Introduction

A. Overview of power distribution in electrical systems

An essential component of electrical systems, power distribution makes it possible for electrical energy to be efficiently transferred from sources to different loads. In order to ensure performance, safety, and dependability, this process entails controlling the flow of electricity through various components. Bus bars and terminal blocks are important parts of this system since they have different functions in power distribution and organization.

B. Importance of choosing the right solution

Making the right power distribution solution choice is essential to maximizing system performance and guaranteeing security. The decision between terminal blocks and bus bars can have a big impact on total efficiency, maintenance, and installation complexity. Engineers and technicians can make well-informed decisions that are suited to particular applications by being aware of their differences.

Understanding Bus Bars

A. Definition and basic concept

In electrical power distribution systems, bus bars—metal strips or bars—are used to gather and transport electricity from incoming feeders to outgoing feeders. They act as a focal point where several electrical connections come together, making it possible to regulate huge current loads effectively. In electrical systems, bus bars—which are usually composed of conductive materials like copper or aluminum—are crucial for lowering resistance and decreasing power losses.

Additional video content for busbars.

B. Key features of bus bars

- High Current Capacity: Bus bars are perfect for heavy-duty applications because they are made to withstand large currents

- Low Resistance: Because of their sturdy construction, they have low electrical resistance, which lowers energy losses during transmission

- Compact Design: Bus bars take up less space than traditional wiring techniques, making installation easier

- Effective Heat Dissipation: The design allows for better cooling, preventing overheating during high current loads

- Flexibility: They can be arranged in different ways to meet different electrical distribution needs.

C. How Bus Bars Work

Usually housed within switchgear or panel boards, bus bars serve as conductors that gather electric power from incoming sources and distribute it to multiple outgoing circuits. This allows for easy circuit branching at various points along the busway, and in the event of a fault, circuit breakers can disconnect the affected section, ensuring system reliability.

D. Types of Bus Bar Arrangements in Power Systems

- Single Bus Bar Arrangement: Involves one bus bar connected to all equipment. While simple and low-maintenance, a fault affects the entire supply.

- Main and Transfer Bus Arrangement: Utilizes two bus bars with a coupler to allow load transfer between them. This setup maintains supply continuity during maintenance or faults but is more costly.

- Double Bus Double Breaker Arrangement: Features two bus bars and two circuit breakers for enhanced reliability and flexibility, ensuring uninterrupted supply during maintenance.

- One-and-a-Half Breaker Arrangement: Involves three circuit breakers for two independent circuits, allowing easy addition of circuits but with higher maintenance costs.

- Ring Main Arrangement: Forms a closed loop, providing redundancy; if one section fails, the system continues operating through another path, though it limits future expansion

Understanding Terminal Blocks

A. Definition and basic concept

A terminal block, sometimes referred to as a connection terminal or terminal connector, is a modular part intended to hold two or more cables together inside an insulated frame. This assembly facilitates well-organized wire terminations and connections, offering a dependable and easily accessible method of managing electrical circuits in a variety of settings, especially in control panels and electrical cabinets.

To see these principles in action, we recommend this informative YouTube video on terminal block techniques.

B. How terminal blocks work

The way terminal blocks work is by offering a safe place to connect wires. Every terminal in the block is made to hold a wire firmly in position; to guarantee a strong connection, screws or clamps are sometimes used. The passage of electricity or electrical signals between various circuits is made possible by the clamping down that occurs when wires are put into the terminals. This approach improves safety by eliminating inadvertent disconnections in addition to simplifying wiring.

C. Key features of terminal blocks

- Modular Design: Terminal blocks can be easily expanded or modified by adding or removing terminals based on requirements.

- Insulation: The insulating body protects against accidental contact with live wires, enhancing safety.

- Mounting Options: Many terminal blocks are designed for DIN rail mounting, allowing for easy installation and organization within electrical panels.

- Versatility: They accommodate various wire sizes and types, making them suitable for diverse applications.

- Easy Access: Terminal blocks allow for straightforward troubleshooting and maintenance due to their organized layout

D. Types of terminal blocks

- Single Level Pass-Through Terminal Block: Connects two wires together for simple wire-to-wire junctions.

- Dual Level Terminal Block: Stacks two levels of terminals to save space while allowing multiple connections.

- Multi-Level Terminal Block: Offers three or more levels for even more connections in a compact form.

- Ground Terminal Block: Specifically designed to connect wires to ground, ensuring safety and compliance with electrical standards.

- Fuse Terminal Block: Incorporates a fuse within the block to provide overcurrent protection without needing external fuses.

- Push-In Terminal Block: Allows easy wire insertion without tools; often requires ferrules for secure connections.

