security environments.

- Kostnadseffektivitet: Snap-on junction boxes often target the budget-conscious segment. Eliminating threaded inserts and hardware reduces manufacturing cost, translating to lower unit prices—often $5-20 for typical residential sizes. The Hylec Debox V line positions snap-close boxes as “extra value” products with emphasis on faster, cheaper installation.

Trade-offs you’re accepting:

- IP rating limitations: Most snap-on covers top out at IP55 (dust protected, low-pressure water jets) or IP65 (dust-tight, low-pressure jets). You’ll rarely see IP66+ or IP68 in snap-lid designs because friction-fit gasket seals can’t match the compression force of screw-down covers. For high-pressure washdown or submersible applications, snap-on covers fall short.

- Reduced vibration resistance: Spring clips rely on elastic deformation to maintain engagement. In high-vibration environments—motor mounts, machinery panels, rail equipment—the clips can fatigue and loosen over time. Snap-fit design guidance explicitly flags loosening under deformation and drop-test failures as known failure modes. One plant engineer reported snap-on covers opening spontaneously on conveyor-mounted junction boxes after six months of operation.

- Security concerns: Tool-free access is a double-edged feature. Any unauthorized person can open the box by pressing the release tabs. For public-access locations or critical systems, this lack of tamper resistance is a dealbreaker.

- Gasket seal limitations: Snap-on covers typically use friction gaskets or pre-compressed foam seals rather than high-compression designs. Over time and repeated openings, the gasket compresses permanently and loses sealing effectiveness. Screw-compressed gaskets can be re-torqued; snap-fit gaskets degrade faster.

- Application sweet spot: Indoor residential, protected commercial spaces, and temporary installations where ease of access outweighs maximum environmental protection. Not recommended for outdoor exposure beyond sheltered soffits or vibration-heavy industrial environments.

