The $43,000 Lesson

Tuesday, 3:47 PM. Mark’s phone buzzes with a photo from his warehouse manager.

The 20-foot container just cleared customs. Inside: 5,000 AC contactors from his new Chinese supplier. The samples were flawless three months ago. CE certified. Tested to AC-3 standards. Contacts smooth as glass.

The warehouse photo shows something different. Contact surfaces pitted like lunar craters. Coil housings cracked. Three units with springs missing entirely.

Mark’s calculator already knows the math: $43,000 in unusable inventory, plus $8,200 for expedited replacement orders from his backup supplier, plus the two canceled purchase orders from customers who couldn’t wait three months for the redo.

Total damage: $51,200. Recovery time: four months.

The sample-to-bulk quality gap isn’t a myth. It’s the #1 reason importers lose money on Chinese electrical goods. And here’s what most buyers don’t know: it’s often not fraud. It’s far more complicated than that.

As a Chinese electrical equipment manufacturer, I’m going to explain exactly why this happens, show you the cultural and economic forces at play, and give you the three-stage quality control system that prevents these disasters. Some of this will make Chinese suppliers look bad. That’s intentional. You need to know what you’re dealing with.

Why Your Perfect Sample Became a Defective Bulk Order

The Sample Line Trick (And Why It’s Not Always a Trick)

Most Chinese factories have two types of production lines:

- The Sample Line: Experienced workers. Premium components. Extra inspection time. This is where your flawless sample was born.

- The Production Line: Mixed skill levels. Cost-optimized components. Pace pressure. This is where your bulk order was made.

Buyers assume they’re the same. They’re not. Here’s the uncomfortable truth: many factories genuinely don’t think this matters. From their perspective, both products “work” – they just have different cosmetic standards. Which brings us to the cultural factor that Western buyers struggle to understand.

The Chabuduo Trap

Chabuduo (差不多) roughly translates to “close enough” or “good enough.” It’s not laziness. It’s a cultural attitude toward acceptable variance. When a factory manager says chabuduo about a minor cosmetic defect, they’re not being dismissive – they genuinely believe the product is acceptable for use. Western standard: The contact surface must be smooth, with no visible pitting or discoloration. Chabuduo standard: The contact surface works electrically. Small pits don’t affect the 10,000-cycle rating. Chabuduo. Your specification says “smooth.” Their definition of smooth is different. You see a defect. They see a functional unit that costs $0.40 less to produce. The gap isn’t malicious. It’s definitional. And it costs importers millions annually.

The 30% Payment Gamble

Standard payment terms for Chinese suppliers: 30% deposit, 70% on delivery. Here’s what happens behind the scenes:

At 30% payment: Factory prioritizes your order. Quality is monitored. Timeline is sacred. After 70% payment: Your leverage vanishes. Quality pressure shifts to the next order with 30% pending.

The harsh reality? Once a factory has your 70% balance payment in hand, addressing quality issues becomes optional. Sure, they’ll fix catastrophic failures to maintain relationships. But those marginal defects you wouldn’t have accepted during sampling? Chabuduo. Timing matters. Quality control MUST happen before final payment clears.

