Cable glands are essential mechanical devices designed to secure and protect cables as they enter electrical equipment, serving multiple critical functions including providing strain relief, environmental protection, and maintaining electrical continuity. These versatile components come in various types and materials, each tailored to specific applications and environmental conditions, making them crucial for ensuring safe and reliable electrical installations.

I.Core Functions and Safety

- Environmental contaminants

- Mechanical stress

- Electromagnetic interference

- Chemical exposure

- Fire and explosion risks

II. Types of Cable Glands

A. Plastic cable glands

Made from materials like nylon or PVC, these glands are lightweight and resistant to corrosion. They are often used in applications where chemical exposure is a concern.

B. Metal cable glands

Typically made from brass or stainless steel, these glands offer durability and strength, making them suitable for harsh environments where mechanical protection is critical.

C. Explosion-proof cable glands

Used in hazardous environments where flammable gases or dust may be present, these glands are designed to contain any sparks or flames within the gland itself, preventing ignition of surrounding materials.

D. EMC cable glands

These glands are designed to prevent electromagnetic interference (EMI) from affecting sensitive electronic equipment. They typically feature additional shielding to maintain signal integrity.

E. Armored cable glands

These are used for cables with protective armouring (such as steel wire). They ensure that the armour is properly connected to ground, providing both mechanical protection and electrical safety.

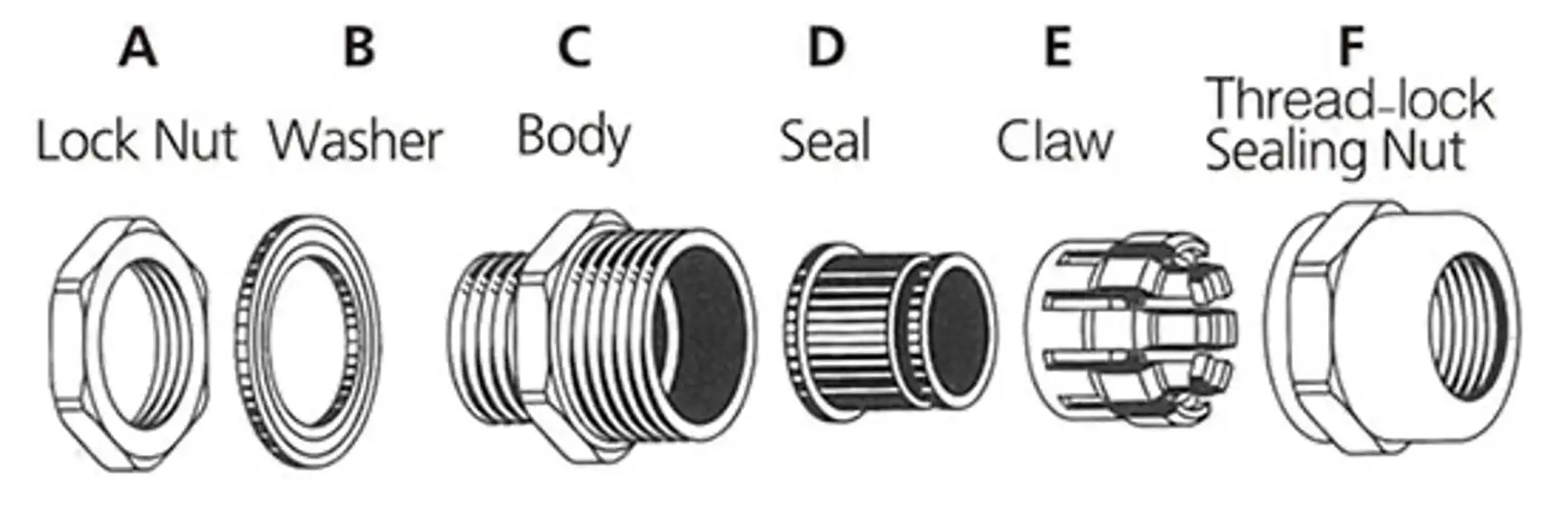

III. Key Components of a Cable Gland

A. Lock Nut

B. Washer

C. Body

D. Sea

E. Claw

F. Thread-lock Sealing nut

IV. Protection Ratings

IP54:Protection: Dust-protected and protected against splashes of water.

IP55:Protection: Dust-protected and protected against water jets.

IP56:Protection: Dust-tight and protected against powerful water jets.

IP66:Protection: Dust-tight and protected against heavy seas or powerful water jets.

IP67:Protection: Dust-tight and protected against temporary immersion in water (up to 1 meter).

IP68:Protection: Dust-tight and protected against continuous immersion in water beyond 1 meter.

V. Choosing the Right Cable Gland

A. Key Factors in Choosing Cable Glands

1、Application Environment:

Indoor vs. Outdoor: Determine whether the installation will be indoors or outdoors, as this affects the required NEMA rating for protection against moisture, dust, and other environmental factors.

2、Corrosive Environments:

If the gland will be exposed to chemicals or harsh conditions, opt for materials that offer corrosion resistance, such as brass or stainless steel.

3、Cable Type and Size:

Ensure that the cable gland is compatible with the type of cable being used (e.g., armored, unarmored, flexible).

Choose a gland that accommodates the diameter of the cable; refer to manufacturer specifications for size ranges.

4、Ingress Protection (IP) Rating:

Look for an appropriate IP rating that indicates the level of protection against dust and water ingress. For example, an IP68 rating is suitable for applications requiring complete dust tightness and protection against prolonged water immersion.