Hinged Covers: Permanent Attachment for High-Frequency Access

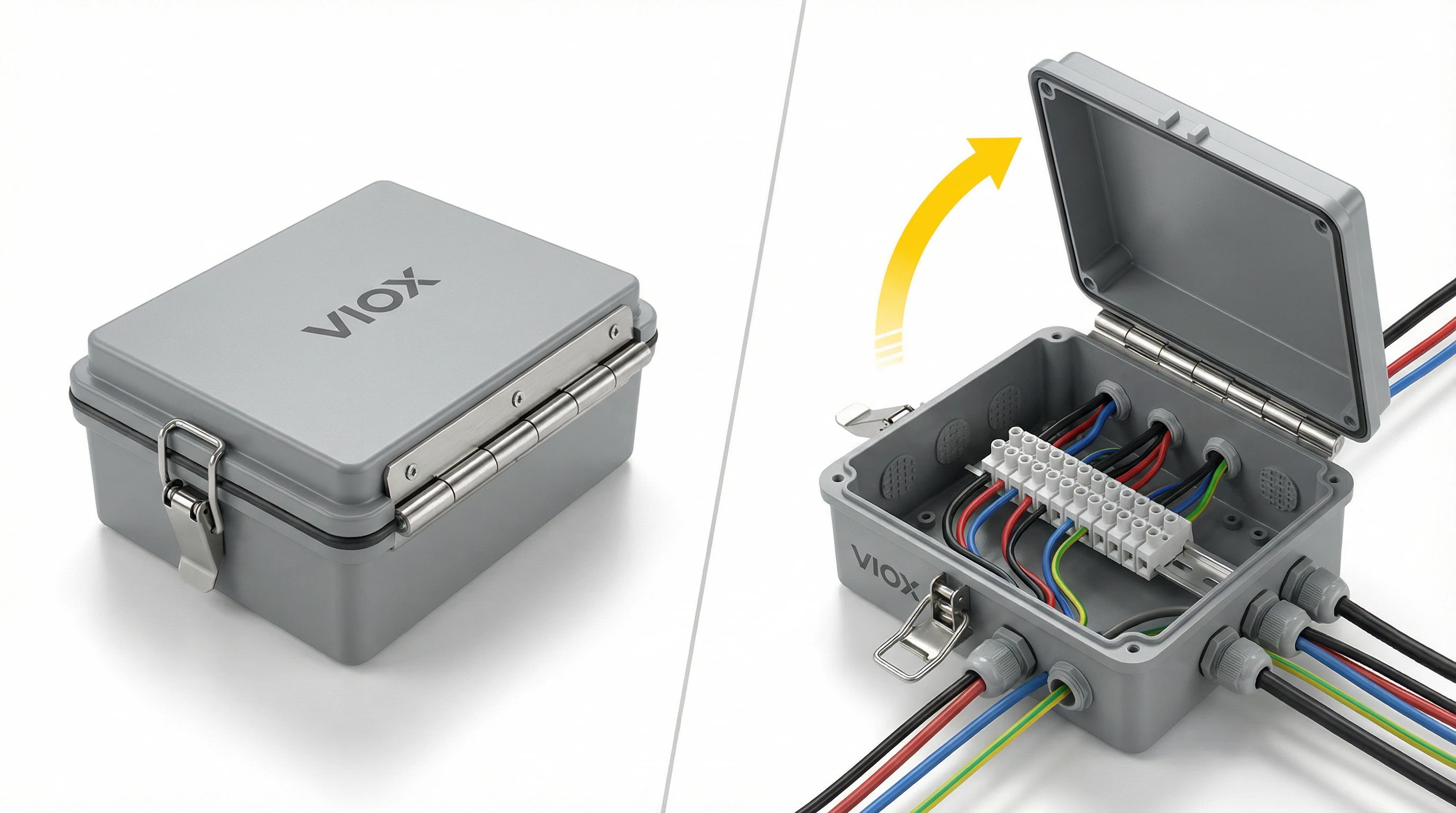

Hinged covers combine the environmental protection of screw-on designs with the access speed of snap-on lids. A stainless steel or reinforced polymer hinge attaches one edge of the cover to the box base, while latches or clips secure the opposite edge. To open, you release the latch and swing the lid up; the hinge keeps the cover captive and often includes a stay-open feature so the lid doesn’t swing closed mid-inspection.

This captive-lid design solves the lost-cover problem endemic to removable covers while maintaining IP66 sealing capability when properly gasketed. The Polycase ZH series hinged junction boxes, for example, use stainless steel latches and achieve outdoor-rated NEMA 4 specifications (roughly equivalent to IP66) despite the hinged construction.

Key advantages:

- Captive cover design: The hinge permanently attaches the lid to the base, making it physically impossible to lose the cover. In high-access installations—control panels with weekly sensor checks, industrial junction boxes inspected during every line changeover—this eliminates cover-loss incidents and the resulting seal compromises.

- Fast repeat access: After initial installation (2-3 minutes to mount the enclosure), every subsequent access takes 10-20 seconds: flip the latch, swing open, inspect, swing closed, latch. No screws to remove, no clips to engage—just one motion. Multiply this across twenty accesses per year, and you’ve saved thirty minutes of technician time per box.

- High IP ratings available: Unlike snap-on covers, hinged designs can achieve IP66 (high-pressure jets) and IP67 (temporary immersion) when equipped with compression gaskets. The hinge mechanism doesn’t compromise sealing on the latched edges because the latch applies compression force similar to screw fasteners.

- Stay-open functionality: Many hinged covers include friction hinges or prop mechanisms that hold the lid at 90-120 degrees. This frees both hands during maintenance—critical when you’re checking terminal tightness or tracing conductors in a crowded panel.

- Profesjonelt utseende: Hinged enclosures project a more finished, equipment-grade aesthetic compared to snap-on boxes. For visible installations in commercial buildings or client-facing areas, the hinged design communicates quality.

Trade-offs you’re accepting:

- Cost premium: Hinged junction boxes typically cost 15-30% more than equivalent screw-on models due to the hinge hardware and more complex molding/assembly. The Polycase ZH-060604 hinged box lists at $56.31 versus similar-size screw models in the $40-50 range. This premium pays for access efficiency and cover retention.

- Større fotavtrykk: The hinge mechanism adds width to one side of the enclosure. In space-constrained panels or tight conduit runs, this extra dimension can complicate mounting. Check hinge clearance requirements before specifying.

- Hinge durability concerns: Plastic hinges on budget enclosures can fatigue and crack after hundreds of open/close cycles. Stainless steel hinges are more durable but add cost. For ultra-high-frequency access (multiple times daily), even quality hinges will eventually wear.

- Latch failure modes: The latch is the single point of closure. If the latch breaks or deforms, the entire cover becomes insecure. Screw-on covers distribute closure load across multiple fasteners; hinged designs concentrate stress on the latch mechanism.

- Application sweet spot: Installations requiring frequent planned access—monthly sensor inspections, weekly terminal checks, control system troubleshooting—where maintaining IP66 protection matters but you want to avoid the labor tax of screw removal. Also ideal for areas where covers routinely get misplaced.