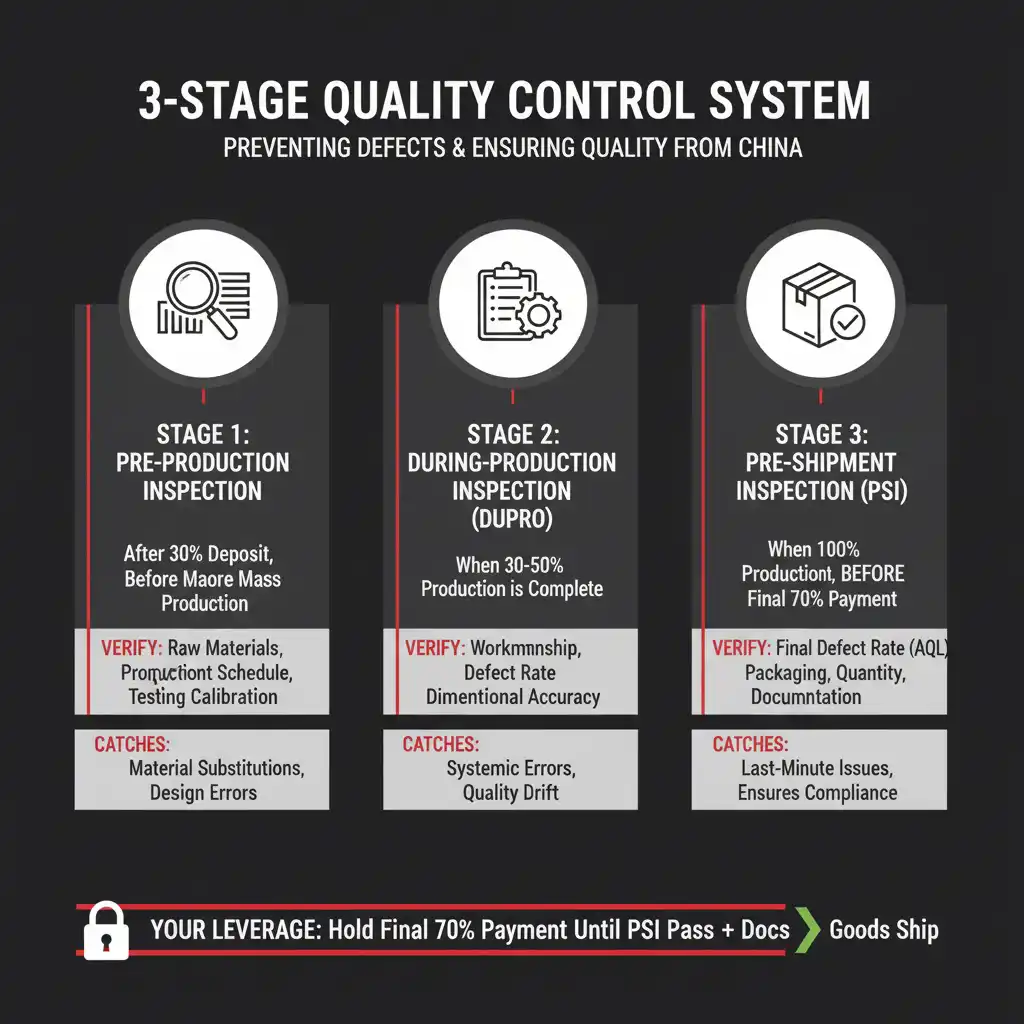

The Three-Stage Quality Control System That Actually Works

Forget the standard advice about “find a good supplier.” Here’s the system that prevents the sample-to-bulk gap, backed by 30+ years of manufacturing experience.

Stage 1: Pre-Production Inspection (Before Manufacturing Starts)

Timing: After you pay the 30% deposit, before mass production begins. What to verify:

- Raw material specs match your purchase order (copper content in contacts, plastic grade for housings)

- Component sourcing (brand-name vs. generic equivalents)

- Production schedule and line assignment

- Testing equipment calibration status

Why this matters: Factory representatives will show you approved components during negotiation. Then procurement substitutes cheaper alternatives when production starts. The contact block that was meant to be silver-alloy? Now it’s tin-plated copper. The difference costs them $0.35 per unit. The difference costs you product failures in 6-12 months. How to do this:

Hire a local inspection agency (SGS, Intertek, Bureau Veritas). Cost: $300-500 per inspection. Alternative: Request dated photos of raw materials with your PO number visible.

Pro-Tip #1: Specify component brands in your contract. “Silver-alloy contacts” is too vague. “Silver-alloy contacts meeting IEC 60947-4-1 Annex C material specifications, verified by XRF testing” leaves no room for chabuduo.

Stage 2: During-Production Inspection (DUPRO)

Timing: When 30-50% of production is complete. What to verify:

- Workmanship quality matches samples

- Defect rate tracking (target: <2% for electrical components)

- Assembly process follows specifications

- Dimensional accuracy on critical parts

Why this matters: This is where the wheels fall off. Production pace accelerates. Worker fatigue sets in. Quality discipline slips. By inspecting at 30-50% completion, you catch systemic issues while there’s still time to correct them. Inspect at 100% completion? Too late. The 70% payment deadline is breathing down your neck, and the factory knows it. Real scenario: A German buyer ordered 10,000 MCCBs. During DUPRO at 40% completion, inspection found inconsistent terminal torque – some screws barely finger-tight. Factory claimed it was the inspector’s fault for checking before final QC. But without that DUPRO? Those undertorqued terminals would have caused connection failures within months. How to do this:

Schedule DUPRO for 35-40% completion (sweet spot for detection + correction time). Focus on:

- Terminal connections (torque test random samples)

- Component alignment (contacts, springs, actuators)

- Marking/labeling accuracy

- Function testing (trip curves, actuation force)

Pro-Tip #2: Request a “first article inspection” report for the first 50-100 units produced. This establishes the quality baseline before the entire batch is made.

