Cable gland thread types, including NPT, Metric, and PG, are crucial components in electrical installations, each serving specific purposes and applications. Understanding how to identify these thread types is essential for ensuring proper fit, sealing, and compatibility in various industrial and commercial settings.

NPT Thread Characteristics

NPT (National Pipe Thread) is a widely used thread type in cable gland applications, particularly in North America. These threads are characterized by their tapered profile, which provides a secure seal when properly tightened. The taper of NPT threads is approximately 1/16 inch per inch of thread length, creating a wedge-like fit that enhances sealing capabilities.

NPT threads are identified by their fractional size designations, such as 1/2″ NPT or 3/4″ NPT, which refer to the approximate inner diameter of the pipe or fitting. It’s important to note that these sizes are nominal and do not directly correspond to the actual thread dimensions.

Key characteristics of NPT threads include:

- Tapered profile: The diameter of the thread decreases from the base to the tip, ensuring a tight seal when mated with a corresponding female thread.

- 60° flank angle: Similar to metric threads, NPT threads feature a 60° angle between the flanks of adjacent threads.

- Right-hand thread direction: NPT threads are typically right-handed, meaning they tighten when turned clockwise.

- Self-sealing properties: The tapered design allows NPT threads to create a seal without additional sealants, although thread tape or sealant is often used to enhance the seal and prevent galling.

NPT threads are commonly used in applications requiring liquid-tight or gas-tight seals, making them suitable for various industrial environments. When selecting NPT cable glands, it’s crucial to consider factors such as the required ingress protection (IP) rating and the specific environmental conditions of the installation.

While NPT threads offer excellent sealing properties, they can be more challenging to install and remove compared to straight threads like metric or PG types. This is due to the tapered profile, which can lead to over-tightening if not carefully managed.

Understanding the unique characteristics of NPT threads is essential for proper selection, installation, and maintenance of cable glands in applications where these thread types are prevalent, ensuring optimal performance and safety in electrical installations.

Metric Thread Identification

Metric threads are widely used in cable gland applications, particularly in European and international markets. These threads are characterized by their straight, cylindrical profile and are easily identifiable by their “M” prefix followed by the thread’s outer diameter in millimeters. For example, M20 indicates a metric thread with a 20mm outer diameter.

Metric cable gland threads typically range from M12 to M63, offering a wide variety of sizes to accommodate different cable diameters and installation requirements. The thread pitch, which is the distance between adjacent thread crests, is standardized for each size and is usually not explicitly stated in the thread designation unless it deviates from the standard.

One key feature of metric threads is their 60° flank angle, which is similar to NPT threads but differs from the 80° angle of PG threads. This standardized angle ensures compatibility across different manufacturers and applications.

When identifying metric threads, pay attention to the following characteristics:

- Straight profile: Unlike NPT threads, metric threads maintain a consistent diameter along their length.

- Size markings: Look for the “M” prefix followed by a number representing the outer diameter in millimeters.

- Fine pitch options: Some metric threads may have a finer pitch for specialized applications, indicated by a number after the diameter (e.g., M20x1.5).

Metric threads are known for their precise fit and ease of assembly, making them popular in industries requiring frequent maintenance or equipment changes. They also offer excellent sealing properties when used with appropriate gaskets or O-rings.

Understanding the specifics of metric thread identification is crucial for ensuring proper installation and compatibility in various industrial and commercial settings, especially when working with international standards or equipment.

PG Thread Features

PG (Panzergewinde) threads, originating from German standards, are another common type of cable gland thread with distinct features that set them apart from NPT and metric threads. These threads are characterized by their straight, cylindrical profile and are identified by the “PG” prefix followed by a standardized number (e.g., PG 11, PG 16).

One of the most notable features of PG threads is their 80° flank angle, which differs from the 60° angle found in NPT and metric threads. This wider angle contributes to the thread’s unique profile and affects its sealing properties. PG threads typically have a coarser pitch compared to metric threads, which can be advantageous in certain applications where quick assembly or disassembly is required.

PG thread sizes are standardized and range from PG 7 to PG 48, with each size corresponding to a specific nominal diameter. For example:

- PG 11 has a nominal diameter of 18.6 mm

- PG 16 has a nominal diameter of 22.5 mm

- PG 21 has a nominal diameter of 28.3 mm

It’s important to note that while PG threads are still widely used in some industries and regions, they are gradually being phased out in favor of metric threads in many applications. This shift is primarily due to the international standardization efforts and the versatility of metric threads.

When working with PG threads, it’s crucial to ensure compatibility with the equipment and enclosures being used. Many manufacturers offer adapters or transition fittings to accommodate PG threads in systems primarily designed for metric or NPT connections.

Despite their declining usage, PG threads remain relevant in certain legacy systems and specialized applications, particularly in European markets. Understanding their unique features and sizing conventions is essential for professionals working with diverse cable gland systems or maintaining older equipment.

Visual Inspection Tips

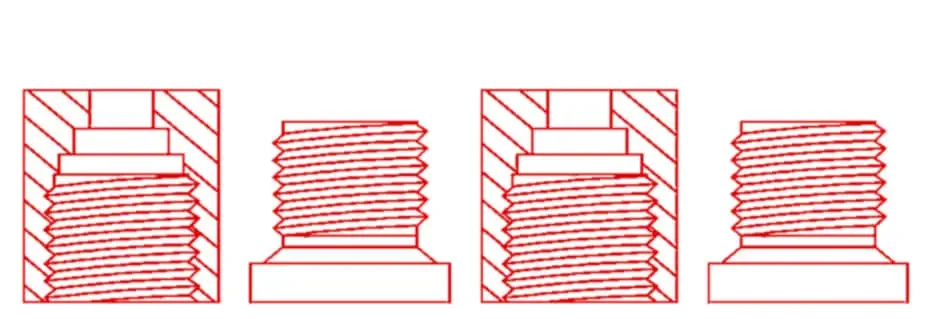

When visually inspecting cable gland threads, focus on key characteristics to accurately identify the type:

- NPT threads: Look for a tapered profile and fractional size markings (e.g., 1/2″ NPT). The threads will appear to narrow towards the end.

- Metric threads: Identify by the “M” prefix followed by the outer diameter in millimeters (e.g., M20). These threads have a straight, cylindrical profile.

- PG threads: Recognize by the “PG” prefix and a standardized number (e.g., PG 11). Note the wider pitch and straight profile.

Pay attention to thread angle, pitch, and overall shape. NPT and metric threads have a 60° flank angle, while PG threads feature an 80° angle. If uncertain, use a thread gauge or consult manufacturer specifications for precise identification.