Cover Type Comparison: Side-by-Side Specifications

| Funksjon | Screw-On | Snap-On | Hinged |

| Attachment Method | 4-6 threaded fasteners | Spring clips or molded tabs | Hinge + latch/clip |

| Installasjonstid | 2-3 minutes | 30–60 sekunder | 2-3 min (first), 10-20 sec (repeat) |

| Tool Requirement | Screwdriver (Phillips/hex/Torx) | None (hands only) | None after initial install |

| Typical IP Rating | IP65-IP68 | IP54-IP65 | IP65-IP67 |

| Vibrasjonsmotstand | Utmerket | Fair (clips can loosen) | Good (latch-dependent) |

| Security | High (tool required) | Low (tool-free access) | Medium (latch-dependent) |

| Cover Loss Risk | High (removable) | Medium (hand-held) | None (captive hinge) |

| Gasket Sealing | Compression seal | Friction seal | Compression seal |

| Vedlikeholdsfrekvens | Low (annual/quarterly) | Medium (monthly/weekly) | High (weekly/daily) |

| Kostnadsintervall | $8-250 | $5-60 | $50-300 |

Selection rule of thumb: Match cover type to access frequency and environmental exposure. If you’ll open the box more than quarterly, the labor savings of hinged or snap-on covers justify their limitations. If IP66+ and vibration resistance matter more than access speed, screw-on covers are non-negotiable.

Application Selection Guide: Matching Cover Type to Your Installation

Choose Screw-On Covers when:

- Environmental exposure is harsh: Outdoor installations subject to rain, snow, or direct sunlight. Coastal locations with salt spray. Underground vaults. Any location requiring IP66-IP68 protection.

- Vibration is significant: Motor control boxes, conveyor-mounted enclosures, rail equipment, machinery panels. Anywhere shock loads or continuous vibration could loosen snap-fit connections.

- Inspection frequency is low: Boxes opened annually or less. The labor cost of screw removal is negligible at this frequency, and you benefit from maximum sealing and security.

- Security matters: Public-access locations, critical infrastructure, tamper-prone areas. The tool requirement and optional tamper-resistant fasteners deter unauthorized access.

- Chemical exposure exists: Oil mist, coolants, solvents. Screw compression allows matching specialized gasket materials (Viton, EPDM, oil-resistant rubber) to the chemical environment.

Choose Snap-On Covers when:

- Speed is the priority: High-volume residential installations where installer efficiency drives project economics. Temporary setups requiring quick deployment.

- Environment is protected: Indoor locations, climate-controlled spaces, sheltered outdoor areas (under soffits, inside cabinets). Anywhere IP55 protection suffices.

- Access is occasional but unplanned: Troubleshooting scenarios where you need quick visual confirmation without committing to full maintenance procedures.

- Vibration is minimal: Wall-mounted residential boxes, static equipment enclosures, ceiling junction points.

- Budget is constrained: Projects where minimizing enclosure cost matters and environmental protection requirements are modest.

Choose Hinged Covers when:

- Access frequency is high: Weekly sensor checks, monthly terminal inspections, routine system diagnostics. The hinged design pays for itself in labor savings.

- Covers get lost or misplaced: High-traffic maintenance areas, outdoor service locations, installations accessed by multiple technicians. The captive lid eliminates replacement costs and seal compromise.

- You need both protection and access: Applications requiring IP66 sealing with frequent planned maintenance—industrial control panels, outdoor sensor junction boxes, equipment interface points.

- Stay-open functionality matters: Two-handed maintenance tasks—tightening terminals, swapping components, tracing wires—where you can’t hold the cover while working.

- Professional appearance counts: Visible installations in commercial lobbies, client-facing equipment rooms, architectural applications where the enclosure aesthetic matters.

Decision matrix by inspection frequency:

- Annual or less: Screw-on (labor cost negligible, maximize protection)

- Kvartalsvis: Screw-on or hinged (depends on vibration/security needs)

- Månedlig: Hinged (labor savings justify cost premium)

- Weekly or more: Hinged (screw covers create unsustainable maintenance burden)

- Daily/continuous: Consider hinged or re-evaluate if the junction box should be a permanent terminal block instead

Installation Considerations: Tools, Time, and Techniques

Screw-On Cover Installation:

Start with gasket inspection—verify the seal is properly seated in its groove before positioning the cover. Place the lid and finger-tighten all screws in a star pattern (opposite corners first, then remaining screws). This ensures even gasket compression. Torque to manufacturer spec using a screwdriver or low-torque driver; over-tightening crushes the gasket and causes leaks, while under-tightening leaves gaps. Polycarbonate enclosures typically call for 8-12 in-lbs; metal boxes may spec higher. Keep spare screws and a gasket on-site—field experience shows 10-15% of installations eventually need screw replacement due to loss or thread stripping.

Snap-On Cover Installation:

Verify clip alignment by test-fitting the cover before making cable connections—some snap mechanisms require specific orientation. Route cables through knockouts or glands, complete connections, then position the cover at a slight angle and press down firmly starting from one edge. You’ll hear/feel the clips engage sequentially. Tug the cover gently to confirm engagement; a properly snapped lid resists pull-off force. For difficult-to-snap covers in cold weather, warm the enclosure slightly—plastic clips become more pliable above 50°F. Mark the correct cover orientation with a permanent marker if the box geometry isn’t obvious; field techs waste time fighting backwards covers.