Stage 3: Pre-Shipment Inspection (PSI)

Timing: When 100% of production is complete, before final payment. What to verify:

- Final defect rate (AQL sampling standards)

- Packaging quality (damage prevention)

- Quantity accuracy

- Documentation completeness (CE certificates, test reports, DoC)

Why this matters: This is your last line of defense. The factory has completed production. The shipment is ready. Your 70% balance payment is pending. If you skip PSI and discover defects after customs clearance, your options are:

- Accept the defects (lose money)

- Negotiate a discount (still lose money)

- Ship everything back (lose even more money)

All bad options. How to do this:

Use AQL (Acceptable Quality Level) standards: AQL 2.5 for critical defects, AQL 4.0 for major defects. Random sampling from multiple cartons/pallets (not just the ones they show you). Live inspection with photo documentation. Pass/Fail decision: Clear criteria established before inspection starts.

Pro-Tip #3: Include a “re-inspection” clause in your contract. If PSI fails, factory must fix defects and allow a second PSI at no additional cost to you. Otherwise, factories will claim PSI failures are “too subjective.”

Red Flags That Scream “Quality Problems Ahead”

Twenty years in this industry teaches you which supplier behaviors predict disaster. Watch for these warning signs:

Red Flag #1: “We Don’t Need Inspections”

What they say: “We have ISO 9001 certification. We do our own QC. Third-party inspection is unnecessary expense.” What it means: They know their production quality is inconsistent. They don’t want you to see it. Reality check: Legitimate factories WELCOME inspections. It protects both parties. Resistance to inspection = hide something.

Red Flag #2: Reluctance to Share Factory Videos/Photos

What they say: “Factory photos are confidential. Trade secret concerns.” What it means: They might be a trading company, not a manufacturer. Or the factory conditions are poor. Reality check: Real manufacturers proudly show their facilities. If you can’t get a virtual factory tour, assume they’re hiding something.

Red Flag #3: Samples Arrive Too Quickly

What they say: “Samples ready in 3 days!” What it means: Those aren’t YOUR samples. They’re stock samples kept on hand for all potential customers. Reality check: True custom samples with your specifications require 2-3 weeks. Fast samples = generic products dressed up.

Red Flag #4: Price Is Suspiciously Low

What they say: “We can offer 40% below market price.” What it means: Corners will be cut. Material substitutions will happen. Quality will suffer. Reality check: Manufacturing has floor costs. Raw materials, labor, overhead, testing – these don’t vanish. Rock-bottom prices guarantee rock-bottom quality.

The 97% Failure Rule:

Only 3% of consumer electronics startups successfully launch products manufactured in China. The primary cause? They chose suppliers based on price alone. Then discovered that cheap became expensive very quickly.

How to Choose a Supplier (The VIOX Approach)

What to Look For

- Manufacturing Experience (5+ years minimum) Established factories have stable processes. New operations are still figuring things out. You don’t want to be their learning experience. Verification method: Business license with establishment date, customer reference checks, factory visit history.

- Export Track Record to Your Target Market Factories that export to Europe understand CE requirements. Factories that export to North America understand UL/FCC. First-time exporters to your market will make expensive mistakes. Verification method: Request customer references from your region, ask about their certification maintenance procedures.

- Certification Legitimacy CE marking is self-declared. Any factory can print it on a label. But proper CE marking requires: Technical file documentation, EU Declaration of Conformity (DoC), Test reports from accredited labs, Traceability records. Verification method: Request technical file samples BEFORE ordering, Verify lab accreditation (CNAS for China, UKAS for UK, A2LA for US), Cross-check certificate numbers with issuing bodies.

- Quality Management System ISO 9001 is table stakes. Look for: ISO 9001:2015 (latest revision), Industry-specific certifications (IECEE CB Scheme for electrical products), Regular audit history. Red flag: Certificates with no audit history, or certifications that expired years ago but still displayed.

- Communication Quality If your sales contact can’t explain technical specifications clearly, imagine dealing with quality issues later. Test: Ask detailed technical questions during negotiation. Strong responses = strong organization. Vague answers = weak technical depth.

The Documentation Shield

Quality control prevents defects. Documentation protects you when defects slip through anyway. Essential Documents (Demand These Before Final Payment)

- Test Reports from Accredited Labs Electrical safety testing (IEC 60947 series for contactors/MCCBs, IEC 60898 for MCBs) EMC testing (if applicable) RoHS compliance (for EU sales) Report must show: Test lab accreditation, test date, specific model tested, pass/fail results.

- EU Declaration of Conformity (DoC) Legal document stating compliance with EU directives Must include: Manufacturer details, product identification, applicable directives, signature and date Template available from EU Commission website.

- Technical File (for CE marking) Product drawings and specifications Bill of materials Risk assessment User manual Test reports Traceability records.

- Material Certificates Material composition for critical components (contacts, terminals, housings) Verification method: XRF testing reports, supplier material certificates.