5、Material:

Common materials include plastic (for lightweight applications), brass (for durability), and stainless steel (for corrosive environments). The choice of material can impact both performance and longevity.

6、Installation Method:

Consider how easy it is to install the cable gland. Some designs may require specific tools or techniques, while others offer quick installation features.

7、Sealing Mechanism:

Evaluate the sealing options available (e.g., rubber seals, grommets) to ensure a secure fit that prevents moisture and contaminants from entering.

8、Standards and Certifications:

Check for compliance with relevant standards such as NEMA or IEC ratings to ensure safety and reliability in your specific application.

B. Thread types

- Metric Threads (M):

- Widely used in Europe and many other regions.

- Common sizes include M16, M20, M25, M32, M40, and M50.

- NPT (National Pipe Thread):

- Commonly used in North America.

- Sizes typically range from 1/2″ to 2″.

- PG (Panzergewinde):

- A German standard thread type.

- Common sizes include PG7, PG9, PG11, PG13.5, PG16, and PG21.

- BSP (British Standard Pipe):

- Used in the UK and other countries.

- Common sizes include 1/2″, 3/4″, and 1″.

| Thread Type | Standard | Measurement | Usage |

|---|---|---|---|

| Metric | ISO | Millimeters | Europe, machinery, automotive |

| NPT | U.S. | Inches | North America, plumbing, gas |

| PG | German | Millimeters | Industrial applications, Europe |

| BSP | British | Inches | Plumbing, hydraulics, UK/Commonwealth |

C.Size Considerations

- Cable Diameter: When selecting a cable gland, ensure that the thread size corresponds with the cable diameter to ensure a proper fit.

- Gland Body Size: The size of the gland body must accommodate the cable insulation and any additional protective coverings.

VI. Installation Best Practices

1、Select the Right Gland: Choose a compatible gland for cable type, size, and environment.

2、Prepare the Cable: Strip insulation carefully to match gland entry requirements.

3、Use Proper Tools: Employ appropriate tools to avoid damage.

4、Follow Manufacturer Instructions: Adhere to specific guidelines and torque settings.

5、Ensure Correct Orientation: Install properly to prevent water ingress.

6、Tighten Securely: Use correct torque, avoiding over-tightening.

7、Check for Sealing: Verify intact seals and absence of gaps.

8、Inspect Regularly: Conduct periodic checks for security and effectiveness.

9、Consider Environmental Factors: Use appropriately rated glands for harsh conditions.

10、Grounding and Bonding: Ensure proper electrical safety measures when required.

VII. Maintenance and Inspection

- Regular Visual Checks:

- Look for wear, corrosion, or damage

- Check seal integrity

- Ensure proper tightness

- Assess environmental conditions

- Maintenance Practices:

- Clean area around glands

- Lubricate if manufacturer-specified

- Replace worn components promptly

- Document all activities

- Conduct electrical testing when applicable

- Inspection Frequency:

- Routine visual inspections: At least semi-annually

- Comprehensive inspections: Annually or biannually, especially in harsh environments

- Key Focus Areas:

- Gland body condition

- Sealing elements

- Tightness of fittings

- Environmental factors affecting performance

VIII. Applications Across Industries

Cable glands are utilized in a variety of applications across different industries due to their ability to secure and protect electrical cables. Here are some common applications:

- Industrial Equipment: Cable glands are frequently used in manufacturing plants and factories to connect electrical cables to machinery, ensuring protection from dust and moisture.

- Electrical Enclosures: They are essential for sealing cable entries in control panels, junction boxes, and other electrical enclosures, maintaining the integrity of the equipment.

- Telecommunications: In telecom installations, cable glands help protect communication cables from environmental factors while providing secure connections.

- Marine Applications: Used on ships and offshore platforms, cable glands protect cables from harsh marine environments, including saltwater exposure.

- Automotive Industry: Cable glands are employed in vehicles to manage wiring harnesses and ensure that electrical systems are shielded from vibrations and moisture.

- Renewable Energy: In solar panels and wind turbines, cable glands secure and protect cables that connect various components of the energy systems.

- Mining Operations: They are used in underground mining equipment to safeguard cables from dust, moisture, and mechanical damage.

- HVAC Systems: Cable glands help in connecting power and control cables in heating, ventilation, and air conditioning systems, ensuring reliable operation.

IX. Safety Considerations

Proper Selection: Choose the appropriate cable gland type and material based on the specific application, cable type, and environmental conditions to ensure optimal performance and safety.

Ingress Protection: Ensure that the cable gland has the correct IP rating for the environment in which it will be used. This protects against moisture, dust, and other contaminants that could lead to electrical failures or hazards.

Mechanical Stress: Install cable glands that provide adequate strain relief to prevent mechanical stress on cables, which can cause damage or disconnection over time.

Grounding: For metallic cable glands, ensure proper grounding to prevent electrical shocks and ensure safety in case of faults.

Sealing Integrity: Regularly inspect cable glands for wear or damage to sealing elements. Compromised seals can lead to ingress of water or dust, increasing the risk of equipment failure.

Correct Installation: Follow manufacturer guidelines for installation to ensure that the cable gland is securely fitted and that all components are properly aligned and tightened without over-tightening, which can damage cables.

Compatibility with Cables: Ensure that the gland is compatible with the specific type of cable being used (e.g., armoured vs. unarmoured) to maintain safety standards.

Environmental Conditions: Consider factors such as temperature extremes, exposure to chemicals, and potential for mechanical impact when selecting and installing cable glands.

Related Article:

Common Cable Gland Installation Problems