Hinged Cover Installation:

The hinge determines enclosure orientation, so plan mounting location with the hinge swing direction in mind—you need clearance for the lid to open 90-120 degrees. Position adjacent equipment or conduit runs accordingly. During initial installation, verify the latch engages fully and the gasket seats evenly around the perimeter. Some hinged covers include adjustable latches; set the compression to achieve a slight gasket squeeze without forcing the latch. Test the stay-open function under load—verify the hinge holds position when you’re leaning on the open lid during maintenance. Lubricate metal hinges annually with light machine oil to prevent binding.

Common installation mistakes across all types:

- Over-torquing screws or latches, crushing gaskets and creating leak paths around deformed seal material

- Installing covers before cable strain relief, putting mechanical stress on internal connections during subsequent access

- Ignoring gasket orientation—some gaskets have directional sealing lips; install them backwards and IP ratings suffer

- Using mismatched replacement covers—verify gasket compatibility and fastener type when sourcing replacements

Maintenance and Long-Term Reliability: Access Frequency Impact

Cover type directly influences maintenance workflow efficiency and long-term seal integrity.

The Maintenance Tax: Every screw-on cover access costs 2-3 minutes in screw handling. For a junction box accessed monthly, that’s 24-36 minutes annually—multiply by twenty boxes, and you’ve spent eight hours per year on fastener removal across a single facility. One industrial plant calculated that converting forty high-access junction boxes from screw to hinged covers recouped the upgrade cost in labor savings within eighteen months.

The Lost Cover Problem: Removable covers—both screw-on and snap-on—get misplaced during maintenance. A technician sets the lid down while tracing a circuit, gets called to another issue, and the cover stays on a cable tray for weeks. The exposed box accumulates dust, moisture, and contamination. Replacement covers often don’t include gaskets, so the seal degrades even after reinstallation. Hinged covers eliminate this failure mode entirely.

Gasket Degradation Rates: Gasket lifespan varies by cover type and access frequency. Screw-compressed gaskets handle 50-100 open/close cycles before compression set reduces sealing effectiveness; high-quality silicone gaskets in outdoor screw-on boxes often last 5-10 years with annual access. Snap-on gaskets degrade faster—friction seals lose 20-30% of their sealing force after 30-50 cycles. For high-access installations, plan gasket replacement every 2-3 years regardless of cover type.

Vibration Failure Patterns: Snap-on covers in vibration environments follow a predictable failure curve. Clips loosen gradually over 6-12 months as plastic deforms under cyclic loading. The cover remains visually closed but the gasket seal fails, allowing dust and moisture ingress before the lid eventually pops open. Screw-on and hinged latched covers resist this failure mode because compression force doesn’t depend on elastic clip deformation.

When to Replace Covers: Look for these end-of-life indicators:

- Cracked or yellowed polycarbonate (UV degradation, typical after 8-12 years outdoor exposure)

- Stripped screw holes in plastic covers (requires cover replacement or threaded insert repair)

- Permanently compressed gaskets that no longer spring back when pressed (seal integrity compromised)

- Broken or fatigued hinges that don’t hold open position or show visible cracks

- Deformed snap clips that require excessive force to engage or pop open spontaneously

Conclusion: Cover Type Selection Checklist

Junction box cover type determines installation efficiency, maintenance burden, and long-term reliability. The decision matrix is straightforward:

Select based on access frequency first:

- Annual or less → Screw-on

- Quarterly → Screw-on or hinged (evaluate other factors)

- Monthly or more → Hinged

- Weekly+ → Hinged or reconsider junction box approach

Then validate environmental requirements:

- IP68 or high-vibration → Screw-on only

- IP66 → Screw-on or hinged

- IP54-IP65 indoors → Any type acceptable

Finally consider operational factors:

- Security/tamper resistance needed → Screw-on with tamper-resistant fasteners

- Cover loss is a problem → Hinged

- Budget is tight → Snap-on (but verify IP and vibration limits)

- Professional appearance matters → Hinged

The cover type you choose today sets the maintenance workflow for the next decade. Spend an extra $10-30 per box on hinged covers for high-access locations, and you’ll recover the investment in labor savings within two years. Specify screw-on covers where environmental protection and vibration resistance trump access speed. Use snap-on covers for protected, low-access residential installations where speed matters more than maximum sealing.

VIOX Electric manufactures junction boxes across all three cover types, engineered to match your application requirements. Contact our technical team for cover type recommendations based on your specific installation environment and maintenance patterns.