- Insulation Displacement Connector (IDC): Connects wires without stripping insulation; sharp blades cut through insulation to make contact.

- Pluggable Terminal Block: Features a plug-and-socket design for quick disconnects, useful in applications requiring frequent maintenance

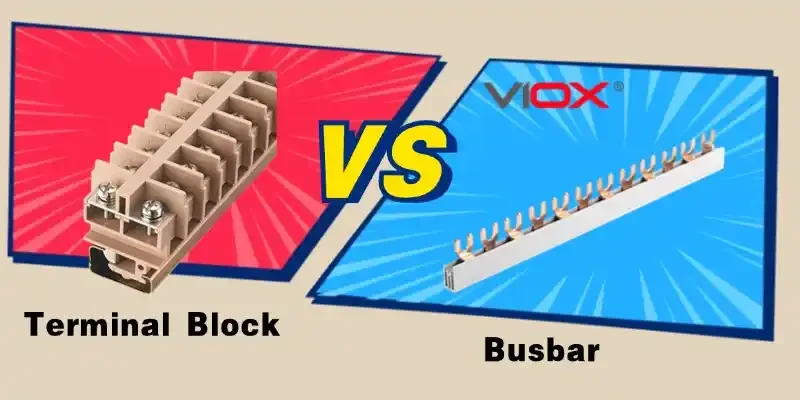

Comparison: Bus Bars vs. Terminal Blocks

A. Power Handling Capabilities

- Bus Bars: Bus bars are made for high current applications, and because of their sturdy design and low resistance, they can effectively handle large power loads. Typically, they are employed in heavy-duty settings where they can handle high currents with little voltage drop, like substations and industrial machines.

- Terminal Blocks: Although terminal blocks may accept a wide range of wire sizes and kinds, their average current carrying capacity is lower than that of bus bars. They work well in smaller-scale applications where neat wiring is necessary, but they might not be the best choice for high-power distribution.

B. Space Requirements

- Bus Bars: These parts provide a space-saving option for power distribution by enabling several connections in a small area. Because of their design, they require less extensive wiring, which saves space when it comes to electrical panels.

- Terminal Blocks: Because terminal blocks are modular, with each terminal separated, they take up more physical space. Compared to bus bars, this may result in a bulkier installation, particularly in applications with plenty of connections.

C. Flexibility and Modularity

- Bus Bars: Bus bars are a reliable way to distribute power, but once placed, they are less modifiable than terminal blocks. It can be more difficult to add or remove connections.

- Terminal Blocks: The modularity and flexibility of terminal blocks are excellent. Adding or removing terminals can readily extend or modify them, which makes them perfect for applications that need to be changed or troubleshooted frequently.

D. Cost Considerations

- Bus Bars: Because they require specialist installation and have higher material prices, bus bars can often be more expensive up front. But over time, these early expenses can be mitigated by their durability and effectiveness in high-power applications.

- Terminal Blocks: Terminal blocks are generally a more economical option than bus bars when it comes to smaller installations. Their reduced initial cost makes them desirable for projects with limited funds, but if regular adjustments are required, they may result in increased maintenance expenses.

E. Suitability for Different Applications

- Bus Bars: Ideal for high-current applications where efficiency and dependability are crucial, such as power distribution in industrial settings, renewable energy systems, and electrical substations

- Terminal Blocks: Ideal for control panels, wiring junctions, and smaller electrical systems where organization and simplicity of access are valued. They are widely utilized in circumstances needing regular adjustments or troubleshooting

| Feature | Bus Bars | Terminal Blocks |

|---|---|---|

| Design | Solid piece of metal | Segmented with individual terminals |

| Circuit Type | Single circuit for multiple connections | Multiple independent circuits |

| Current Capacity | High current capacity with low resistance | Lower current capacity per terminal |

| Installation | Compact and straightforward | Requires more space due to individual terminals |

| Heat Dissipation | Effective due to solid design | Limited; relies on airflow around terminals |

Conclusion

In conclusion, both bus bars and terminal blocks play crucial roles in power distribution systems, each with its unique strengths and applications. Bus bars excel in high-current, industrial settings where space efficiency and heat dissipation are critical. They offer a robust solution for large-scale power distribution needs. On the other hand, terminal blocks shine in scenarios requiring frequent modifications, easy access for maintenance, and organization of multiple smaller circuits. The choice between the two depends on factors such as current capacity requirements, space constraints, flexibility needs, and budget considerations. Understanding these differences enables engineers and technicians to make informed decisions, ensuring optimal performance, safety, and efficiency in their electrical systems. Ultimately, the right choice between bus bars and terminal blocks can significantly impact the overall reliability and effectiveness of a power distribution system.

Reference

https://en.wikipedia.org/wiki/Busbar

https://www.reddit.com/