- Production Records Batch traceability (which raw material batch went into which production lot) QC inspection records during production Test data for every unit (where applicable) or sampling data.

Pro-Tip #4: Request these documents DURING production, not after. Factories “preparing documents” after production often means “creating documents” – which is fraud.

What VIOX Does Differently (And Why It Matters)

Let me be direct: most Chinese electrical suppliers operate exactly as I described above. Sample lines. Chabuduo standards. Documentation created retroactively. VIOX Electric broke from this pattern 30 years ago. Here’s how:

- Single Production Standard We eliminated sample lines. Every contactor, MCCB, and relay rolls off the same production line using the same components and inspection standards. Your sample IS your bulk order.

- Western-Trained QC Team Our quality control managers spent 3-5 years working for European electrical companies. They understand that “functional” isn’t enough – cosmetic quality matters. Packaging matters. Documentation matters.

- Pre-Shipment Documentation Every order over 1,000 units includes: Full technical file, Batch-specific test reports, Signed DoC, Material traceability certificates. You get these BEFORE final payment. Not after.

- Third-Party Inspection Welcome We’ve worked with SGS, Intertek, Bureau Veritas, and TÜV for decades. Schedule inspections whenever you want. No advance notice required. We have nothing to hide.

- Transparency Policy If we can’t meet a specification, we tell you BEFORE accepting the order. If production encounters issues, you hear about it immediately – not when the shipment arrives defective.

Action Plan: Your Next Import

Phase 1: Supplier Selection (Week 1-2)

Identify 3-5 potential suppliers on Alibaba, Made-in-China, Global Sources. Request certifications, customer references, factory videos. Eliminate suppliers with red flags (no factory tour, suspiciously cheap, poor communication). Shortlist 2-3 candidates.

Phase 2: Sample Evaluation (Week 3-5)

Order samples from all shortlisted suppliers. Test samples thoroughly (don’t just look at them). Request full documentation package for sample units. Evaluate sample-to-documentation consistency.

Phase 3: Contract & Terms (Week 6-7)

Negotiate clear quality standards (reference specific IEC standards). Include 3-stage inspection clauses (pre-production, DUPRO, PSI). Specify component brands/materials with verification methods. Set documentation delivery timeline (before final payment). Define re-inspection terms for failed QC.

Phase 4: Production Monitoring (Week 8-12)

Pay 30% deposit. Schedule pre-production inspection. Schedule DUPRO at 35-40% completion. Review DUPRO report, address any issues immediately. Schedule PSI at 100% completion.

Phase 5: Pre-Shipment Verification (Week 13-14)

Attend PSI (or receive inspection report with photos). Verify all documentation is complete and accurate. Release final 70% payment ONLY after PSI pass + documentation received. Confirm shipping arrangements.

Phase 6: Post-Arrival Verification (Week 15-16)

Conduct receiving inspection at your warehouse. Test random samples from multiple cartons. Verify actual defect rate matches PSI findings. Document any discrepancies immediately (with photos).

The Uncomfortable Truth About Chinese Manufacturing

Here’s what most import guides won’t tell you: Chinese electrical goods aren’t inherently low quality. The manufacturing capability is world-class. The engineering expertise is deep. The production scale is unmatched. The quality gap emerges from three sources:

- Cultural definition differences: Chabuduo vs. Western precision standards

- Economic pressure: Buyers demand impossible prices, factories cut corners to meet them

- Inspection gaps: Buyers skip verification steps, factories respond predictably

Fix the third problem, and the first two become manageable. The factories that maintain consistent quality? They’re the ones whose customers demand it through contract terms, enforce it through inspections, and pay fair prices that don’t require corners to be cut. You want Chinese manufacturers to meet Western standards? Define those standards explicitly. Verify them systematically. Pay enough to make them achievable. Or, find a supplier like VIOX that already operates to those standards.

Alumine Rida

Importing electrical goods from China saves 40-70% compared to domestic suppliers. Those savings are real. But they vanish instantly if your 5,000-unit shipment arrives with 15% defects. The sample-to-bulk quality gap isn’t inevitable. It’s preventable through:

- Clear specifications (reference standards, not adjectives)

- 3-stage quality control (pre-production, DUPRO, PSI)

- Documentation verification (before final payment)

- Supplier selection (track record over price)

Most importers fail because they skip these steps. Don’t be most importers. VIOX has manufactured electrical components for 15+ years. Our customers in Europe, North America, and Asia rely on consistent quality because we eliminated the sample line trick, trained our QC teams to Western standards, and welcome third-party inspections. Ready to import electrical goods without the $43,000 lessons? Contact VIOX Electric for supplier qualification support, technical specifications, and transparent manufacturing partnerships.